With the development of the global ceramic production industry toward automation, large-scale manufacturing, and high-value-added production, expectations for ceramic machinery suppliers continue to rise. Customers now require not only reliable equipment, but also integrated production solutions, predictable delivery, and long-term technical support. In response to these evolving market needs, Yutai relocated to a new ceramic machinery facility at the beginning of 2026. This strategic move represents more than a simple change of address—it marks a comprehensive upgrade in manufacturing capacity, system integration, and turnkey project execution. With the new facility, Yutai is better positioned to deliver higher-quality, consistent, and customized ceramic machines for ceramic manufacturers worldwide, with improved efficiency.

A Key Milestone in Yutai’s Development

Yutai, a professional ceramic machinery manufacturer, specializes in high-quality ceramic machinery solutions. Over the years, Yutai has served customers across a wide range of ceramic sectors, including tableware, sanitary ware, ceramic planters, mugs, and industrial ceramics.

As overseas projects increase in scale and complexity, and demand for customized solutions continues to grow, Yutai has consistently invested in strengthening its manufacturing and service capabilities. The launch of the new facility is a natural and strategic step to support long-term growth and evolving global customer needs, further reinforcing Yutai’s position as a reliable ceramic machinery partner.

Why Does Yutai Decide to Move to a New Facility?

In recent years, several clear trends have emerged in the global ceramic manufacturing market:

- Growth of new ceramic factories in emerging markets

- Accelerated automation upgrades in traditional ceramic plants

- A shift from single-machine purchases to complete production line solutions

- Higher expectations for delivery reliability, system compatibility, and after-sales support

These changes require ceramic machinery manufacturers to move beyond individual equipment supply and develop system-level manufacturing, engineering integration, and scalable delivery capabilities. Yutai’s new facility was specifically designed to support this next stage of customer demand.

How does the New Facility Enhance Ceramic Machinery Manufacturing?

Optimized Production Space and Workflow

The new facility is planned around the concept of complete production line manufacturing and delivery, with clearly defined areas for:

- Precision machining

- Equipment assembly

- Automation and control system integration

- Full-line testing and trial operation

This optimized layout allows Yutai to operate multiple ceramic production line projects in parallel, improving overall efficiency and delivery coordination for international customers.

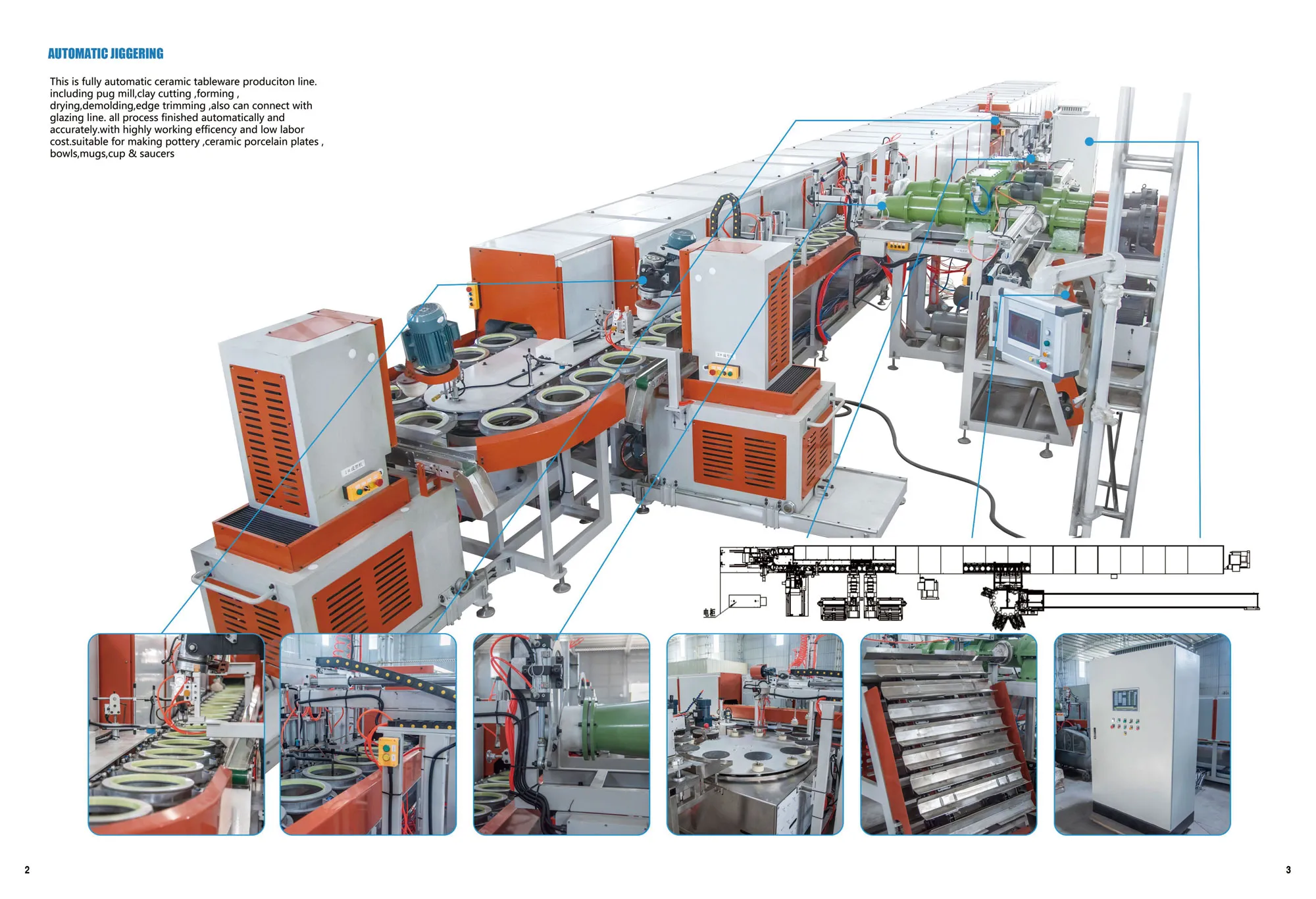

Full Coverage of the Ceramic Production Process

With expanded capacity, Yutai now provides stable manufacturing and integration of equipment covering the entire ceramic production process, including:

- Raw material preparation and clay-making machines

- Ceramic forming machines (pressing, slip casting, jiggering, automatic forming lines)

- Automatic ceramic drying systems

- Machines à émailler la céramique

- Ceramic kilns (roller kilns, tunnel kilns, shuttle kilns)

- Ceramic printing machines (screen printing, pad printing, decal application)

- Finishing equipment, such as ceramic bottom grinding machines

Unified manufacturing and system integration ensure consistency, compatibility, and stable performance across the entire ceramic production line.

Direct Benefits for Global Ceramic Manufacturers

More Reliable Project Delivery

The new facility enables Yutai to manage large-scale orders and turnkey projects more efficiently, ensuring stable delivery schedules even for complex overseas factory projects.

Improved Quality Consistency

Complete production lines can be assembled, integrated, and tested before shipment. This reduces on-site installation risks and helps customers achieve stable production more quickly after commissioning.

Greater Flexibility in Customization

Whether customers require different product types, production capacities, or automation levels, Yutai can now offer more flexible and in-depth customization based on specific project requirements.

Upgraded Custom Turnkey Solutions Capability

From Equipment Supplier to Total Factory Solution Provider

With the new facility, Yutai further strengthens its turnkey ceramic project support, including:

- Factory layout planning

- Process design and equipment selection

- Automation and PLC control system integration

Stronger Support for Turnkey Projects

Entire ceramic production lines can be pre-assembled, integrated, and tested in-house to simulate real production conditions. This significantly reduces risks during overseas installation and commissioning.

Suitable for Multiple Project Types

- New ceramic factory construction

- Automation upgrades of existing plants

- Overseas investment and EPC ceramic projects

Looking Ahead: Long-Term Commitment to Global Customers

The new facility is a key part of Yutai’s long-term development strategy. Moving forward, Yutai will continue to:

- Invest in automation and intelligent control technologies

- Enhance system-level integration and production line coordination

- Strengthen technical support for international markets

- Build long-term, stable partnerships with ceramic manufacturers worldwide

Conclusion: A New Facility, A New Stage, A Stronger Commitment

The move to the new factory represents a comprehensive expansion of Yutai’s production scale, quality control capabilities, and customized turnkey solutions. It enables Yutai to serve ceramic manufacturers with greater efficiency, reliability, and technical integration. Yutai looks forward to working with customers worldwide to build cost-effective, energy-efficient, and future-ready ceramic production lines.