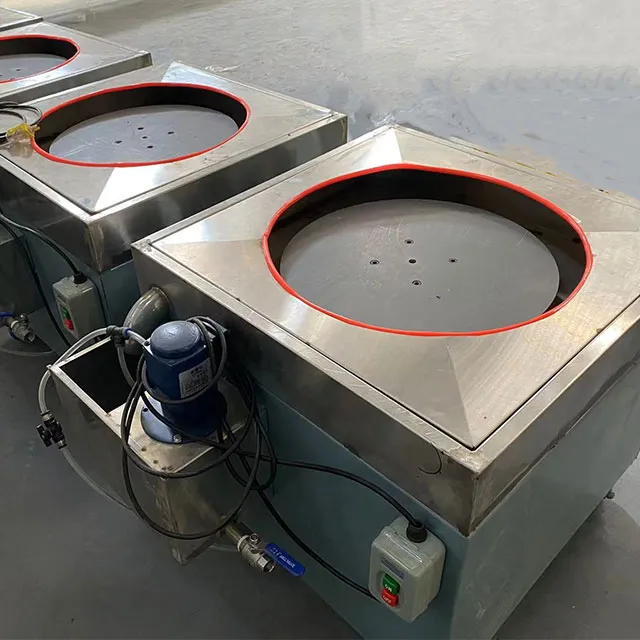

Manual ceramic bottom grinder is used for grinding & trimming the bottom of fired ceramic plate, bowls, mugs, cup, and saucers, etc. with water circulation device to avoid dust.

Precision Grinding: Specifically designed for ceramic bottoms to ensure smooth and even surfaces, enhancing product quality and appearance.

High Production Efficiency: The automated grinding process improves production efficiency, reducing manual intervention and time costs.

Adjustability: Adjustable grinding depth and speed to meet individual customer requirements for different products.

| Model | 400 | |

| Diameter of mesh(cm) | 75x90x80cm(h) | |

| Power(kw) | 200W | |

| Weight(kgs) | 50kgs | |

Yutai as a ceramic tableware manufacturer, maintains strict quality standards and excellent service. Revolutionize your manufacturing processes with cutting-edge automation technology that streamlines forming and enhances efficiency.

· Fully or semi-automated machines for flexible production

· High-efficiency lines with intelligent control

· Durable, high-quality materials

· Complete range from forming to finished ceramics

· Over 20 years of experience in ceramic machinery manufacturing

· Excellent engineering R&D team continues to innovate technology

· Export to more than 100 countries and successfully cooperate with 500+ customers

· One-stop ceramic machine solutions tailored to your business needs

· Strict quality inspections lasting a full week for each machine

·Technical support and on-site installation, plus free original factory parts supply