The Ceramic Insulator Forming Machine is designed for producing high-quality ceramic insulators used in power systems, especially for transformers and high-voltage applications. With advanced forming technology, stable operation, and precise control, this machine ensures consistent product dimensions, high mechanical strength, and excellent electrical insulation performance. Contact us for a quote and technical support!

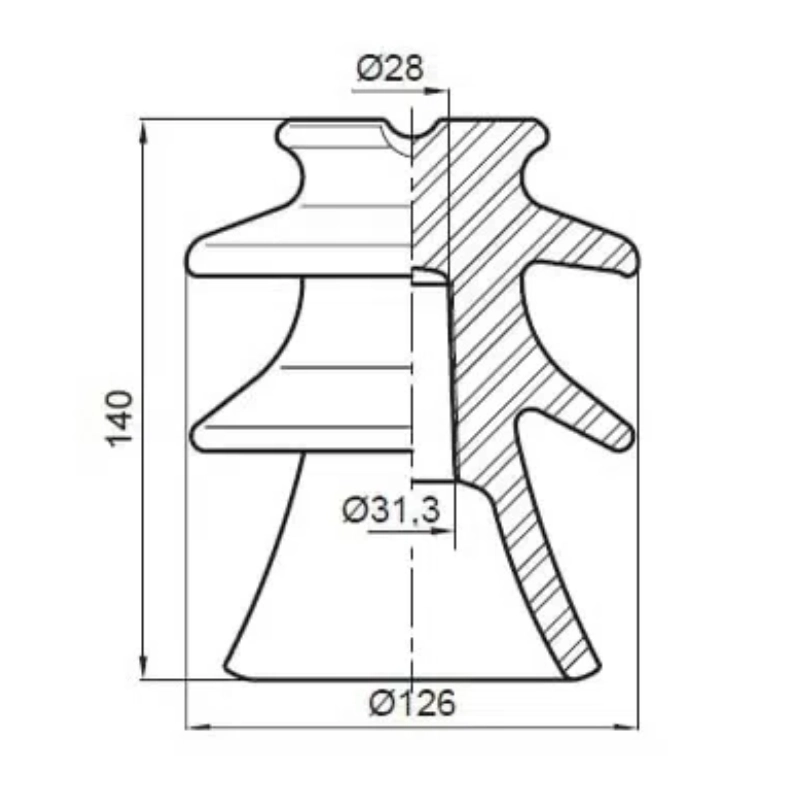

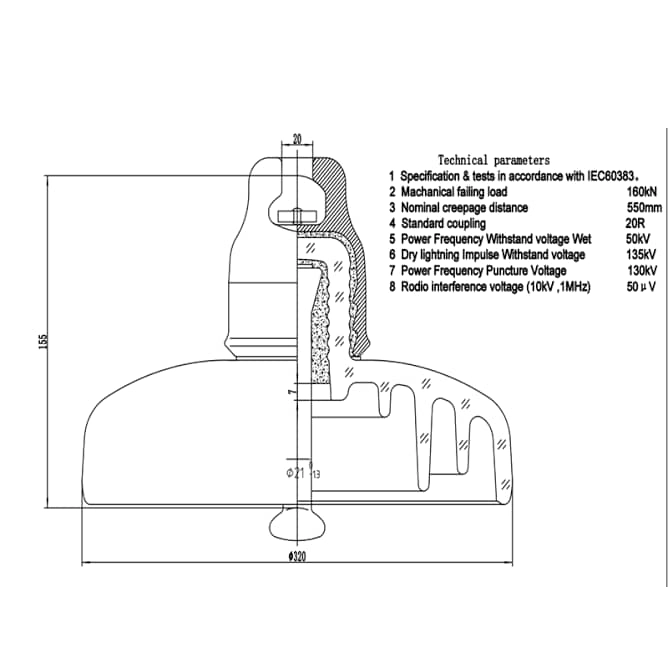

High-precision molding: Ensures uniform shape and size of ceramic insulators and reliable electrical performance.

Automated control system: Reduces manual labor, improves efficiency, and ensures stable production.

Durable construction: Constructed from high-strength materials, it withstands continuous operation and harsh production environments.

Flexible design: Suitable for producing various types and sizes of ceramic insulators used in transformers and power distribution systems.

Easy maintenance: The user-friendly design allows for quick adjustment, cleaning, and repair.

Yutai is a ceramic machine manufacturer that maintains strict quality standards and excellent service. Revolutionize your manufacturing processes with cutting-edge automation technology that streamlines forming and enhances efficiency.

· Fully or semi-automated machines for flexible production

· High-efficiency lines with intelligent control

· Durable, high-quality materials

· Complete range from forming to finished ceramics

· Over 20 years of experience in ceramic machinery manufacturing

· Excellent engineering R&D team continues to innovate technology

· Export to more than 100 countries and successfully cooperate with 500+ customers

· One-stop ceramic machine solutions tailored to your business needs

· Strict quality inspections lasting a full week for each machine

·Technical support and on-site installation, plus free original factory parts supply