Dans le processus de production de la céramique, le fonctionnement efficace des machines est la clé du bon fonctionnement de la ligne de production. Les défaillances des machines céramiques peuvent affecter la productivité et entraîner des coûts de maintenance élevés. En tant que fabricant leader de machines à céramique, Yutai triera systématiquement les Guide des défaillances courantes et des solutions pour les machines céramiques basé sur l'expérience de production réelle pour vous aider à obtenir un fonctionnement efficace de votre équipement.

Défaillances courantes des machines céramiques et solutions

La machine de moulage automatique fonctionne anormalement

Performance : Le moule bouge mal, la précision du formage diminue et le pressage n'est pas en place.

Raisons courantes :

- Manque de lubrification ou blocage de la piste du moule par un corps étranger.

- Vieillissement des joints du système hydraulique ou température anormale de l'huile.

- Le retour d'information du capteur de déplacement n'est pas précis.

Solution :

- Remplir d'huile lubrifiante et nettoyer la zone de mouvement du moule.

- Remplacer les joints vieillissants et changer régulièrement l'huile hydraulique pour contrôler la température de l'huile.

- Réglez ou remplacez le capteur de position pour garantir un retour de signal précis.

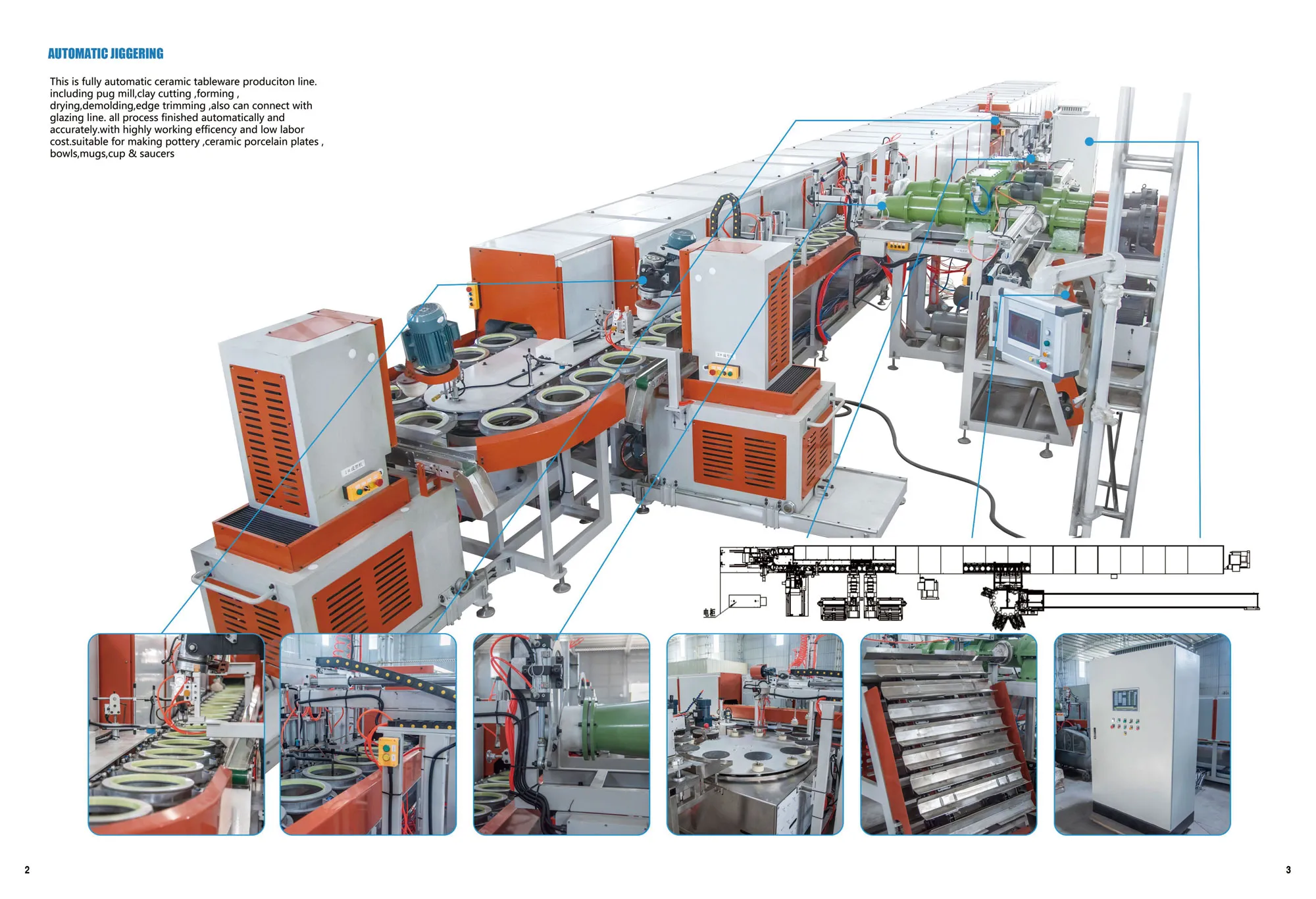

Avantage de la machine Yutai : Le machine automatique de formage de céramique adopte un rail de guidage de haute précision et une structure autolubrifiante pour réduire l'usure des rails, et est équipé d'un système hydraulique stable et d'un capteur de déplacement à haute sensibilité pour garantir que l'action du moule est rapide, précise et ne se bloque pas.

Le contrôle de la température du four à céramique est instable.

Performance : La qualité des produits cuits est très variable : brûlure, noircissement, etc.

Raisons courantes :

- Le thermocouple est endommagé ou mal disposé.

- Les paramètres de réglage du système de contrôle de la température sont anormaux.

- La couche isolante du four vieillit et le carbone se dépose dans le four.

Solution :

- Remplacer le thermocouple endommagé et recalibrer la position et la hauteur.

- Vérifier et optimiser la logique du programme de contrôle de la température pour s'assurer qu'elle correspond à la courbe de cuisson du produit.

- Nettoyez régulièrement les dépôts de carbone dans le four et remplacez les matériaux d'isolation vieillissants pour améliorer l'efficacité thermique.

Solution de machine Yutai : La Four à céramique de Yutai est équipé d'un système efficace de dissipation de la chaleur et d'un système précis de contrôle de la température, qui permet de maintenir la température de fonctionnement normale de l'équipement en fonctionnement automatique et d'éviter la surchauffe.

Les équipements de détection automatique se trompent fréquemment et identifient de manière imprécise.

Performance : Faux positifs ou défauts manqués, alarme visuelle du système

Causes courantes :

- Accumulation de poussière sur l'objectif ou déséquilibre de la source lumineuse.

- L'algorithme de vision n'est pas adapté au nouveau produit.

- Les signaux parasites externes affectent la précision de la reconnaissance.

Solution :

- Essuyez régulièrement l'objectif pour vous assurer que l'image est claire ; réglez l'éclairage pour éviter les interférences avec les ombres.

- Mise à jour des procédures d'inspection visuelle pour les adapter aux différentes formes ou couleurs de la vaisselle.

- Optimisez l'environnement de travail pour éviter les reflets, les vibrations ou les interférences dues à l'éblouissement extérieur.

Application de l'équipement Yutai : L'équipement d'inspection de Yutai adopte un système de vision de qualité industrielle, qui offre une compatibilité et une précision de reconnaissance accrues pour diverses formes de céramiques et surfaces de fleurs, et réduit le taux de faux positifs.

Bruit anormal et gigue de fonctionnement du moteur ou du système de transmission

Performance : Glissement de la chaîne, bruit du moteur, fonctionnement instable.

Causes courantes :

- Le jeu de la courroie ou l'usure de l'engrenage.

- Manque d'huile ou usure importante des roulements du moteur.

- Le tendeur est défaillant.

Solution :

- Régler la tension des chaînes et des courroies et remplacer les courroies ou les engrenages si nécessaire.

- Ajoutez de l'huile lubrifiante ou remplacez les roulements endommagés pour éviter que l'augmentation de température du moteur ne soit trop importante.

- Réviser le mécanisme de tension pour s'assurer que les composants de la transmission sont toujours en bon état d'engrènement.

Yutai Machinery Equipment Points forts : Machines à céramique Yutai Le système d'entraînement principal adopte des moteurs importés de haute qualité et des structures d'engrenage épaissies, ce qui permet de réduire efficacement les dommages soudains.

Comment la maintenance permet-elle d'éviter les pannes d'équipement ?

La maintenance préventive est essentielle pour garantir le fonctionnement stable à long terme des équipements céramiques. La machine à céramique fournie par Yutai possède un degré élevé d'automatisation, ce qui lui permet d'effectuer une surveillance automatique et un diagnostic en temps réel. Vous pouvez réduire efficacement l'incidence des pannes d'équipement en prenant les mesures suivantes :

Inspection régulière : Inspecter régulièrement les différents systèmes de l'équipement afin de détecter à temps les défaillances potentielles.

Nettoyer l'équipement : Maintenez l'équipement propre, en particulier le système de dissipation de la chaleur, afin d'éviter que la poussière et la saleté n'affectent le fonctionnement normal de l'équipement.

Lubrification régulière : De l'huile de lubrification est régulièrement ajoutée à toutes les pièces de l'équipement pour réduire les frottements et prolonger la durée de vie.

Mise à jour du logiciel : Pour les équipements d'automatisation, mettez régulièrement à jour les versions des logiciels et des microprogrammes afin de garantir l'efficacité opérationnelle de l'équipement.

Formation des opérateurs : Fournir une formation technique aux opérateurs de première ligne pour les aider à maîtriser les techniques d'inspection de base et les capacités d'identification des anomalies.

Gestion des stocks de pièces détachées : Les thermocouples, les électrovannes, les capteurs, les joints et autres consommables courants sont toujours disponibles pour assurer un remplacement rapide.

Pourquoi choisir Yutai Machinery ?

Équipement à haut degré d'automatisation: Nos équipements atteignent un haut degré d'automatisation, réduisent le travail manuel et améliorent la productivité.

Machines à haut rendement: Nos machines utilisent les technologies les plus récentes pour faciliter une production efficace, l'économie d'énergie et la protection de l'environnement.

Un service après-vente optimal: Fournir une assistance complète telle que l'installation et le démarrage des équipements, la formation et la maintenance.

En tant que marque de premier plan dans l'industrie des machines à céramique, Yutai ne se contente pas d'offrir un excellent équipement, mais propose également à ses clients une assistance technique complète et un service après-vente. Notre personnel proposera des solutions personnalisées de maintenance des équipements en fonction des exigences uniques des clients afin de garantir la stabilité de la chaîne de production..

conclusion

En éliminant et en entretenant les défaillances fréquentes de l'équipement, vous pouvez optimiser l'efficacité de la ligne de production de céramique et prolonger la durée de vie de l'équipement. Yutai s'efforce d'offrir aux usines de céramique du monde entier des solutions efficaces, intelligentes et pratiques pour les machines à céramique qui permettent aux clients d'améliorer l'efficacité globale. Si vous souhaitez en savoir plus sur les paramètres de l'équipement et les services de maintenance, veuillez cliquer sur le lien suivant nous contacter.