En el proceso de producción de las tazas de té de cerámica, el proceso de impresión no sólo afecta a la claridad y durabilidad del dibujo, sino que determina directamente la belleza y competitividad en el mercado de la taza de té. Como fabricante líder de maquinaria para vajillas de cerámicaYutai se compromete a ofrecer a sus clientes un servicio eficaz, preciso e inteligente. soluciones de impresión cerámica. Hoy tomaremos como ejemplo la impresión de tazas de té de cerámica para ofrecerle un conocimiento profundo de todo el proceso de producción de la impresión y la aplicación de los equipos.

Proceso de impresión de tazas de té

Ajustes de impresión: preparación precisa del patrón

El primer paso en la impresión de tazas de té es establecer el patrón. Este enlace incluye principalmente:

- Selección de plantillas y impresora de tampón cerámico Ajuste de parámetros, como la presión de impresión, el ángulo del rascador, la viscosidad de la tinta, etc.

- Instale y calibre el cabezal de impresión serigráfica o tampográfica para asegurarse de que la posición del patrón coincide exactamente con las especificaciones de la taza de té.

Con Yutai impresora de tampón cerámicoEl proceso de ajuste está muy automatizado y los parámetros pueden ajustarse rápidamente en función de los distintos productos, lo que mejora enormemente la flexibilidad y la eficacia de la producción.

Posicionamiento de la taza de té: garantía básica precisa y correcta

Antes de la impresión formal, la taza de té debe colocarse con precisión para garantizar que el patrón se imprime en la posición correcta.

Nuestro sistema de posicionamiento automático utiliza calibración multipunto y tecnología de detección inteligente para lograr una fijación eficiente y estable del cuerpo de la taza. Por un lado, este sistema reduce en gran medida los errores de operación manual; por otro, se adapta a tazas de té de diferentes tamaños y formas, sentando una base sólida para la posterior impresión de alta calidad.

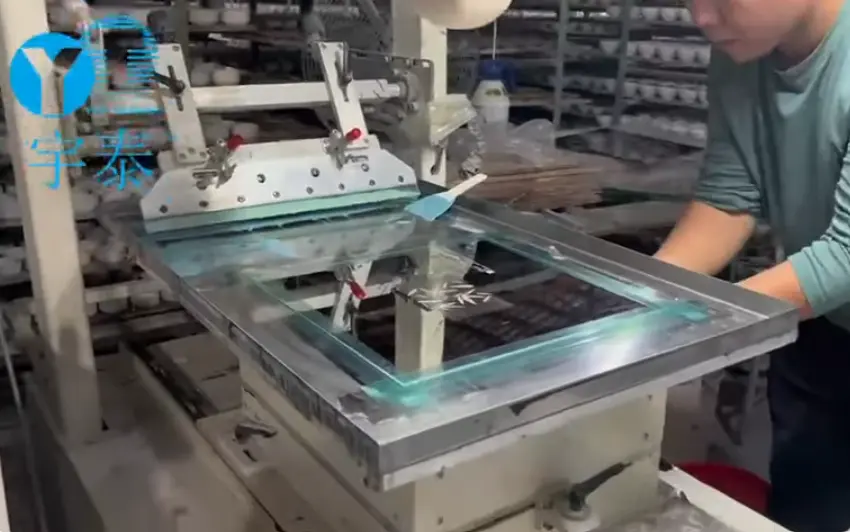

Proceso de impresión de tazas de té: transferencia eficaz de patrones

Tras completar el posicionamiento, el impresora de tampón cerámico empieza a trabajar formalmente. Todo el proceso incluye principalmente:

- Suministro automático de vasos y transporte giratorio

- Descenso automático del cabezal de tampografía o de la plancha de serigrafía para completar la transferencia del patrón

- Sistema de raspado y limpieza de la tinta para garantizar que cada impresión sea limpia y ordenada

Yutai impresora de tampón cerámico adopta un servosistema de alta precisión, y la acción de impresión es suave y estable. Incluso los patrones delicados y complejos pueden presentarse perfectamente, con colores uniformes y bordes nítidos, lo que aumenta enormemente el valor añadido y el atractivo comercial del producto.

Tratamiento posterior y curado

Tras la impresión, las tazas de té suelen necesitar un proceso de curado para garantizar que el dibujo sea resistente al desgaste y lavable.

Con nuestro eficaz equipo de secado, el proceso de curado de la tinta puede completarse en poco tiempo, acortando el ciclo de producción y mejorando la capacidad de producción global.

¿Por qué elegir la máquina de impresión cerámica automática Yutai?

- Equipos automáticos: permite el posicionamiento automático, el suministro automático de vasos y la impresión automática, lo que reduce considerablemente los costes de mano de obra.

- Impresión de alta precisión: Tanto si se trata de un patrón de gran superficie como de un logotipo pequeño, puede lograr una transferencia de alta calidad.

- Diseño modular: Es conveniente para los clientes configurar de forma flexible según sus necesidades y adaptarse rápidamente a diferentes tipos de pedidos.

- Servicio mundial de asistencia: Desde la selección de equipos hasta su instalación y puesta en marcha, le ofrecemos servicio profesional integral de maquinaria cerámica.

En la feroz competencia del mercado de las vajillas de cerámica, elegir un conjunto de máquina de impresión cerámica es la clave para mejorar la imagen de marca y la competitividad de los productos. Como proveedor fiable de máquinas de cerámica, Yutai le ayuda a crear fácilmente una línea de impresión de vajillas de cerámica de alta calidad.

Conclusión

En cada detalle de la impresión de tazas de té de cerámica, la eficiencia, la precisión y la estabilidad son la clave para destacar en el mercado. Nos comprometemos a proporcionar soluciones automatizadas para la producción de vajillas de cerámica a clientes de todo el mundo. Si busca un máquina de impresión cerámica para aumentar la capacidad de producción, optimizar los procesos y mejorar la competitividad, Yutai será su socio ideal. Póngase en contacto con nosotros y obtenga más información para que su producción sea más eficaz y sus productos mejores.