Producing high-quality decorative ceramics, whether tableware, ornaments, or specialty pieces, requires precision, consistency, and efficiency. Modern ceramic manufacturers rely on advanced moulding machinery to meet global production standards.In this article, we’ll explore how each technique works, its advantages, and why investing in the right machinery is essential for large-scale production plant.

Slip Casting Machines: Ideal for Complex Decorative Designs

Slip casting involves pouring liquid clay (slip) into plaster molds, allowing it to solidify and form intricate shapes. This method is perfect for ornamental ceramics, delicate tableware, and small batch production.

Benefits:

- Produces complex and delicate designs with fine details

- Suitable for customized and small-batch production

- Reduces manual labor for intricate shapes

- Compatible with glazing and surface decoration

Machinery Advantage: Modern automatic slip casting machines improve production speed, consistency, and wall thickness accuracy, ensuring every piece meets high-quality standards.

Ceramic Jigger Machines: Efficient for Round Tableware

Ceramic jiggering machines are widely used for plates, bowls, and circular decorative items. The clay is shaped on a rotating mold using a profile tool.

Advantages:

- Ensures uniform thickness and smooth surfaces

- High production efficiency for medium to large batches

- Ideal for tableware factories requiring consistent shape and finish

- Reduces post-processing and manual finishing

Use Case: Perfect for mass production of plates, bowls, and decorative circular ceramics, combining speed with quality.

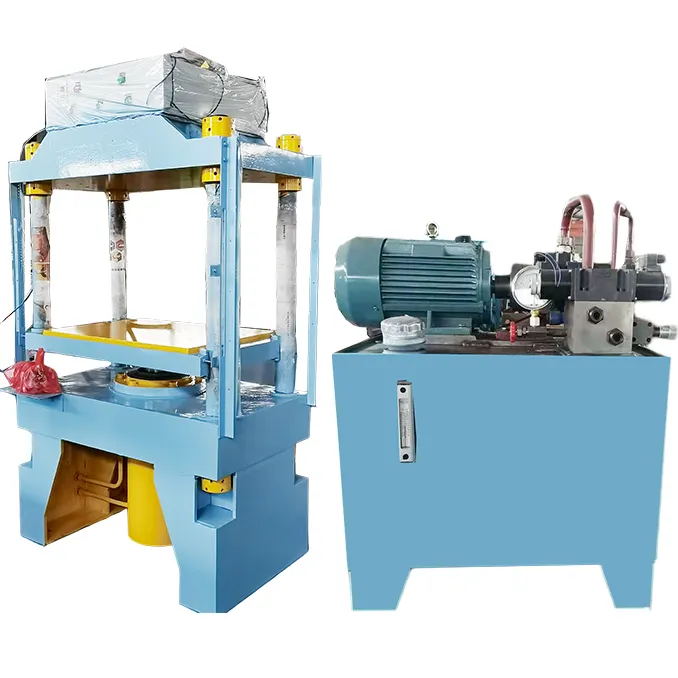

High-Pressure Presses: Precision and Strength for Decorative Items

High-pressure presses ceramic machines are used to shape clay under significant pressure, producing dense and strong ceramic pieces. This technique is particularly useful for decorative tiles, ornamental pieces, and sanitary components that require uniform density and structural integrity.

Benefits:

- Produces high-strength, defect-free ceramics

- Supports complex shapes with embossed or textured surfaces

- Suitable for large-scale production with consistent quality

Machinery Advantage: Modern high-pressure presses can be fully automated, reducing labor and ensuring repeatable results for large batches.

Why Using the Right Machinery Matters

Investing in slip casting machines, jigger machines, and high-pressure presses enables manufacturers to:

- Maintain consistent quality and precision

- Improve production efficiency and output

- Support custom decorative designs

- Reduce material waste and manual labor costs

These machines are especially valuable for large-scale production plant who need reliable, scalable production lines for tableware, ornaments, or specialty decorative ceramics.

Conclusion:

Decorative ceramic moulding combines artistry, precision, and efficiency. By leveraging slip casting, ceramic jigger machines, and high-pressure presses, manufacturers can consistently produce high-quality ceramics that meet international standards.

For factories seeking custom machinery or full production solutions, partnering with a professional ceramic machinery manufacturer ensures reliable quality, optimized production, and long-term support.

Contact us today to discuss decorative ceramic machinery solutions tailored to your production needs.