素焼きの質 最終製品の成功を決定づける重要な要素である。ビスケットの品質変動は クラッキング, 歪み, 密度不均一性, その他の表面欠陥は、焼成に影響を与え廃棄物を発生させる。これらの問題は生産時間を増加させるだけでなく、操業効率にも影響を及ぼす。. プロフェッショナルなセラミック機械メーカー ユタイ機械 不安定なセラミック素焼き品の品質に共通する機械的要因を分析し、当社の先進設備とカスタマイズされたサービスにより、素焼き品の安定性と生産効率を向上させる解決策を提供します。.

不安定なセラミックビスケット品質の一般的な兆候

ビスケットの品質が不安定な場合、通常以下の形で現れます:

- ひび割れまたは亀裂: ビスケットは成形中や乾燥中にひび割れが生じることがあり、焼成後に脆い製品や欠陥品となる可能性があります。.

- 不均一な密度: ビスケットの密度のばらつきは、焼成後のサイズや重量に不均一性を生じさせる可能性がある。.

- 変形または反り: ビスケットは型抜き時や乾燥中に反る可能性があり、最終的な寸法に影響を与える。.

- 表面欠陥: ピンホール、気泡、または粗い表面は、釉薬の均一性と装飾品質に影響を与える可能性があります。.

これらの問題を生産の早い段階で対処することは、材料の無駄を最小限に抑え、全体の歩留まりを向上させるために極めて重要です。.

セラミック素地の品質不安定化における一般的な機械的原因

機械設備はビスケットの安定性に極めて重要な役割を果たす。主な原因は以下の通り分類できる:

原料調製装置

安定したビスケットの基礎は適切な 原料準備. よくある問題には以下が含まれます:

- 粒子分布の不均一性: 混合または練り込みが不十分だと粒子サイズが不均一になり、密度に影響を及ぼす。.

- 脱ガス不足: 粘土体内の残留空気は内部の気孔やひび割れの原因となる。.

- 過剰処理: 過度な練り込みや脱気は粘土構造を損ない、成形性に影響を及ぼす可能性があります。.

ユタイ機械ソリューション: 雄大の 高効率真空粘土混練機 均一な混合と完全な脱気を確保し、閉じ込められた空気を除去することで、安定したビスケット成形のための強固な基盤を提供する。.

セラミック成形機

成形段階はビスケットの形状、密度、サイズに直接影響する。一般的な設備の問題点には以下が含まれる:

- 不安定な圧力: 変動する圧力 油圧式 または 等静圧プレス ビスケットの密度が不均一になる原因となる。.

- 摩耗した、または不正確な金型: 低精度の金型は寸法誤差や表面欠陥を引き起こす。.

- 不適切な離型: 型抜きが早すぎたり摩擦が大きすぎたりすると、ビスケットが反ったり割れたりする。.

当社のソリューション: ユタイの精密セラミック成形機 制御可能な圧力システムとカスタマイズ可能な金型圧力プロファイルを備え、均一な密度、一貫した寸法、および成形欠陥の最小化を保証します。.

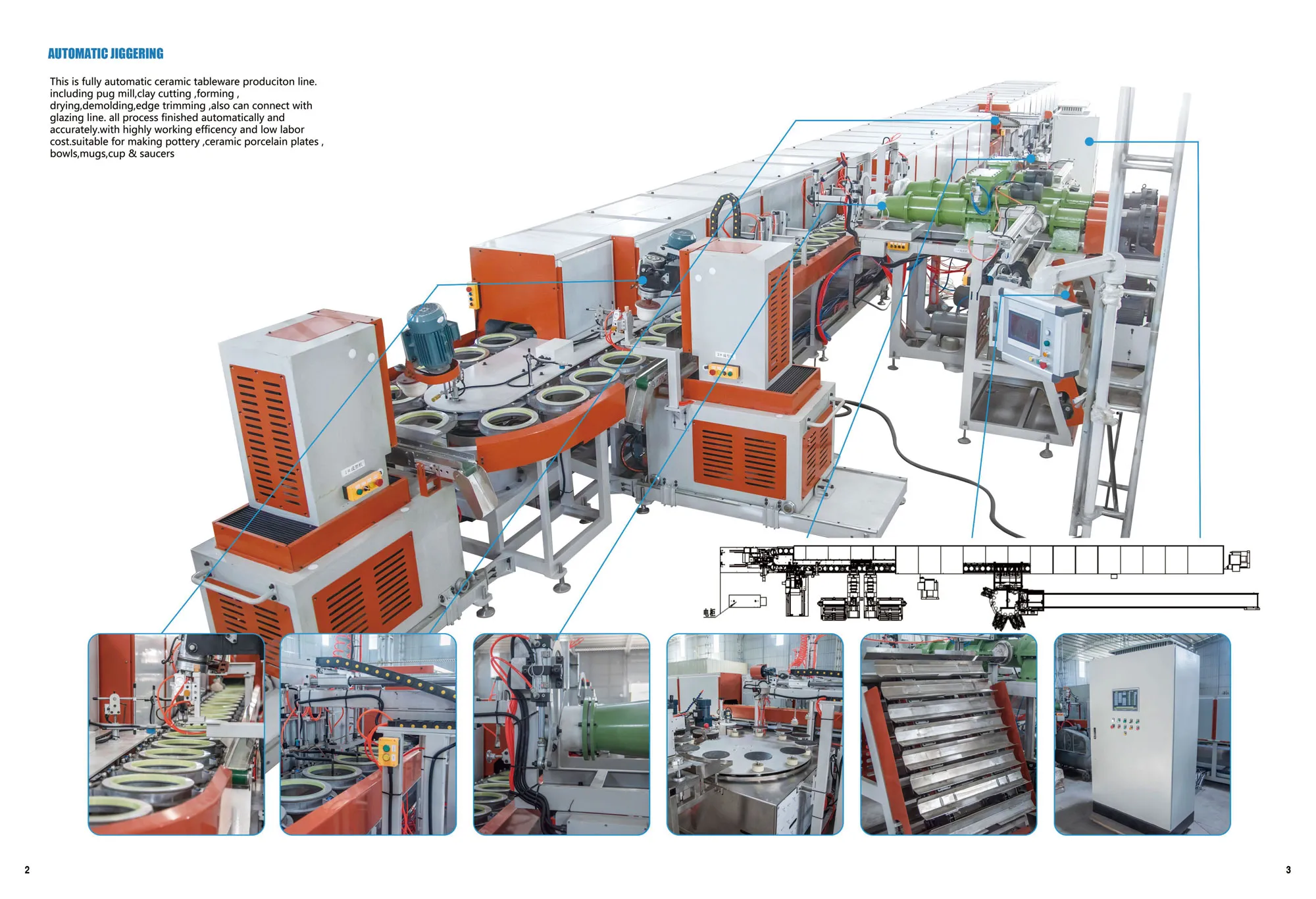

自動化セラミック生産ラインの問題点

一方で 自動化セラミックライン 効率を向上させる一方で、不適切なパラメータ調整や連携不足の作業フローはビスケットの品質に影響を及ぼす可能性があります:

- 変動する射出または成形速度: ばらつきは厚みの不均一を引き起こし、ひび割れのリスクを高める。.

- 給餌位置のずれまたは離型不良: タイミングが不適切だと、反りや縁の変形を引き起こす可能性があります。.

ユタイのソリューション: ユタイは、全工程を同期化する完全統合型自動注入・成形ラインを提供し、様々な製品仕様や生産速度に対応した一貫性のある安定したビスケットを保証します。.

制御システムとパラメータ設定

多くの工場では手作業に大きく依存しているため、重要なパラメータにばらつきが生じている:

- 誤ったPLCまたは制御設定: 圧力、時間、または速度が最適化されていない可能性があり、成形結果に影響を及ぼす。.

- リアルタイム監視の欠如: 異常な状態は、欠陥が発生するまで気づかれないことがある。.

ユタイ機械ソリューション: 雄大の インテリジェント制御システム 成形圧力、射出時間、温度などの重要パラメータをリアルタイムで監視します。履歴データ分析により生産設定を最適化し、人的ミスを削減しビスケットの安定性を維持します。.

解決策と改善策

ビスケットの不安定な形状の機械的要因に対処するため、工場では以下の対策を実施できる:

原料準備の最適化

- 用途 ユタイ高効率真空ニーダー 均一な混合と完全な脱気のため。.

- 定期的なメンテナンスにより、粘土の品質が安定します。.

精密成形装置を採用する

- インストールする ユタイ自動セラミック成形機 安定した圧力制御のため。.

- 製品仕様に基づき金型をカスタマイズし、寸法精度と表面品質を維持する。.

自動化生産ラインを統合する

- 活用する ユタイ自動注入・成形ライン プロセスを同期させる。.

- 生産リズムと圧力曲線を調整し、様々な陶磁器製品に適合させることで、割れ率を低減する。.

インテリジェント監視を導入する

- デプロイ PLCベースのリアルタイム監視システム 主要なパラメータを最適な範囲内に維持する。.

- 過去のデータを活用してプロセスを継続的に最適化し、ビスケットの品質を安定させる。.

事例研究

日用陶磁器工場は、従来の手動注入と油圧プレスシステムをアップグレードした。 雄泰セラミックマシン, 自動注入ラインおよびPLC制御システムと共に。アップグレード後の結果には以下が含まれた:

- ビスケットひび割れ率の50%による低減

- 30%による生産効率の向上

- 表面品質の大幅な向上と材料廃棄物の削減

この事例は、高度な機械的ソリューションがセラミック素焼き品の品質と生産最適化に与える影響を示している。.

結論

安定 素焼きの質 はセラミック生産における中核的な指標であり、 機械設備 中心的な役割を果たす。高性能設備の活用、成形プロセスの改良、自動化と知能制御技術の統合により、工場はビスケットの品質向上、不良率の低減、生産量の増加を実現できる。.

ビスケットの安定性と生産効率を向上させたい場合、, ユタイ 完全に提供する カスタマイズされたセラミック機械ソリューション 原材料の準備から成形、自動化に至るまでの全工程を網羅する。. お問い合わせ カスタマイズされた生産ライン計画と技術サポートを得るために。.