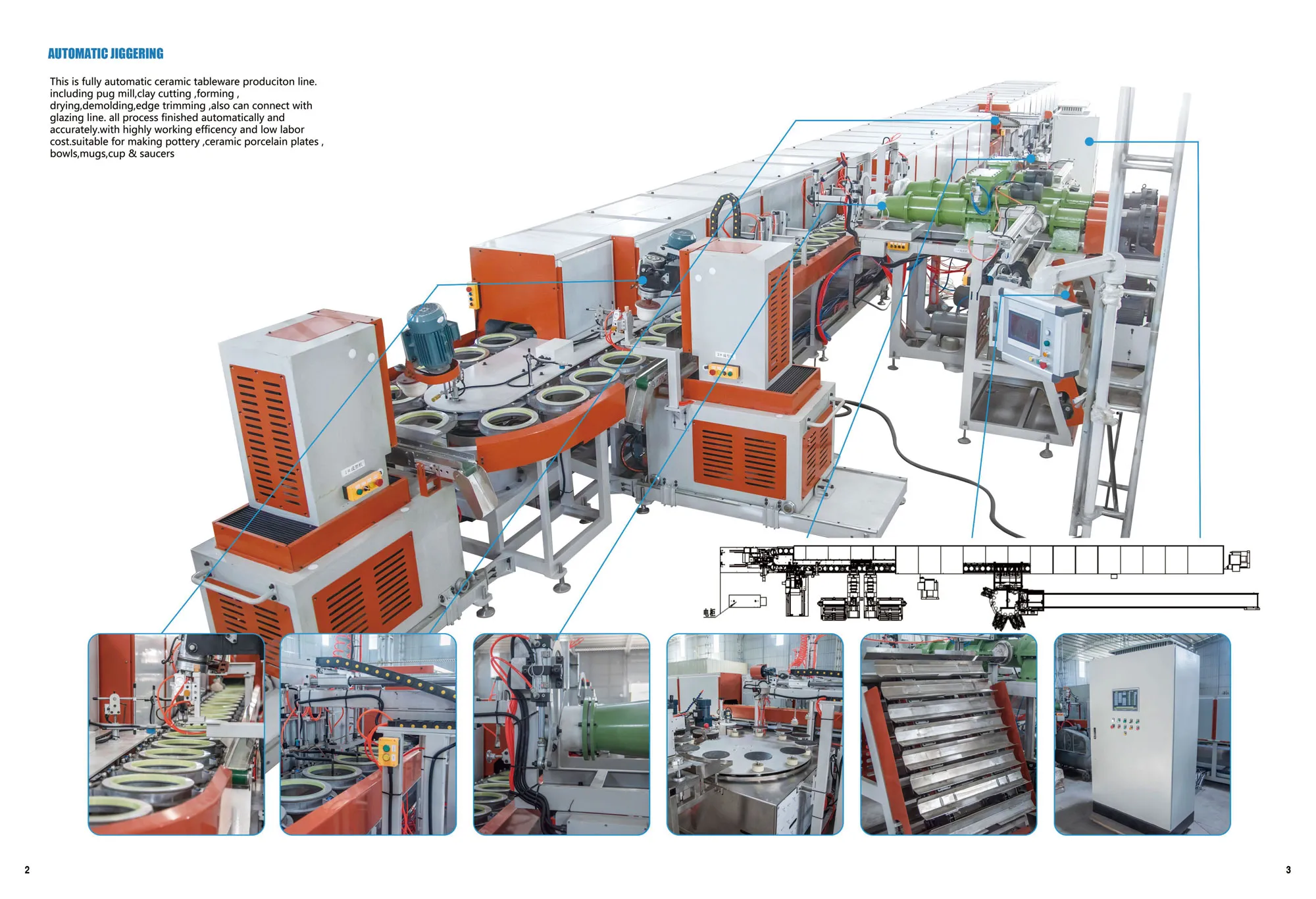

This fully automatic ceramic tableware production line integrates pug mills, clay cutting, forming, drying, demoulding, and edge trimming into one continuous workflow. The system can be connected with a glazing line, enabling precise, high-efficiency, and low-labor-cost production. It is suitable for manufacturing ceramic and porcelain plates, bowls, mugs, cups, saucers, and pottery tableware.

The entire line operates under an integrated PLC control system with an HMI interface, enabling precise, synchronized control of all processes. Advanced transmission technology ensures stable performance, low failure rates, and easy maintenance.

Equipped with premium global brands to ensure reliability and long service life:

All bearings are from NTN, NSK, or SKF, ensuring high precision, smooth operation, and long-term stability.

The drying air duct features a double-layer stainless steel structure with dehumidification, delivering uniform and controlled drying to meet different ceramic process requirements.

A full 304 stainless steel vacuum pug mill ensures stable clay feeding, uniform material quality, and reliable forming performance.

The pneumatic system uses double-layer filtration and high-quality air sources, significantly improving equipment stability and operational consistency.

| MODEL | 250 MODEL | 35O MODEL |

| Max finished the product size | Within a 6-inch bowl and a 7-inch plate (mainly due to the difference in actual shrinkage rate, the reference shrinkage rate of this product is 1.16) | Within a 10-inch bowl and a 10.5-inch plate (mainly due to the difference in actual shrinkage rate, the reference shrinkage rate of this product is 1.16) |

| Forder type (molded billet) | Maximum size of the cup, medium bowl, and dish to φ190mm | Maximum size of cup, medium bowl, and dish to φ290mm |

| Maximum size of gypsum mold (standard) | Yin Mode φ240mm H150mm | Yin mode φ340mm H150mm, Yang mode Yin mode φ340mmH80mm |

| Capacity (PCS/ hour) | 1200 | 600-720According to the actual production requirements) |

| Power | 35KW | 40KW |

| Burner heat | 50,000Kcal/hr | 60,000Kcal/hr |

| Air | 1000L/min | 1000L/min |

| Water | 200L/hr | 200L/hr |

| Moulds | 160 PCS | 160 PCS |

| Dimension | L23000×W4300×H1800 | L31500×W4500×H1800 |

Yutai as a ceramic tableware manufacturer, maintains strict quality standards and excellent service. Revolutionize your manufacturing processes with cutting-edge automation technology that streamlines forming and enhances efficiency.

· Fully or semi-automated machines for flexible production

· High-efficiency lines with intelligent control

· Durable, high-quality materials

· Complete range from forming to finished ceramics

· Over 20 years of experience in ceramic machinery manufacturing

· Excellent engineering R&D team continues to innovate technology

· Export to more than 100 countries and successfully cooperate with 500+ customers

· One-stop ceramic machine solutions tailored to your business needs

· Strict quality inspections lasting a full week for each machine

·Technical support and on-site installation, plus free original factory parts supply