When it comes to contemporary ceramic production, the accuracy and quality of the pieces rely on the optimal process of forming. Whether the produced items are tableware, bowls, or ornaments, the forming process is the step that gives the product its shape and thus, in turn, impacts the entire drying, glazing, and firing stages. From the perspective of the factory administrator and foreign customers, the optimal rotational forming method is paramount. Jiggering and Jollying are the main ceramic forming processes; we will compare jiggering vs jollying and illustrate how a Yutai Jiggering Machine can improve the efficiency, accuracy, and quality for a modern ceramic factory.

Basic Principles of Jiggering and Jollying

Jiggering Process

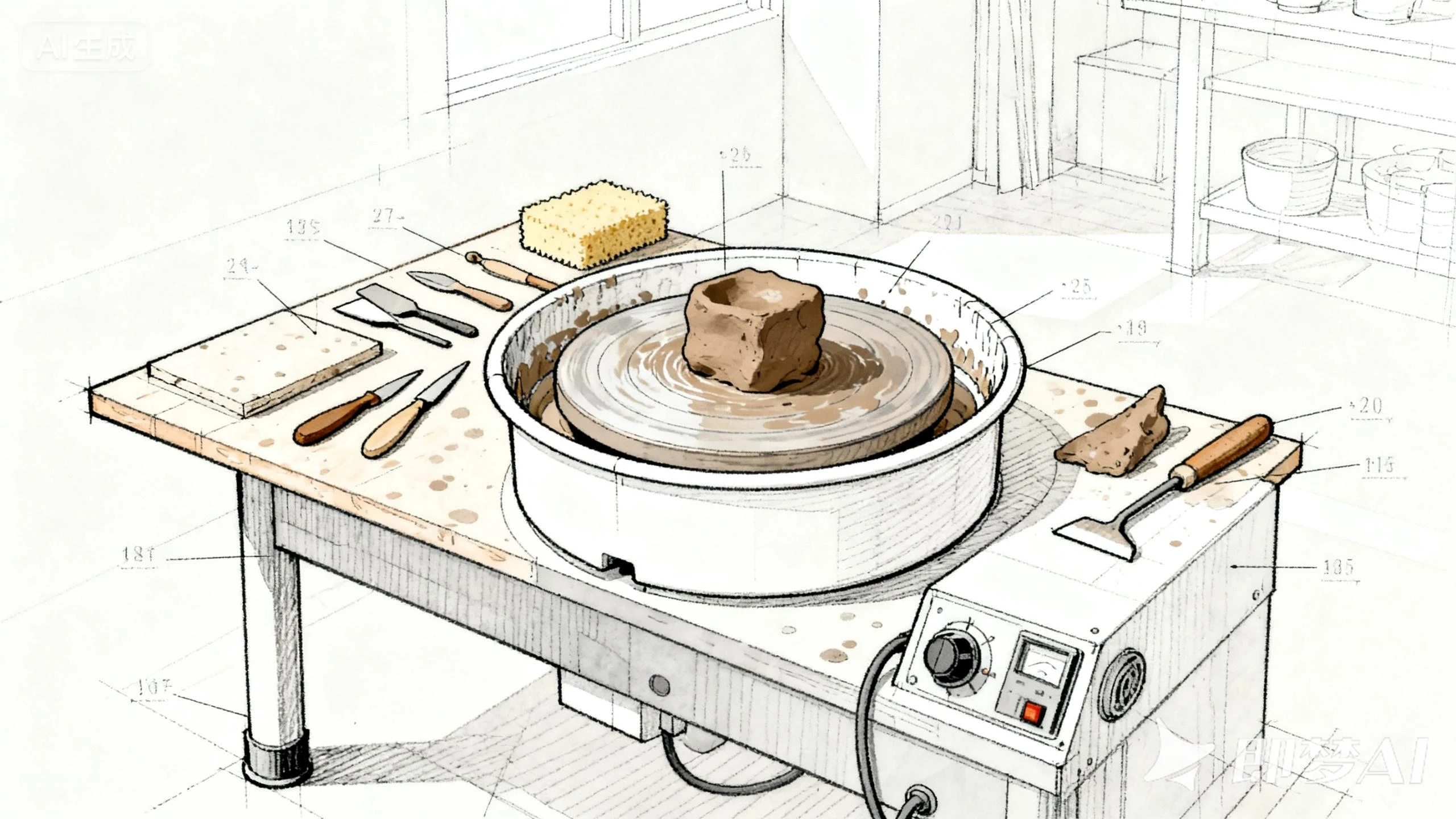

Jiggering is a rotational forming process where a fixed mold is combined with a rotating blade that shapes the clay along the mold’s contour. This method is commonly used for plates, bowls, and trays. The process can be fully automated, from clay feeding and mold rotation to blade shaping, minimizing manual intervention and ensuring high precision. Jiggering produces uniform thickness, smooth edges and is ideal for standardized mass production.

Jollying Process

Jollying is a traditional rotational forming technique. The mold, either upper or lower, rotates while the operator shapes the clay using hand tools or semi-automatic cutters. This method is more labor-intensive and depends heavily on operator skill. Jollying is suitable for small batches or uniquely shaped items such as cups or specialty bowls. However, it is less precise and consistent than Jiggering, and production speed is limited.

Core Differences Between Jiggering and Jollying

To help factory managers and buyers quickly understand the distinctions, here is a multi-dimensional comparison:

| Dimension | Jiggering | Jollying | Notes |

|---|---|---|---|

| Forming Method | Fixed mold + blade shapes clay along the contour | Rotating mold + hand or semi-automatic tools | Jiggering offers higher automation and consistent precision |

| Applicable Shapes | Plates, bowls, trays, standardized shapes | Cups, bowls, special shapes, small batches | Jollying is flexible but less efficient |

| Mold Position | Fixed lower mold, blade shapes from above | Upper or lower mold rotates, operator adjusts | Fixed mold in Jiggering ensures consistent batch production |

| Body Support | Bottom support stabilizes the clay, reducing deformation | Hand-controlled support, less stable | Jiggering provides more stable forming |

| Typical Applications | Tableware, decorative plates, ceramic trays | Cups, small batch bowls, specialty shapes | Jiggering excels in large-scale standardized production |

| Forming Characteristics | Smooth edges, consistent dimensions | Edge quality depends on operator skill | Jiggering achieves higher precision, lower defect rate |

| Thickness Control | Blade automatically shapes clay along the mold, with uniform thickness | Manual control, inconsistent | Jiggering ensures precise thickness, ideal for high-quality ceramics |

| Production Efficiency | Fully automated, high output | Semi-automatic or manual, low output | Jiggering is faster and better suited for high-volume production |

From this table, it’s clear that for standardized, large-scale tableware production, jiggering outperforms jollying in precision, efficiency, and thickness control, while jollying is suitable for small-batch or specialty items.

Advantages of Yutai Ceramic Jiggering Machines

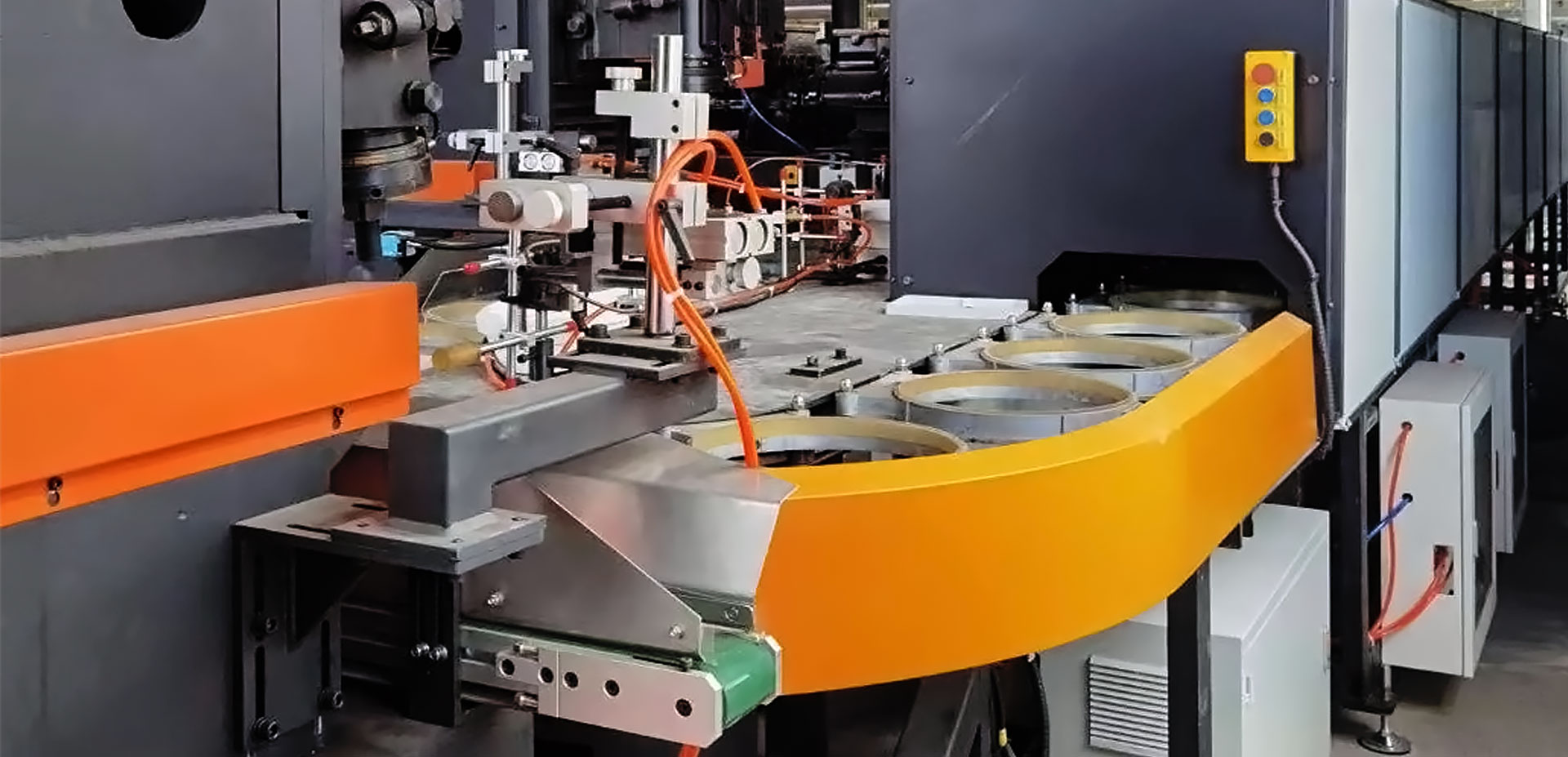

As a professional ceramic machinery manufacturer, Yutai has optimized traditional Jiggering machines to deliver higher automation, customizable solutions, and reduced defect rates.

High Precision and Consistency

Yutai ceramic jiggering machines are equipped with PLC control systems, ensuring precise blade positioning and rotation speed. This guarantees uniform clay thickness and smooth edges for every product. Whether it’s plates or bowls, Yutai machines maintain batch-to-batch consistency and minimize defective pieces.

Automation and Productivity Boost

From automatic clay feeding to mold rotation and blade shaping, the entire process can run fully automatically. Multiple machines can form synchronized production lines, significantly increasing output and reducing labor costs. This is especially advantageous during peak order seasons for overseas buyers.

Customizable Solutions

Yutai provides custom ceramic forming machines, adjusting blades and molds according to product size, thickness, and shape. Whether producing tableware, sanitary ceramics, or decorative items, Yutai Jiggering Machines can deliver precise and consistent results for diverse product lines.

Reduced Defects and Waste

Automated thickness control and stable bottom support effectively minimize clay deformation and defects, boosting finished product yield and reducing raw material waste. This is crucial for factories aiming for high-quality, export-standard production.

Choosing the Right Forming Process for Your Ceramic Factory

When selecting a forming process, consider the following factors:

- Product Type: Plates and bowls are ideal for Jiggering; small-batch or specialty items may use Jollying.

- Production Volume: High-volume factories benefit from Jiggering’s fast cycle time and automation.

- Precision Requirements: High-end tableware or export products require uniform thickness and consistent dimensions, favoring Jiggering.

- Return on Investment (ROI): Although Jiggering machines have a higher initial investment, long-term gains from increased output and lower defect rates deliver higher ROI.

For professional advice and to determine the best ceramic jiggering machine model for your production line, Yutai offers personalized consultation and demo services, ensuring your factory gets a solution tailored to your specific needs.

Conclusion

In summary, Jiggering and Jollying differ significantly in process, applicable shapes, forming method, mold position, body support, typical applications, forming characteristics, and thickness control. For modern ceramic factories pursuing high output, precision, and consistency, Yutai ceramic jiggering machines are the optimal choice. If you are looking to boost productivity, reduce defects, and implement a fully customizable forming solution, contact us today to schedule a free consultation or demo and take your ceramic production to the next level.