How to make an oval ceramic plate? It is a concern for many tableware manufacturers. As a professional ceramic tableware machinery supplier, Yutai has always been committed to providing a one-stop ceramic machine solution for global ceramic factories. This article explores the production process of an oval ceramic plate and focuses on the core role of ceramic-forming machines.

Oval ceramic plates production steps

From raw materials to finished products, the production of oval ceramic plates can be roughly divided into the following key steps:

Raw material preparation: Select high-quality porcelain clay, and after batching, mixing, and impurity removal, form ceramic mud with good plasticity.

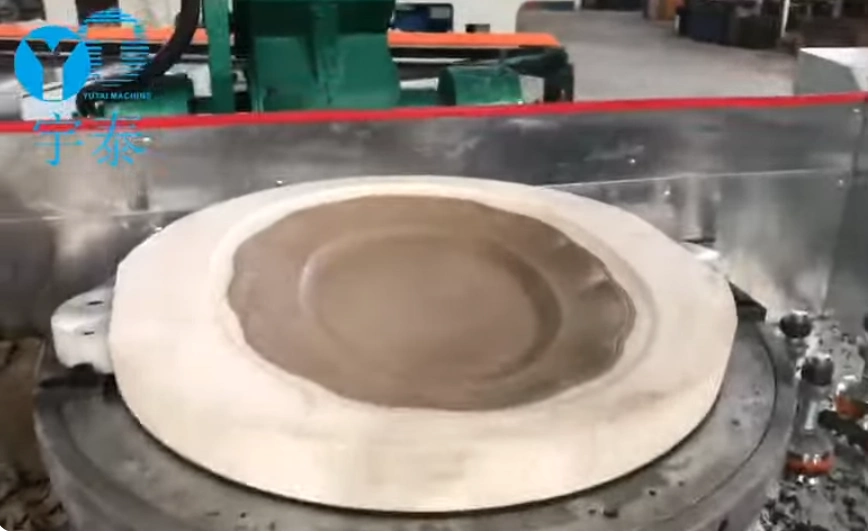

Automatic pressing and molding: This is the most critical step. With Yutai ceramic jigger machine is used to inject the ceramic mud into the mold and form the initial shape of the oval plate by pressing. Our ceramic forming machine has the following advantages:

- Accurately control the amount of mud put in;

- Fast mold molding to increase production;

- The oval shape and size are uniform, with minimal error.

Trimming and drying: After forming, the edge of the plate is trimmed by machine or manual, and the moisture is removed by the drying system or natural drying to avoid deformation.

Firing and glazing: The dried ceramic plate enters the intelligent kiln for high-temperature firing, and then glazes are applied to improve the appearance and practicality.

Secondary firing and testing: The glazed ceramic plate is fired again at high temperatures to ensure that the glaze layer is smooth and uniform, and finally, the defective products are screened by automatic testing equipment.

Ceramic automatic forming machine: an essential machine to improve production efficiency

In the oval ceramic plate production process, the ceramic automatic forming machine independently developed by Yutai helps enterprises improve production efficiency and ensure product quality with its precise, efficient and stable characteristics.

Efficient and automated production

The whole machine operation process is highly automated, and only one employee is needed to complete the loading, pressing and demolding processes. Up to 8-10 products can be formed per minute, far exceeding manual output.

Flexible mold switching, adaptable to a variety of shapes

It supports quick mold replacement and is not only suitable for oval ceramic plates but can also produce other non-circular tableware, such as square plates, special-shaped plates, etc. Provide customers with a wider range of production options and customization capabilities.

Accurate molding parameters, stable and consistent

Equipped with HMI control interface, easy to operate and easy to use, you can set key parameters such as pressing time, pressure, demolding rhythm, etc., effectively guaranteeing the dimensional accuracy and surface finish of each ceramic tableware.

Strong structure, easy maintenance

Yutai ceramic forming machine adopts a thickened steel frame and a high-precision hydraulic system, stable operation and long service life. Daily maintenance is simple to reduce the equipment failure rate.

Why choose Yutai Ceramic Machinery Manufacturer?

As a leading ceramic tableware machinery manufacturer, Yutai Machinery has several advantages:

• Focusing on the field of ceramic equipment for more than ten years, with rich technical experience;

• Providing a to z automation ceramic machine solutions, including automatic molding machines, intelligent kilns, packaging lines, testing equipment, etc.

• Possessing independent research and development capabilities and customized services, supporting customers to customize molds and equipment configurations on demand;

• Timely supporting after-sales service and rapid response to technical support;

• The equipment structure can be customized according to the customer’s production line layout and product type.

• The machines are widely exported to Europe, Southeast Asia, the Middle East, and other places, and are deeply recognized by international customers.

Conclusion

If you are looking for reliable ceramic automation production equipment, especially automatic forming solutions for special shapes such as oval ceramic plates, Yutai Machinery will be your ideal partner. We not only provide high-performance ceramic forming machines but also provide you with continuous technical support and after-sales service so that your production line can truly achieve automation, efficiency and intelligence. Contact us to get your special shape customized ceramic tableware solution.