陶磁器食器メーカーにとって、粘土から完成品に至るまでの各工程は、品質と生産能力にとって極めて重要です。陶磁器 自動セラミック生産ライン は、これらの個別のプロセスを効率的な閉ループにつなぎます。自動化されたセラミック生産ラインとは何でしょうか?その中核部品とは何でしょうか?そして、それは企業にどのようなかけがえのない利点をもたらすのでしょうか?この記事では、これらの疑問に答えるべく、詳細な分析を行います。.

自動セラミック生産ラインとは?

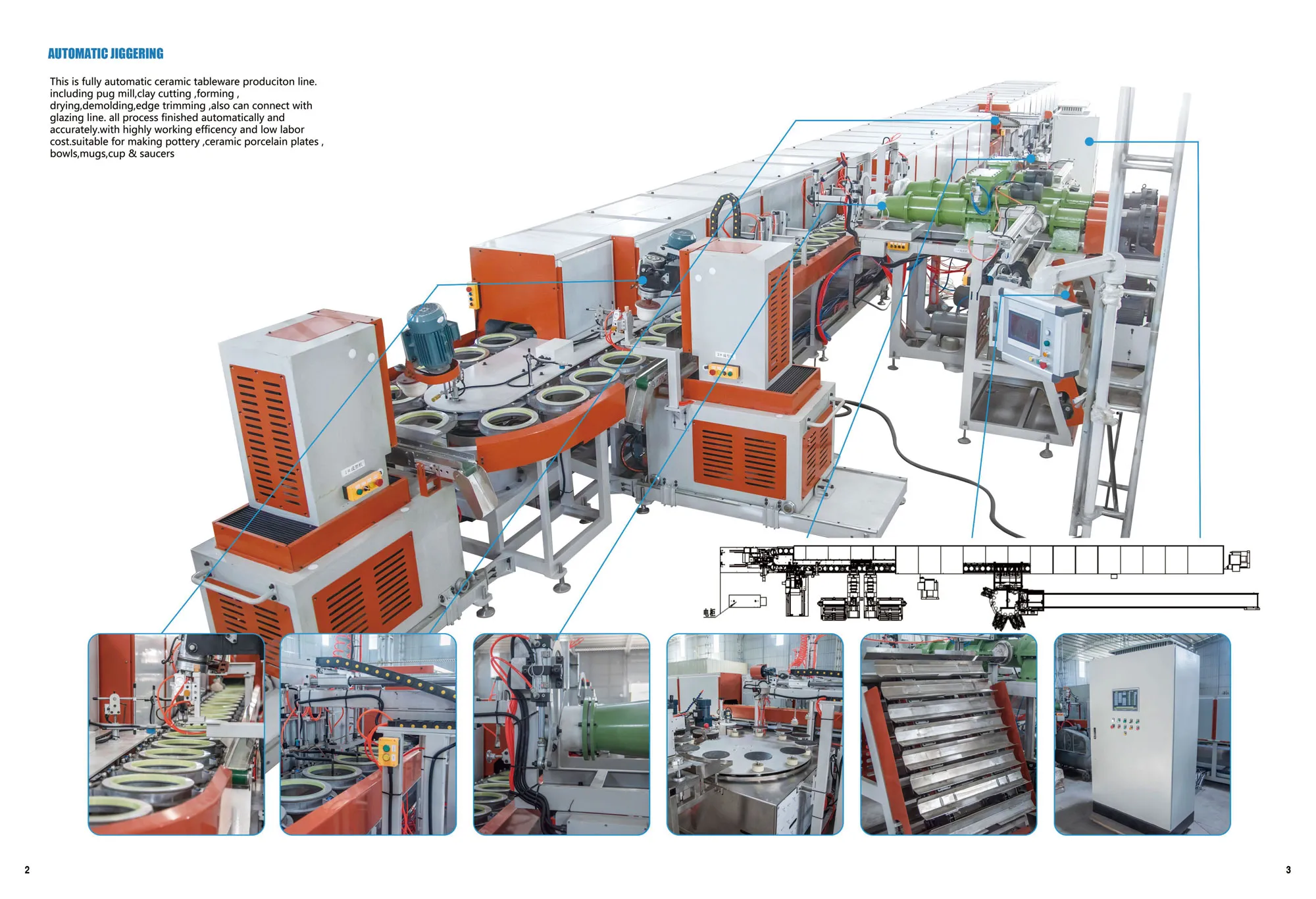

自動化セラミック生産ラインは、一連の機械設備とインテリジェントな制御システムを使用し、セラミック生産における複数の重要な工程を連続的、統合的、かつインテリジェントに生産します。手作業と個々の機械に依存する従来の方法と比べ、自動化生産ラインは次の点を重視しています:

- 効率性:工程間の待ち時間を短縮し、連続運転を実現。.

- 品質:精密な制御による製品の一貫性の向上.

- インテリジェンス: センサーとデータシステムを活用して生産工程を監視し、最適化する。.

現在、自動セラミック生産ラインは、セラミックボウル、洗面器、タイル、アート磁器、工業用セラミックの生産に広く使用されています。.

自動セラミック生産ラインの中核部品

原材料と成形

機能: セラミックボディを自動的に成形し、安定した寸法を確保。.

乾燥

機能: ボディの水分を均一に除去し、乾燥ムラによるひび割れや変形を防ぐ。.

発射

機能:セラミックの密度、強度、耐久性を確保するため、安定した制御可能な高温環境を提供する。.

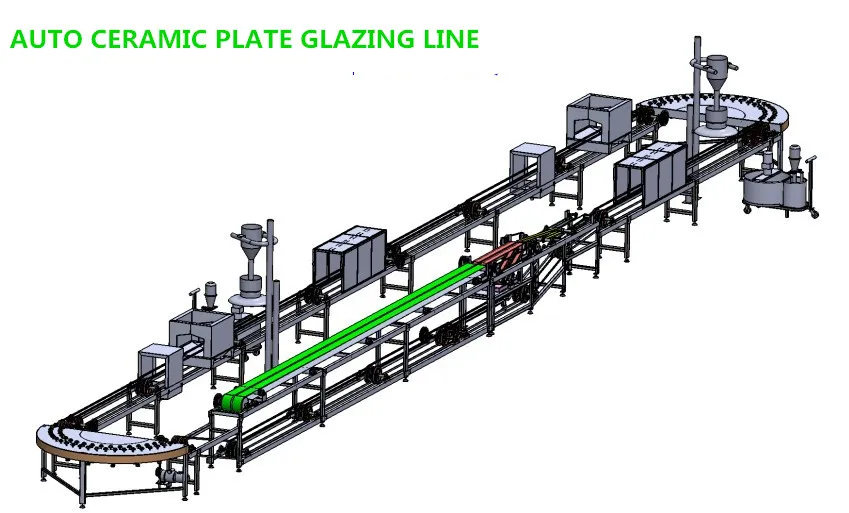

表面処理

機能:均一な釉薬の塗布と装飾パターンを確保し、製品の美観と付加価値を高める。.

仕上げ

機能:完成品の研磨とトリミングを行い、寸法精度と使い心地を保証する。.

補助システム

送電線, インテリジェント・コントロール・プラットフォーム

機能:設備連携とデータ収集が可能になり、生産がよりインテリジェントで透明化される。.

自動セラミック生産ラインの利点

生産効率の向上

自動セラミック製造機はどのように生産効率を向上させるのか? 自動セラミック生産ラインは連続運転を可能にし、生産サイクルを大幅に短縮し、生産能力を大幅に向上させる。.

人件費の削減

自動化された設備は、多数の熟練作業員への依存を減らし、人件費を下げると同時に、人為的ミスによる損失を最小限に抑える。.

製品の一貫性と安定した品質の確保

プロセスパラメーターの精密な制御により、各セラミック製品は高い一貫性と合格率を達成し、不良品率を効果的に低減している。.

省エネと環境保護

自動化された生産ラインは、エネルギーと材料の利用において利点があり、生産コストを削減し、グリーン製造業の発展傾向に沿う。.

インテリジェント&デジタル・アップグレードのサポート

センサーとデータシステムを活用することで、セラミックの自動生産ラインは生産データをリアルタイムで収集し、インテリジェントなモニタリング、プロセスの最適化、予知保全を可能にし、企業がインダストリー4.0に移行するための基盤を築くことができる。.

代表的なアプリケーション・シナリオ

自動セラミック生産ラインの人気が高まるにつれ、その用途は従来の家庭用セラミックにとどまらず、食器、工芸用セラミック、さらには工業用セラミックなど、より幅広い生産ニーズにまで広がっている。.

- セラミック食器:ボウル、皿、洗面器などの日常的な陶磁器を効率的に生産。.

- クラフト・セラミックス:大規模再生産と装飾プロセス制御。.

- 産業用セラミックス:高性能・高精度セラミック製品の生産ニーズに対応。.

結論

エントリー 自動生産ライン セラミックスの世界に、効率、品質、インテリジェンスにおける体系的な改善をもたらしました。生産能力の向上を目指す中規模・大規模工場や、コスト削減と品質の向上を求める企業にとって、自動生産ラインは魅力的な開発選択肢となっています。.

として 大手セラミック機械サプライヤー、Yutai お客様へ ワンストップセラミック製造ソリューション セラミック乾燥機、窯、施釉機から包括的な自動生産ラインソリューションまで、セラミック企業の生産強化と市場機会の把握に貢献します。ようこそ お問い合わせ をクリックして、セラミックス製造ソリューションの詳細をご覧ください!