Bei der Keramikherstellung bestimmt die Tonherstellung die Textur, die Farbe und die Gesamtqualität des Keramikprodukts. In diesem Artikel werden wir den Prozess der Tonherstellung und die wichtigsten Maschinen zur Tonherstellung die darin verwendet werden.

Prozess der Tonerstellung

Der Prozess der Tonherstellung ist komplex und entscheidend für die Vorproduktion von Keramikprodukten. Er umfasst die Sammlung von Rohstoffen, das Zerkleinern und Mahlen, das Sieben von Tonpartikeln und die Aufbereitung von Schlamm. Nach sorgfältiger Auswahl und Vorbehandlung werden die Rohstoffe zur Feinbearbeitung in spezielle Maschinen geleitet, und schließlich wird das für die Keramikproduktion geeignete Tonmaterial gewonnen.

Sammlung keramischer Tonrohstoffe

Zu den wichtigsten Rohstoffen für keramischen Ton gehören Ton, Feldspat und Quarz. Die Reinheit und das Verhältnis dieser Rohstoffe wirken sich direkt auf die Endqualität des keramischen Produkts aus. Unterschiedliche Rohstoffe können den keramischen Erzeugnissen unterschiedliche physikalische und chemische Eigenschaften verleihen, daher ist es wichtig, die richtigen Rohstoffe zu wählen.

Maschinen zur Herstellung keramischen Tons

Um die Qualität und Produktivität keramischer Tone zu gewährleisten, ist die moderne Keramikindustrie auf eine Reihe effizienter Maschinen und Anlagen angewiesen. Dazu gehören Kugelmühlen, Enteisenungsmaschinen, Rüttelsiebe, Kolbenpumpen, Filterpressen, Tonmühlen und Tonschneider.

Kugelmühlen

Kugelmühlen mahlen das Rohmaterial durch rotierende Stahlkugeln in einem Mahlzylinder, um es weiter zu verfeinern. Kugelmühlen machen die Tonpartikel nicht nur gleichmäßiger, sondern erhöhen auch die Plastizität und Festigkeit des Tons. Dies ist eine wesentliche Voraussetzung für die Herstellung hochwertiger keramischer Erzeugnisse.

Maschine zur Eisenentfernungs

Eisenentferner werden verwendet, um Eisenverunreinigungen aus dem Ton zu entfernen, um schwarze Flecken und Unregelmäßigkeiten beim Brennen zu vermeiden. Zu den Arten von Enteisenungsmaschinen gehören Magnetabscheider und elektromagnetische Enteisenungsmaschinen. Das Verfahren zur Eisenentfernung kann das Aussehen und die Qualität von Keramikprodukten erheblich verbessern.

Vibrationssiebe

Vibrationssiebe werden verwendet, um Partikel unterschiedlicher Größe zu trennen und die Einheitlichkeit der Tonpartikel zu gewährleisten. Vibrationssiebe sind wirksam bei der Entfernung von Verunreinigungen und minderwertigen Partikeln und verbessern die Reinheit des Tons.

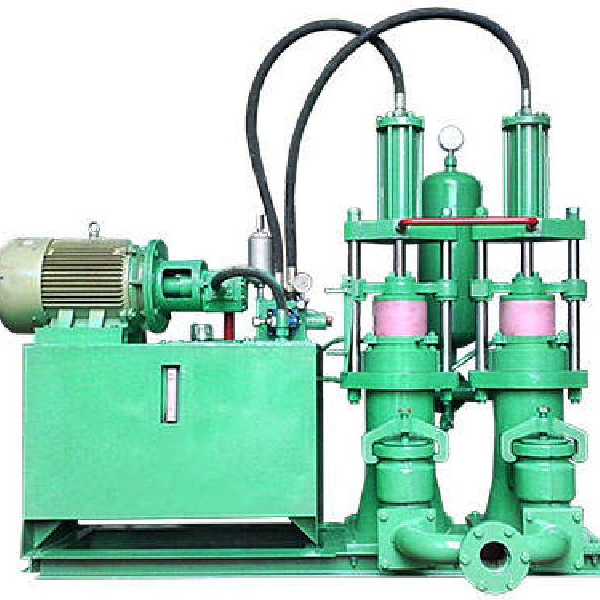

Kolbenpumpe

Die Kolbenpumpe ist eine effiziente Schlammförderanlage, die den Schlamm durch die Hin- und Herbewegung des Kolbens von einem Ort zum anderen befördert. Der Einsatz einer Kolbenpumpe gewährleistet die Kontinuität und Stabilität des Schlammförderungsprozesses und trägt zur Verbesserung der Produktionseffizienz bei.

Filterpresse

Die Filterpresse entzieht dem Schlamm durch mechanischen Druck überschüssiges Wasser und erhöht die Dichte und Plastizität des Schlamms. Die Filterpresse spielt eine Schlüsselrolle bei der Herstellung hochwertiger keramischer Tone, da sie Luftblasen und Poren im Ton erheblich reduziert.

Vakuum-Kugelmühle

Vakuumknetmühlen werden eingesetzt, um verschiedene Rohstoffe zu einem homogenen Brei zu vermischen. Das kontinuierliche Mischen und Kneten des Tons gewährleistet Homogenität und Plastizität und verhindert Luftblasen und Risse im Endprodukt.

Schlammschneidemaschine

Der Schlammschneider wird verwendet, um den vorbereiteten Schlamm in für die Verarbeitung geeignete Größen zu schneiden. Der Abschneider bietet eine präzise Kontrolle über die Größe und Form des Tons und verbessert so die Produktivität und Produktkonsistenz.

Zukünftige Trends in der Tonherstellung

Mit dem kontinuierlichen Fortschritt von Wissenschaft und Technik und dem Umweltbewusstsein werden die Maschinen zur Herstellung von Keramik zunehmend automatisiert und intelligent. Das Konzept der umweltfreundlichen und energiesparenden Produktion macht die Keramikproduktion grüner und nachhaltiger. In Zukunft wird die technologische Innovation eine solidere Grundlage für die Herstellung von Keramikprodukten bilden.

Schlussfolgerung

Der Prozess der Herstellung von keramischem Ton ist ein wichtiges Bindeglied in der keramischen Produktion. Die Auswahl geeigneter mechanischer Ausrüstung kann nicht nur die Effizienz der Produktion verbessern, sondern auch die Produktqualität sicherstellen. Als Hersteller von keramischen Maschinen hat Yutai mehr als 20 Jahre Erfahrung in der keramischen Fertigungsindustrie, und wir hoffen, mehr technische Probleme und innovative Ideen von keramischen Maschinen mit Ihnen durch den Artikel zu teilen. Wenn Sie Fragen haben oder mehr über unsere keramischen Maschinen wissen möchten, zögern Sie bitte nicht, uns zu kontaktieren. Wir verpflichten uns, umfassende Dienstleistungen und Qualitätsmaschinen für jeden keramischen Unternehmer anzubieten.