Economic influence has prompted countries, especially developing countries, to establish local ceramic production facilities. Traditionally traded ceramics have evolved to include increasingly local production to reduce costs and increase profits. As a ceramic machinery manufacturer with over 15 years of experience, we will guide you through this blog to set up a ceramic production plant from scratch.

Understanding the Ceramic Production Process

First of all, you need to have a simple understanding of the production process of ceramics, which is beneficial to your construction of ceramic factories, but also on how to carry out the subsequent trafficking will help. In short, ceramics production is “the manufacture and refinement of clay – the molding and repair of biscuit – the glaze of biscuit – the firing of biscuit – finished“. These several stages are combined in a process, and each stage is subdivided under the manufacture of different ceramics require different things. Therefore, defining your production target range is something you need to determine initially. (The following is an automatic ceramic production line how to complete the ceramic production video)

Scaling Ceramic Production

When scaling production, manufacturers must consider several factors:

- Capacity planning: Evaluate the demand forecasts and determine the capacity needed in terms of production volume.

- Initial capital arrangement: Comprehensive budget and reasonable allocation of funds, ensure a stable and reliable source of funds, improve the efficiency of use, strengthen supervision, fully consider risks, and formulate a return plan of funds

- Location considerations: Choose a location that optimizes access to raw materials and markets. Consider local labor markets, transportation logistics, energy supply, and regulatory environment.

- Raw material supply: It is necessary to assess whether the country or adjacent areas have established sources of clay, taking into account the price of raw materials. Choosing a location close to where raw materials are produced or with a well-established supply chain will help reduce raw material costs.

- National and local policies: When building a ceramic factory, local laws, regulations, and policies should be complied with, such as land planning, environmental protection policies, labor laws, and regulations.

- Layout design: The layout of the facility should promote an efficient flow of materials. It is essential to plan for separate zones for raw material storage, production lines, firing kilns, and shipping areas.

- Efficiency upgrades: Automate processes where possible to increase production speed and consistency.

- Quality control: Implement stringent quality control measures to ensure that increased production does not compromise product quality.

Planning a Ceramic Manufacturing Facility

Investing in the right equipment is vital for operational success. I will explain in detail all the equipment needed in the production process and its role.

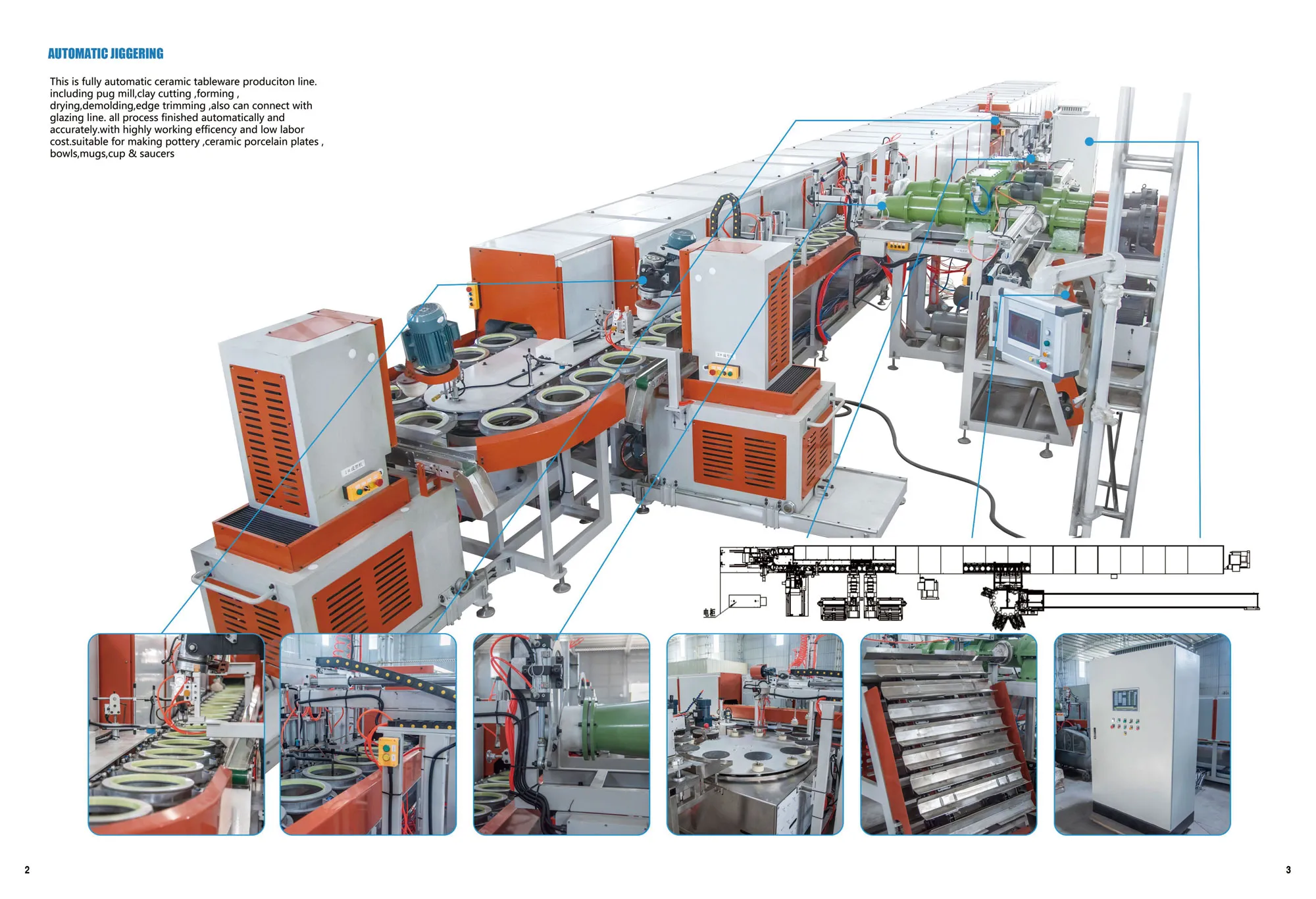

Automatic ceramic forming equipment

For high-volume production, automated forming machines can drastically reduce labor costs and improve consistency. A large-scale ceramic production plant requires a large site or several high-rise buildings, with large and fully automated ceramic production machinery for production. A small to medium-sized ceramics factory does not require such conditions and can only use semi-automated machinery or labor to achieve the goal.

Different ceramic equipment for each production step

Clay making machines: ball mills, vibrating sieves, iron removers, piston pumps, filter presses, plug mills, and clay cutting machines.

How the making clay machines work:

First, a ball mill is used to finely grind the raw sand and a vibrating sieve removes larger particles. Then, through the iron removal machine, removal of iron impurities it. The treated sludge is placed in a deep tank to separate the water from the sludge. After the separation is completed, the mud is compressed by a filter press to form a dense mud cake. Then it is further processed by the plug mill and converted into long strips of mud. Finally, through a precise clay-cutting machine operation, we cut the mud strips into evenly sized mud cakes. These elaborately molded cakes are the clay, a key raw material used in ceramic production.

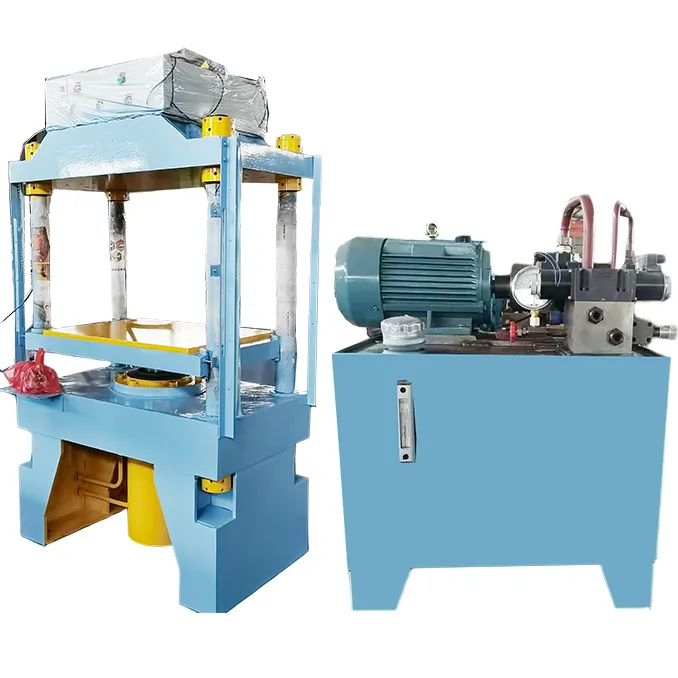

Clay forming machine: ceramic press machine, semi-auto jigger machine, fully-auto jiggering machine, slip casting machine

How the clay forming machines work:

In general, most of the ceramics are produced through the jiggering machine, just put the mud into the ceramic mold and start the machine, to be rolled to the head of the ceramic mud pressed into shape after taking out and dried.

Semi-auto jigger machine only rolls this step, the output is small and requires workers to uninterruptedly dismantle and change the mold. The fully-auto jiggering machine contains the practice of clay, cutting, rolling, drying, and other links, only in a fixed period to fill the new strip of clay, eliminating the dismantling and changing of molds and drying time, and also saving the links of manpower, so the output is higher and the output is more stable.

In addition, there is another production method for all kinds of shaped ceramic ware and all kinds of ceramics including handles, which is called slip casting machine. Grouting is the process of injecting slurry directly into a closed mold, and then removing the mold after it has stood still to take out the molded ceramics, which is mostly used in the production of toilets.

In this, slip-casting machines and semi-automatic machines are cheaper, while fully automatic slip-casting machines and rolling machines are more expensive, you need to choose the machine according to their needs.

Glazing machine: automatic ceramic glazing machine, glaze dipping machine, glaze spray booth, glaze wiping machine

Kilns: Select kilns that suit your specific product needs—shuttle kilns, tunnel kilns, roller kilns, small ceramic kilns

In Conclusion

Well, after my introduction to this series, I believe you have the ceramic production process and the various stages of the machine required to have an understanding of the hope that you can also be a reasonable assessment of their situation, there are any questions you can also through our official website https://yutaimachinery.com/, email and contact with us, we help to realize the customer from the ground up to establish a ceramic production plant belonging to the customer. Thank you very much for reading my article, I wish you a good day.