Automatisation est devenu un facteur essentiel dans les usines pour améliorer l'efficacité de la production, garantir une qualité stable des produits et réduire les coûts de main-d'œuvre. En tant que Yutai, fabricant leader de machines pour la céramique se concentre sur le solution globale pour la production automatisée de céramique, allant de machines de formage de la céramique à systèmes de vitrage en céramique, séchoirset fours à céramique. Les fabricants de céramique doivent comprendre les tendances mondiales en matière d'automatisation des usines de céramique et les différences entre les demandes des différents pays s'ils souhaitent se développer à l'international ou optimiser leurs chaînes de production.

Pourquoi Automatisation Questions relatives à Fabrication de céramiques

Automatisation dans la fabrication de céramiques confère plusieurs avantages importants :

- Il améliore considérablement l'efficacité de la production, permettant ainsi aux usines de traiter des commandes importantes sans compromettre la qualité. Les dimensions des produits, l'application de la glaçure et les résultats de la cuisson sont uniformes grâce aux systèmes automatisés.

- L'automatisation réduit la dépendance à la main-d'œuvre, diminuant ainsi les erreurs humaines susceptibles d'entraîner des défauts liés à un émaillage irrégulier, des fissures ou des déformations.

- Les systèmes automatisés modernes facilitent considérablement l'intégration des différentes étapes de la production céramique (formage, émaillage, séchage, cuisson, etc.), rendant ainsi la chaîne de production céramique beaucoup plus intégrée et fluide.

De nos jours, une usine qui souhaite rester compétitive doit d'abord mettre en œuvre machines automatiques, qui devrait répondre aux besoins de production actuels tout en pouvant être étendu à l'avenir. C'est là que Yutai se distingue particulièrement, en apportant une valeur ajoutée grâce à sa qualité, sa fiabilité et sa personnalisation pour une grande variété d'applications.

Différences en matière de demande d'automatisation sur les marchés mondiaux

Chine

Plusieurs usines de céramique de taille moyenne et grande en Chine approvisionnent les marchés nationaux et internationaux en vaisselle et en articles sanitaires. En Chine, l'automatisation vise principalement la production en série et à grand volume. En général, les usines s'intéressent aux machines qui permettent d'obtenir un rendement plus élevé avec des taux de défauts plus faibles, comme les machine de formage automatisée, machine de pulvérisation de glaçureet fours à céramique. Les fabricants chinois trouvent généralement un équilibre entre le coût et l'efficacité de la production lorsqu'ils choisissent des équipements automatisés.

Europe

Les marchés européens de la céramique se concentrent sur la production en petites séries et à forte valeur ajoutée, comme la céramique d'art et la vaisselle design. L'automatisation dans cette région met l'accent sur la précision, la flexibilité et l'efficacité énergétique. Les usines ont besoin de machines capables de traiter des formes complexes et des glaçures délicates tout en garantissant le respect des normes environnementales et de sécurité. Solutions pour machines céramiques Les produits les plus appréciés sont ceux qui sont personnalisables et faciles à entretenir.

Amérique du Nord

En Amérique du Nord, les fabricants de céramique accordent la priorité absolue aux lignes de production standardisées et entièrement intégrées. L'automatisation est conçue pour offrir évolutivité, contrôle des processus et traçabilité. Les acheteurs recherchent des machines qui relient les processus de formage, émaillage, séchage et cuisson en résultats cohérents et reproductibles, garantissant un rendement constant. Tout aussi importants sont un service après-vente performant, la disponibilité des pièces de rechange et la fiabilité à long terme.

Asie du Sud-Est et marchés émergents

L'adoption de l'automatisation est très inégale en Asie du Sud-Est et dans la plupart des marchés émergents, où de nombreuses petites usines restent compétitives à l'échelle internationale en utilisant des processus entièrement manuels. Il s'agit d'une tendance à l'automatisation progressive. Les machines doivent être abordables, simples à utiliser et robustes pour que les petits fabricants puissent bénéficier de gains d'efficacité avec un minimum d'exigences techniques.

Clé Tendances en matière d'automatisation dans le monde Industrie céramique

- Les grands producteurs investissent dans des lignes entièrement automatisées afin de gagner en efficacité et de réduire les coûts de main-d'œuvre.

- Les marchés de la céramique artistique ou à forte valeur ajoutée privilégient les machines flexibles et précises.

- L'intégration du formage, du vitrage, du séchage et de la cuisson dans une chaîne de production automatisée et fluide est de plus en plus courante.

- L'efficacité énergétique, la faible maintenance et la facilité d'utilisation sont des caractéristiques appréciées de tous.

Comprendre ces tendances aide les fabricants de céramique à prendre des décisions éclairées quant aux solutions d'automatisation les mieux adaptées à leurs objectifs de production et à leurs marchés cibles.

Comment Yutai Machinery Prend en charge Global Besoins en automatisation

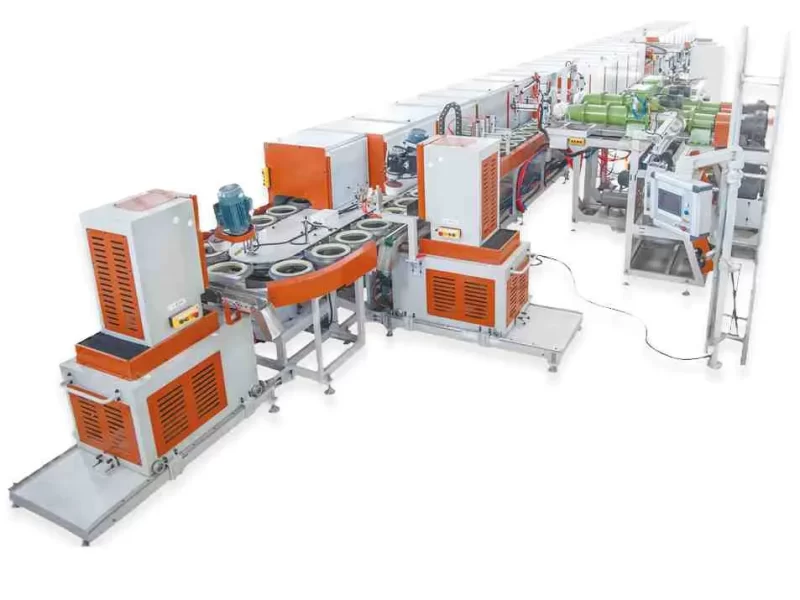

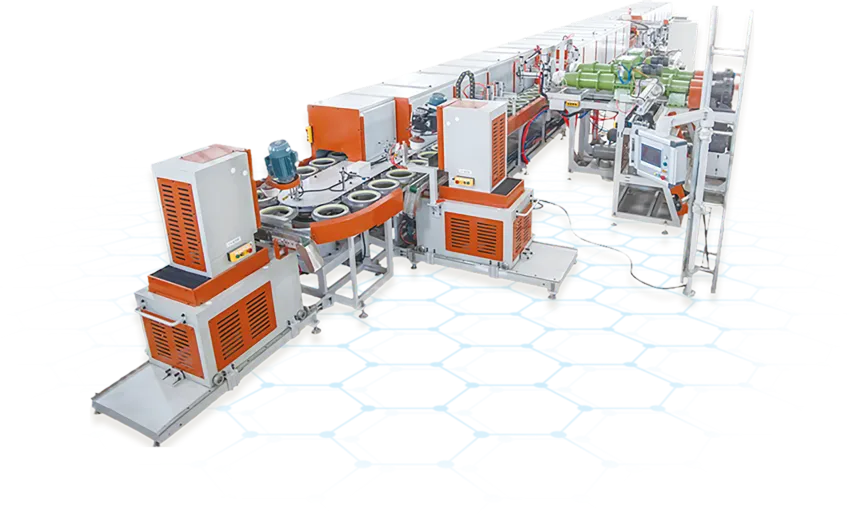

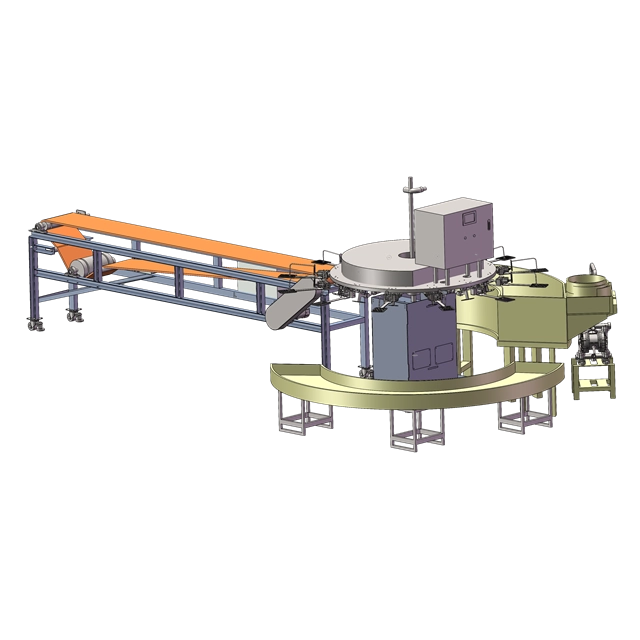

En tant que fabricant professionnel de machines à céramique, Yutai fournit des solutions d'automatisation de bout en bout adaptées aux différentes exigences du marché et aux besoins de production. Notre gamme d'équipements comprend :

- Machines de formage automatiques et semi-automatiques pour bols, assiettes, tasses et articles sanitaires.

- Systèmes de glaçage capables de traiter des glaçures à haute viscosité et riches en pigments pour une qualité de surface constante.

- Séchoirs optimisés pour une élimination uniforme de l'humidité et un débit élevé.

- Fours conçus pour être écoénergétiques et permettre un contrôle précis de la température.

Yutai fournit des solutions entièrement personnalisables pour une grande variété de types de produits, d'échelles de production et de besoins régionaux. Grâce à ses services après-vente dans le monde entier, les usines peuvent réduire efficacement les temps d'arrêt dans leurs opérations mondiales.

Conclusion

Dans le monde concurrentiel actuel de la céramique, l'automatisation n'est plus une option, mais une nécessité. Les solutions d'automatisation sont de plus en plus mises en œuvre par les usines du monde entier afin de réduire les goulots d'étranglement dans la production, de garantir la qualité des produits et de minimiser la dépendance à la main-d'œuvre. Les besoins en matière d'automatisation varient : les producteurs à grand volume visent la rapidité et la répétabilité, tandis que la flexibilité, la précision et la personnalisation sont les maîtres mots des marchés à forte valeur ajoutée. Yutai, un fabricant fiable de machines pour la céramique, fournit des solutions fiables, évolutives et compatibles à l'échelle mondiale, permettant à tout fabricant de mettre en œuvre en toute confiance des lignes de production automatisées. Qu'il s'agisse de moderniser une ligne existante ou de planifier une nouvelle usine,nous contacter aujourd'hui pour explorer solutions personnalisées de machines automatisées pour la céramique et améliorer l'efficacité dans la production de céramique.