陶磁器の艶出しは、陶磁器製品に光沢、色、保護層を与えることができる、陶磁器製造工程の重要な部分です。様々な種類の セラミック艶出し機 様々な生産ニーズに対応し、これらの装置の特性と利点を理解し、最適なグレージングソリューションを選択するのに役立つ。

自動グレージングマシン

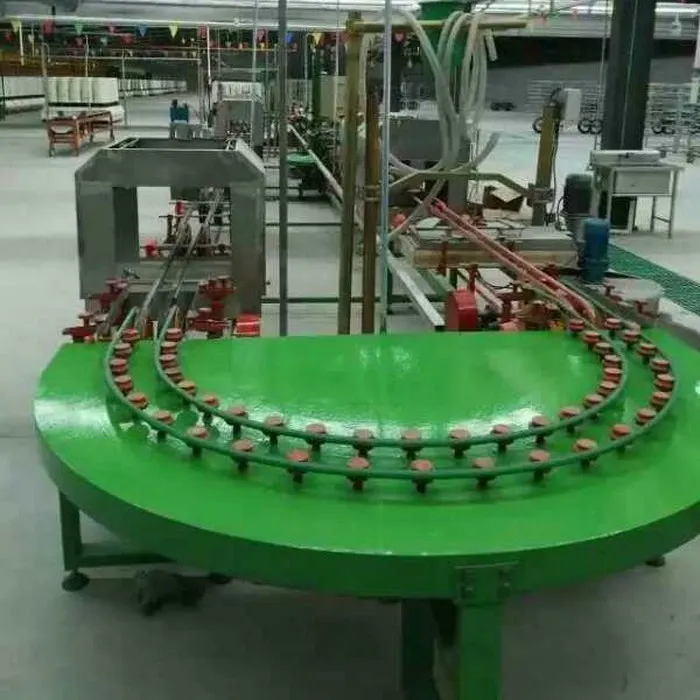

自動施釉機は現代陶磁器生産ラインの最も一般的な設備の一つで、主な特徴は高効率、高精度、一貫性です。大量生産に適しており、様々な形や大きさの陶磁器製品を扱うことができます。主な技術パラメーターは生産速度、釉薬容量、制御システムなどです。

半自動グレージングマシン

半自動グレージングマシンは自動と手動の中間に位置し、効率的で柔軟性がある。中小規模の生産に適しており、特に釉薬と型を頻繁に変更する必要がある生産ラインに適しています。半自動グレージングマシンの主な技術パラメーターは、操作のしやすさと調整の柔軟性です。

釉薬噴霧機

釉薬噴霧機は、ノズルを用いて釉薬を陶磁器の表面に均一に噴霧するもので、複雑な形状や細部の豊かな陶磁器製品に適しています。その利点は、釉薬材料の利用率が高く、釉薬の効果がきめ細かいことにあります。釉薬噴霧機の技術パラメーターは主にノズルの種類、圧力制御、噴霧範囲などである。

釉薬浸漬機

ディップグレージングマシンは、セラミック製品を釉薬槽に浸漬することで施釉を実現するもので、シンプルな形状や大量生産に適しています。操作が簡単で、釉薬の均一性が良いのが特徴です。主な技術パラメーターは浸漬時間、釉薬温度、タンク容量などです。

手動グレージングマシン

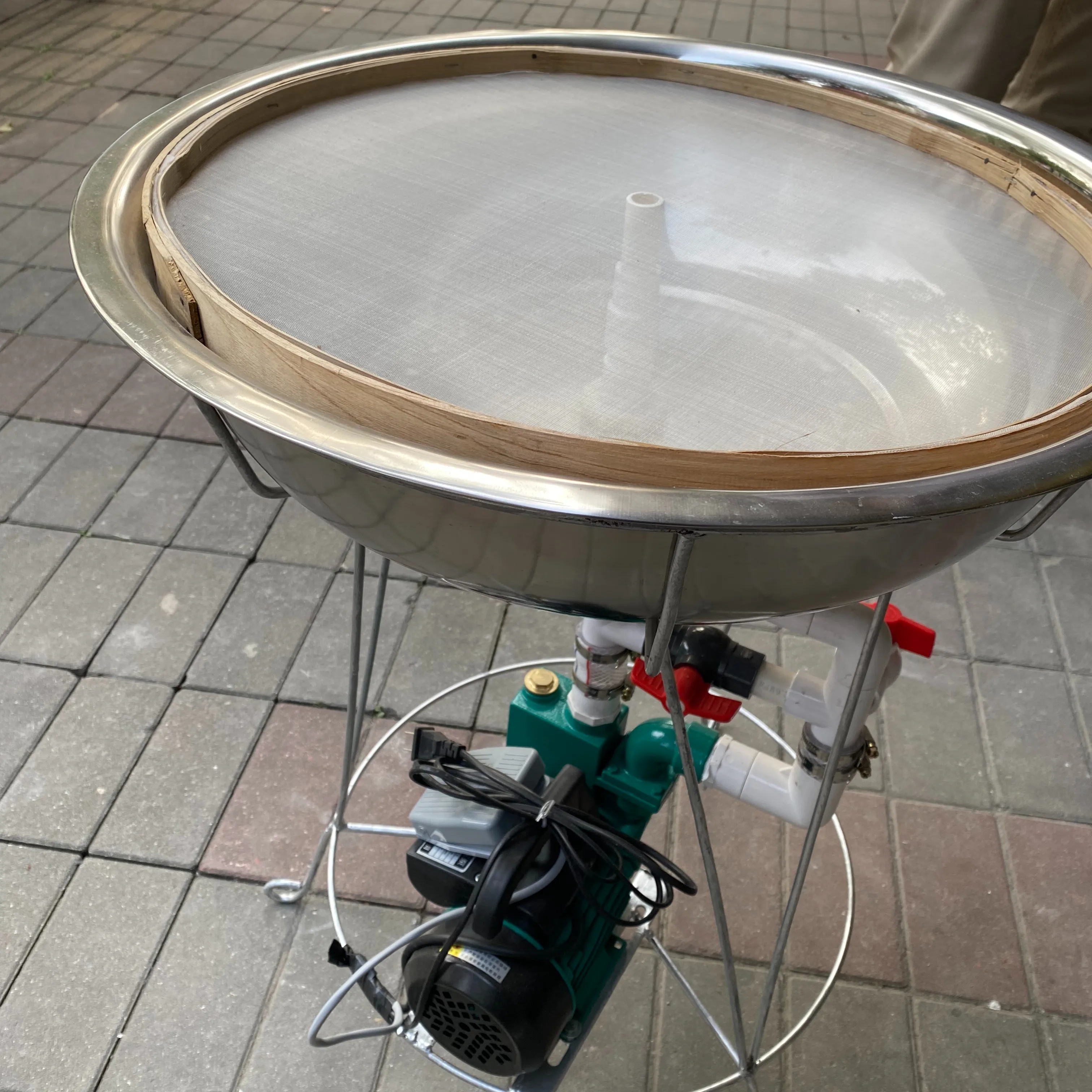

手動釉薬機は、小規模生産とカスタマイズされた生産、特に芸術陶磁器や高付加価値製品に適しています。その利点は、柔軟な操作と低コストです。技術パラメーターは、手動制御の精度と操作の快適さです。

グレージングマシンの選び方

適切なグレージング機械を選ぶには、生産規模、製品タイプ、コスト、メンテナンスなどの要素を考慮する必要がある。大規模生産には自動グレージングマシンが最適であり、多様でカスタマイズされたニーズには手動グレージングマシンやグレージングロボットが適している。

結論

セラミックグレージングマシンは、その種類によって特性や適用範囲が異なり、適切な装置を選択することで生産効率や製品品質を大幅に向上させることができます。日進月歩のセラミック産業において、最新のグレージング技術を理解し適用することは、競争力を維持するための重要な手段です。

雄泰セラミック機械メーカーを専門とする。 セラミック釉薬機械これは、ボウル、プレート、ソーサー、カップ、花瓶を釉薬に適しています。私達はワンストップでカスタマイズされた解決策、技術的な設置サポートおよび顧客が彼らの陶磁器ビジネスを成功させるのを助けるカスタマイズされたサービス指導を提供します!