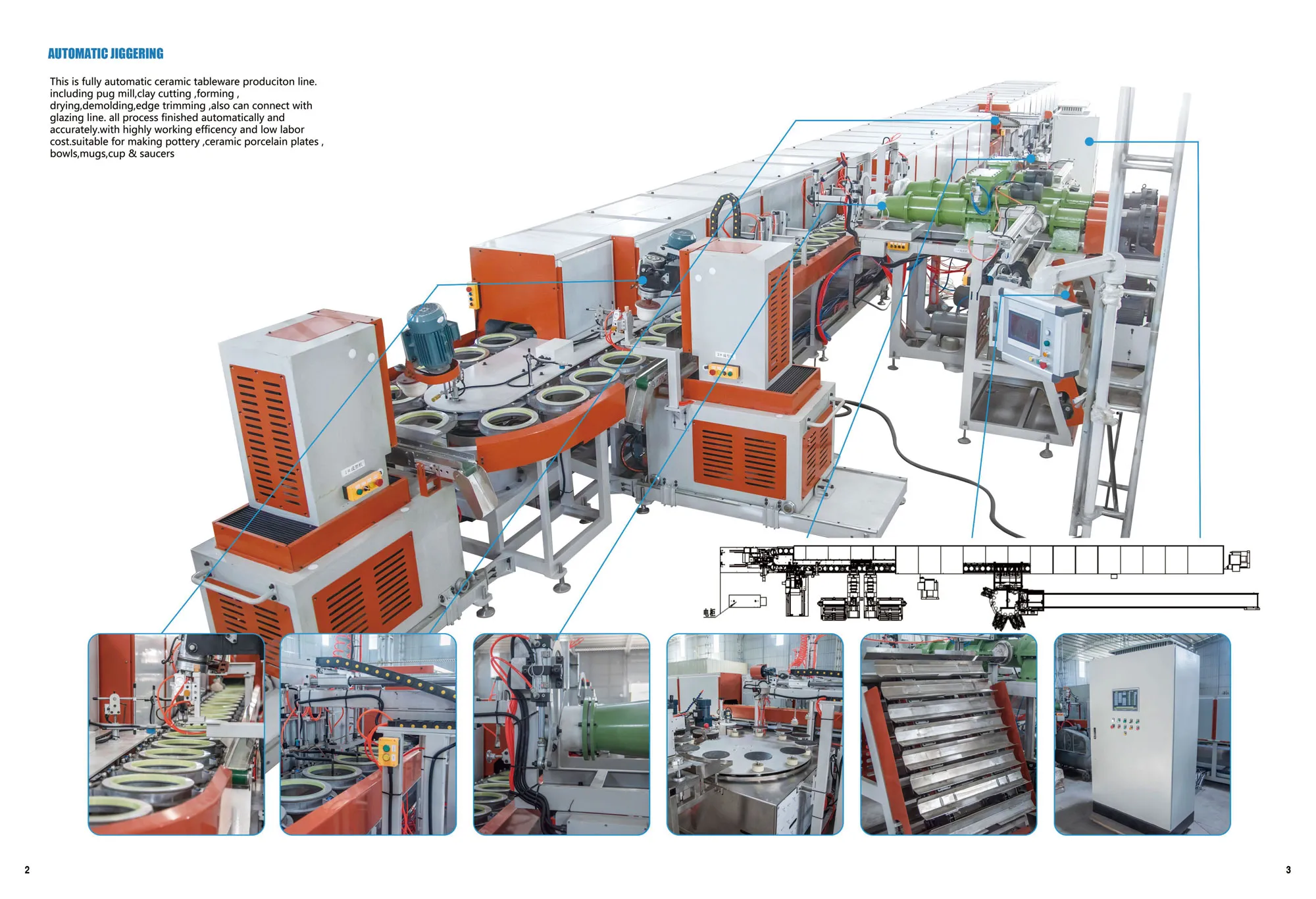

パグミル、粘土切断、成形、乾燥、脱型、縁取りなどの全自動陶磁器食器生産ラインです。すべての工程が自動的かつ正確に終了し、作業効率が高く、人件費が安い。陶器、セラミック磁器プレートボウル、マグカップ、カップ&ソーサーの製造に適しています。

陶磁器機械メーカーとして、優れた陶磁器食器機械とサービスを提供し、お客様の成功をサポートします。

1、全機械はPLC制御システム連結を採用し、全動作は人間と機械のインタフェース制御を実現でき、主伝達は世界の先進技術を採用し、使用性能が優れ、故障率が非常に低く、メンテナンスが便利です;

2、全装置の主要な動力部品はすべてハイエンドの輸入ブランド、日本東芝モーター、日本住友減速機、安川サーボモーター、三菱周波数変換器(またはパナソニック)を使用しています。

3、すべてのベアリングはNTN、NSK、SKF;(または他の高品質のスペアパーツ)です;

4、すべてのシリンダーと空圧制御装置はSMCまたはtecとし、ガイドレールロッドはTaiwan SilverまたはTBIまたはCSKとする。

5、乾燥空気ダクトシステムは二重層ステンレス給気除湿設計を採用し、製品の乾燥効果がより均一で理想的であり、メーカーの異なるプロセスパラメータのニーズを達成する;

6、完全な 304 ステンレス鋼の真空の泥の訓練機械、泥材料の供給の質そして安定性を保障するため

7、すべての空気圧システムは二重層濾過、高品質の電源で、装置の安定性を向上させる;

| モデル | 250モデル | 35O型 |

| 最大完成品サイズ | 6インチボウル、7インチプレート内(主に実収縮率の違いにより、本製品の参考収縮率は1.16です) | 10インチボウル、10.5インチプレート内(主に実収縮率の違いにより、本製品の参考収縮率は1.16となります。) |

| フォアダー型(モールドビレット) | カップ、中鉢、皿の最大サイズはφ190mmまで) | コップ、中鉢、皿の最大サイズはφ290mmまで) |

| 石膏モールドの最大サイズ(標準) | 陰モードφ240mm H150mm、 | 陰モードφ340mmH150mm、陽モード陰モードφ340mmH80mm |

| 容量(PCS/時間) | 1200 | 600-720実際の生産要件に応じて) |

| パワー | 35KW | 40KW |

| バーナーの熱 | 50,000Kcal/時 | 60,000Kcal/時 |

| 空気 | 1000L/分 | 1000L/分 |

| 水 | 毎時200L | 毎時200L |

| 金型 | 160 PCS | 160 PCS |

| 寸法 | L23000×W4300×H1800 | L31500×W4500×H1800 |

Yutaiはセラミック食器メーカーとして、厳格な品質基準と優れたサービスを維持しています。成形を合理化し、効率を高める最先端の自動化技術で、製造工程に革命を起こしましょう。

- 高品質の素材、耐久性と信頼性

- 食器のスタートから完成品まで、完全な製品レンジ

- 高効率生産ラインとインテリジェント制御システム

- セラミック機械産業で20年以上の経験

- 優れたエンジニアリングR&Dチームが技術革新を続ける

- 100カ国以上に輸出し、500以上の顧客と協力する。

- セラミックマシンのワンストップソリューションを提供

- 厳しい品質検査が1週間続く

-テクニカルサポートとオンサイト設置サービス

-オリジナル工場部品無料供給

大手セラミック機械メーカー:

セラミック食器機械の製造に注力しています:粘土製造機、セラミック成形機、乾燥機、釉薬機、セラミックキルン、セラミック印刷機、セラミック底面研削盤など。我々は、各顧客のためのワンストップソリューションと技術サポートを提供します。