En el campo de la fabricación de cerámica, la eficiencia y la precisión son las tendencias del desarrollo de maquinaria moderna. Línea automática de productos cerámicos avanzados de Yutai Machinery está diseñado para mejorar la eficacia de la producción de platos y cuencos de cerámica. Este equipo de vanguardia integra procesos clave -preparación de la arcilla, moldeado, secado, desmoldeo y pulido de bordes- en una operación sin fisuras, mejorando la productividad y la calidad del producto.

Cómo hacer platos de cerámica cuencos por auto línea de productos de cerámica

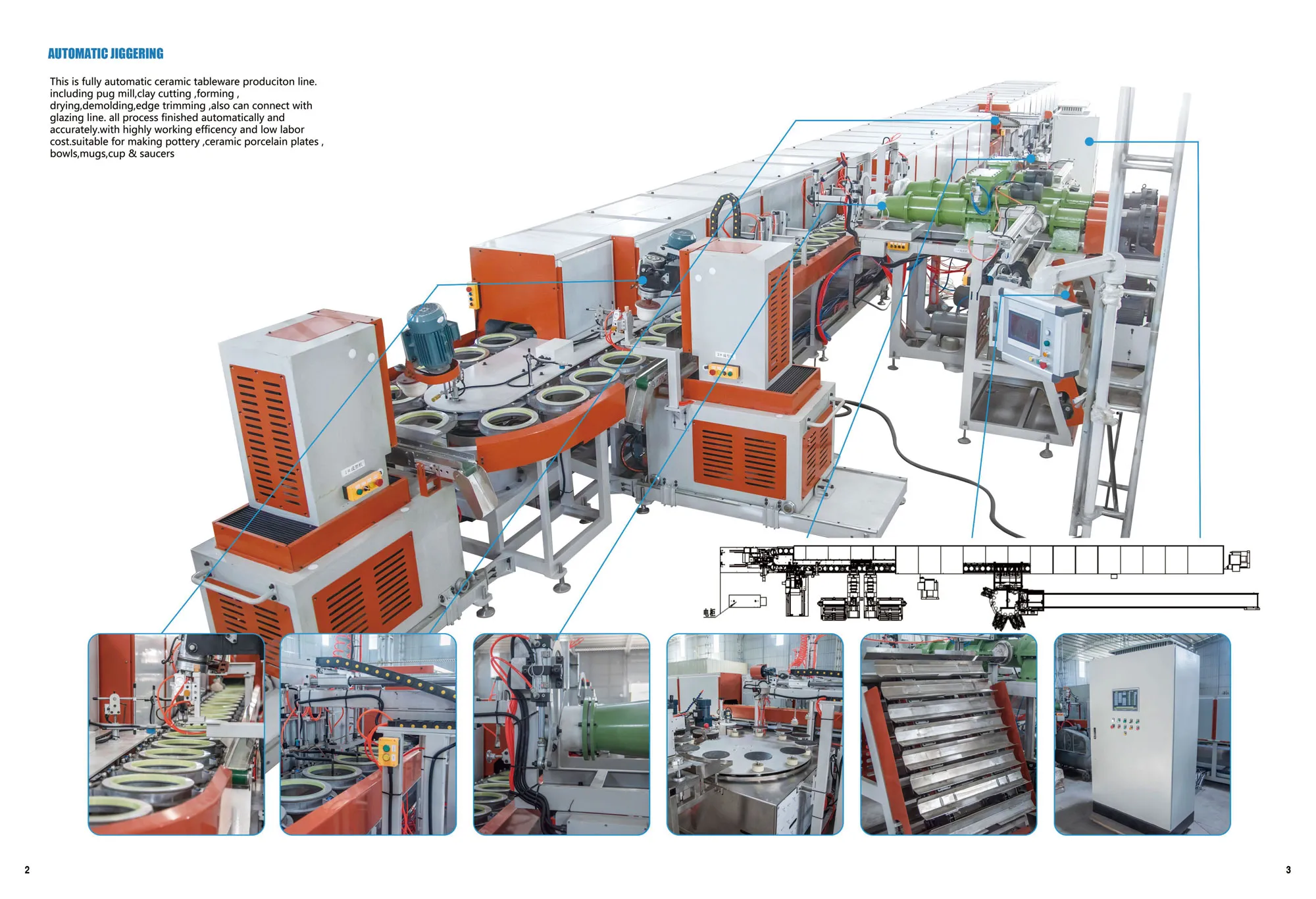

1.Preparación de la arcilla: La arcilla se coloca en un estante, y el estante alimenta automáticamente la arcilla en un entrenador de arcilla de vacío de acero inoxidable 304, que comprime y refina la arcilla en condiciones de vacío para garantizar la trabajabilidad de la arcilla y reducir las burbujas.

2. Moldeo automático por laminación: La arcilla preparada se introduce en la línea de moldeo y se enrolla en forma de disco o cuenco mediante cabezales dobles en el molde.

3. Secado y desmoldeo: El producto pasa por un sistema de tuberías de secado para eliminar gradualmente la humedad y evitar que se agriete y deforme.

4. Desmoldeo: El sistema automatizado extrae cuidadosamente el producto moldeado del molde y lo coloca en la recortadora.

5. Procesamiento de bordes: Máquina recortadora automática multiestación con cizallas recortadoras giratorias para alisar los bordes de los productos, garantizar la uniformidad y mejorar la estética.

Aplicaciones de la línea automática de productos cerámicos

Las líneas automáticas de productos cerámicos de Yutai están diseñadas para satisfacer una amplia gama de necesidades de producción cerámica:

Fabricación de vajillas: Producción eficaz de platos y cuencos con calidad estable.

Cerámica decorativa: Moldeo de precisión para lograr diseños y patrones complejos.

Cerámica industrial: Cumplen los estrictos requisitos de las aplicaciones técnicas e industriales.

Ventajas de la línea automática de productos cerámicos

La tecnología de automatización mejora la eficacia y reduce los costes laborales

Calidad estable: Gracias a la avanzada tecnología de moldeo y a los procesos automáticos de recorte y acabado, se pueden fabricar productos cerámicos precisos y uniformes.

Versatilidad: La línea de moldeo puede producir una gran variedad de productos cerámicos, como platos, cuencos, tazas, etc. Esta versatilidad permite a los fabricantes alternar entre distintas líneas de productos.

Flexibilidad: Los moldes pueden personalizarse para satisfacer requisitos de diseño específicos, con lo que se obtienen productos cerámicos únicos y complejos.

Interfaz fácil de usar: Sistema de control PLC fácil de operar, conveniente para que los operadores controlen y supervisen el proceso de producción.

Soluciones integrales para fábricas de maquinaria cerámica

Yutai Maquinaria Cerámica Proporciona Solución integral para fábricas de maquinaria cerámica:

Instalación y formación: Orientación experta, integración perfecta en las operaciones existentes.

Mantenimiento y asistencia: asistencia continua para optimizar el rendimiento y la vida útil de los equipos.

Conclusión

Aumente su capacidad de producción de cerámica con YUTAIlíneas automatizadas de conformado de cerámica. Combinando tecnología innovadora con un sólido diseño de ingeniería, ayudamos a los fabricantes a lograr la eficiencia en la producción y la excelencia del producto. Póngase en contacto con nosotros hoy mismo para obtener más información sobre las líneas automatizadas de conformado de cerámica y explorar el futuro de la fabricación de cerámica!.