In der modernen Keramikherstellung wirken sich die Qualität und Effizienz des Glasierprozesses direkt auf das Aussehen, die Leistung und die Gesamtproduktionskapazität des Produkts aus. Die Frage, wie die Konsistenz und Effizienz des Glasierprozesses verbessert werden kann, stand daher schon immer im Mittelpunkt des Interesses der Keramikunternehmen. Als professioneller Hersteller von Keramikmaschinen, Yutai verpflichtet sich, den Keramikherstellern mit effiziente und stabile Automatisierungslösung für keramische Glasuren um den Kunden zu helfen, die beiden Ziele Kapazitätssteigerung und Qualitätsoptimierung zu erreichen.

Die traditionelle manuelle Bedienung der Verglasung hat ihre Grenzen

In herkömmlichen keramischen Produktionslinien wird das Glasieren meist manuell durchgeführt, was viele Herausforderungen mit sich bringt:

- Eine ungleichmäßige Glasurstärke beeinträchtigt die Produktkonsistenz.

- Schwere Glasurabfälle und schwierige Kostenkontrolle.

- Geringe Effizienz und Schwierigkeiten bei der Deckung des Bedarfs an Großaufträgen.

- Hohe Abhängigkeit von der Bedienertechnologie und hohe Kosten für die Schulung der Mitarbeiter.

Diese Probleme beeinträchtigen nicht nur die Produktionseffizienz, sondern schränken auch die Standardisierung und die Wettbewerbsfähigkeit der keramischen Erzeugnisse auf dem Markt ein.

Vorteile der Automatisierungslösung für Keramikverglasung

Verbesserung der Konsistenz der Verglasung: Automatische Keramik-Glasiermaschine kann die Konsistenz und Stabilität der Verglasung erheblich verbessern und menschliche Fehler reduzieren, indem es den Winkel, den Druck, den Durchfluss und die Flugbahn der Spritzpistole genau steuert.

Verbesserung der Produktionseffizienz: Das automatische Verglasungssystem kann eine kontinuierliche und ununterbrochene Verglasung erreichen und sich mit anderen Gliedern der Produktionslinie synchronisieren, um die Gesamteffizienz der Produktion erheblich zu verbessern.

Arbeitskosten sparen: Vor dem Hintergrund des zunehmenden Arbeitskräftemangels in der keramischen Industrie kann die Einführung automatisierter Anlagen die Abhängigkeit von Arbeitskräften erheblich verringern und die Arbeitsrisiken und -kosten senken.

Yutai Ceramic Glazing Automatisierungslösung

Das automatische Keramikverglasungssystem von Yutaihat sich mit seinen Vorteilen wie hohe Präzision, hohe Stabilität und hohe Automatisierung in Keramikfabriken auf der ganzen Welt einen guten Ruf erworben.

Hochgradig automatisiertes Betriebssystem

Das Design ist einfach zu bedienen, intuitiv zu steuern und benutzerfreundlich, um einen reibungslosen Betrieb zu gewährleisten. Der geringe Schulungsbedarf hilft den Arbeitern, sich schnell einzuarbeiten, und reduziert Fehlbedienungen.

Präzisionsspritzen mit mehrachsigem Gestänge

Der mehrachsige Servomotorantrieb und die glockenförmige Verglasungsvorrichtung können in Verbindung mit dem Flugbahnplanungssystem die Bewegungsbahn der Spritzpistole im dreidimensionalen Raum genau steuern, um eine gleichmäßige Glasurabdeckung und glatte Kanten zu gewährleisten.

Glassparendes Design

Das System optimiert die Menge des Glasurauftrags, reduziert effektiv den Abfall während des Glasurauftrags, verbessert die Ausnutzung der Glasur und hilft Unternehmen, eine umweltfreundliche Produktion zu erreichen.

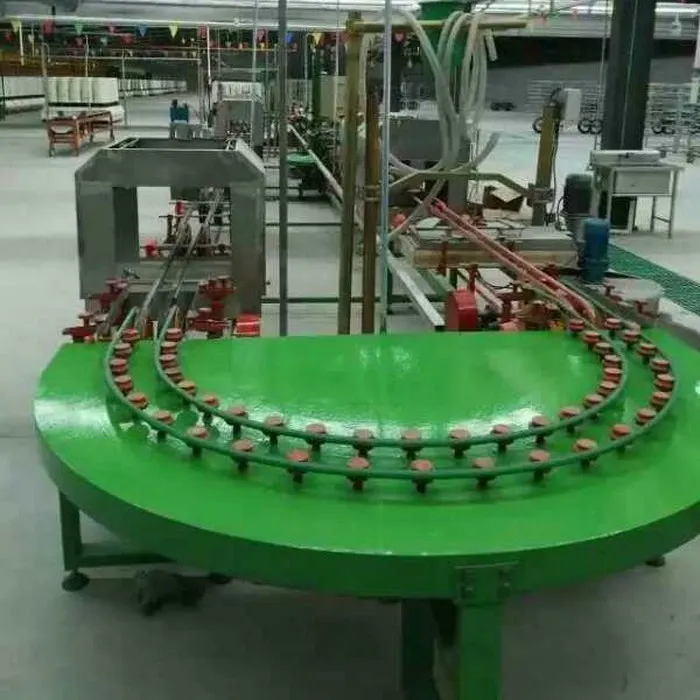

Hocheffiziente integrierte Keramikproduktionslinie

Keramik-Glasiermaschine von Yutai kann als Teil einer vollautomatischen keramischen Produktionslinie eingesetzt und mit vor- und nachgelagerten Anlagen verbunden werden, um den Produktionsfluss insgesamt zu verbessern.

Cearmic-Maschine nach Maß Optionen

Keramische Glasiermaschinen kann entsprechend den spezifischen Produktionsanforderungen angepasst werden, einschließlich zusätzlicher Arbeitsstationen oder spezieller Sprühmechanismen, um einzigartige Produktionsanforderungen zu erfüllen.

Yutai vollautomatische Keramikproduktionslinie

Yutai bietet nicht nur Einzelverglasungen an, sondern achtet auch verstärkt auf die Verbesserung der Effizienz der Gesamtlösung.

Durch die Integration der Verglasungsautomat mit der automatischen Formmaschine, der Trockenanlage, dem Ofen und anderen Keramikautomaten in die komplette Produktionslinie, können Keramikhersteller erreichen:

- Kontinuierlicher und reibungsloser Produktionsrhythmus.

- Reduzieren Sie menschliche Eingriffe und verbessern Sie die Produktstandardisierung.

- Visualisierung von Produktionsprozessdaten zur einfachen Überwachung und Verwaltung.

Schlussfolgerung

Als führender Hersteller von KeramikmaschinenYutai hilft Keramikherstellern, die Produktqualität zu verbessern und gleichzeitig ein kostengünstigeres und effizienteres Produktionsmodell zu erreichen. Wenn Sie auf der Suche sind nach stabil, effizient und leicht zu integrieren Automatisierungslösung für KeramikverglasungBitte kontaktieren Sie uns, um ein Angebot zu erhalten!