بوصفها فعالة ماكينات طباعة السيراميك, ماكينات طباعة السيراميك الوسادة السيراميك تحسين جودة المنتج وتقليل التكاليف بالنسبة لمصنعي السيراميك، كما أنه يستخدم بشكل متزايد في تصنيع السيراميك. شركة يوتاي لتصنيع آلات السيراميك سيقدم دليلاً شاملاً لطابعات الوسائد للسيراميك، مع شرح وتقديم نصائح وحلول احترافية من مبدأ العمل والمزايا والتطبيقات.

ما هي ماكينة طباعة الوسادة الخزفية؟

A طابعة وسادة السيراميك هي آلة تُستخدم خصيصاً لطباعة الأنماط على منتجات السيراميك. تستخدم تقنية طباعة خاصة تسمى "طباعة الوسادة" وتستخدم وسادة سيليكون ناعمة (تُسمى أيضًا وسادة طباعة الوسادة) لنقل الأنماط من سطح مستوٍ إلى آخر. وبعبارات بسيطة، تُعد طابعة الوسادة الخزفية بمثابة "ختم" فائق الذكاء يمكنه مساعدتنا في "ختم" أنماط جميلة بشكل مثالي على منتجات السيراميك بمختلف أشكالها.

كيف تعمل طباعة الوسادة?

مكونات ماكينة طباعة الوسادة الخزفية : اللوحة وكوب الحبر وطرف الوسادة اللاصقة , الذراع الروبوتية أو الحزام الناقل ونظام التحكم

مرحلة التحضير

صنع لوحة: أولاً، تحتاج إلى صنع لوحة بالتصميم الذي تريد طباعته. عادةً ما يكون هذا اللوح مصنوعًا من المعدن أو البلاستيك ويحتوي على أخاديد مقطوعة فيه لتشكيل التصميم.

التحبير: بعد ذلك، يتم طلاء اللوحة بحبر مُعد خصيصاً للسيراميك. هذا الحبر خاص لأنه يتحمل درجات الحرارة العالية، لذلك لن يبهت حتى بعد الحرق.

مرحلة الطباعة

نقل الحبر: بعد ذلك، يتم استخدام طرف سيليكون ناعم (يشبه الممحاة إلى حد ما) لملامسة الحبر على اللوحة. عندما يلمس طرف السيليكون اللوحة، فإنه يمتص الحبر في الأخاديد.

نقل النمط: الخطوة الأخيرة هي الضغط على طرف السيليكون المحبر على السيراميك. يؤدي ذلك إلى نقل الحبر إلى سطح السيراميك لتشكيل التصميم النهائي. تتطلب هذه الخطوة دقة كبيرة لضمان طباعة النمط في المكان الصحيح دون أخطاء.

تشبه العملية برمتها عملية الختم بختم الختم، ولكنها أكثر دقة واحترافية، مما يضمن إمكانية رؤية حتى الأنماط المعقدة بوضوح على السيراميك.

علاج الأيل

التلبيد أو التجفيف: يتم لصق الحبر بشكل دائم بالسيراميك عن طريق حرقه في فرن في درجات حرارة عالية جداً، مما يضمن أن المنتج النهائي ليس جميلاً فحسب، بل متيناً أيضاً وغير قابل للبهتان.

مزايا ماكينات طباعة الوسادة الخزفية

معالجة التفاصيل: يمكن نقل التصميم بشكل جيد حتى على الأسطح غير المستوية أو المنحنية باستخدام وسادات سيليكون ناعمة، مما يضمن إمكانية عرض كل التفاصيل الصغيرة للتصميم بوضوح.

فعالة واقتصادية: للإنتاج بكميات كبيرة، باستخدام طابعة الوسادة سريعة وفعالة من حيث التكلفة. الإعداد البسيط وتكاليف التشغيل المنخفضة تجعلها مثالية للتصنيع على نطاق واسع.

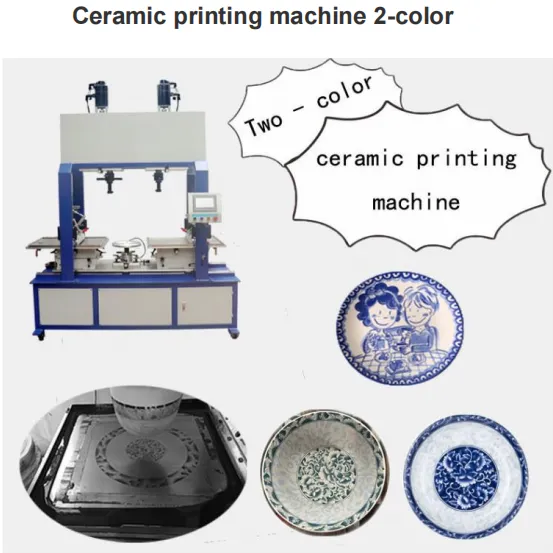

طباعة ملونة: يمكن لطابعة الوسادة إكمال مهام الطباعة متعددة الألوان بسهولة، مما يسهل إنشاء منتجات خزفية ملونة ومعقدة.

صديقة للبيئة: تعمل العديد من الموديلات الجديدة من طابعات الوسائد الخزفية بأحبار ذات تأثير منخفض على البيئة، الأمر الذي لا يقلل من النفايات فحسب، بل إنه أكثر صداقة للبيئة أيضًا.

تطبيقات ماكينات طباعة الوسادة الخزفية

الديكور المنزلي، يمكن لماكينات طباعة الوسادة الخزفية تحقيق أنماط رائعة أو شعارات العلامة التجارية على أدوات المائدة مثل البلاط والأطباق والأوعية والأكواب والمزهريات وغيرها من الزخارف، مما يزيد من جمال المنتجات والتعرف عليها.

الهدايا والهدايا التذكارية: مثل الأكواب وإطارات الصور وسلاسل المفاتيح والهدايا التذكارية الخزفية وما إلى ذلك، يمكن لآلات طباعة الوسادة طباعة أنماط مميزة أو مبانٍ بارزة.

إنتاج الأعمال الفنية: على المنحوتات الخزفية أو المشغولات اليدوية، يمكن لآلات طباعة الوسادة الخزفية أن تخلق تفاصيل وألواناً معقدة، مما يجعلها أكثر إبداعاً وزخرفة.

الخاتمة

ماكينات طباعة الوسادة السيراميك لا يمكنها تلبية احتياجات الإنتاج على نطاق واسع فحسب، بل يمكنها أيضًا تحقيق درجة عالية من التخصيص والتخصيص، مما يوفر مرونة كبيرة، وهي مثالية لصنع منتجات خزفية رائعة.

إذا كنت ترغب في معرفة المزيد عن معلومات عن أسعار ماكينات طباعة السيراميك أو المجموعة الكاملة من سلسلة ماكينات طباعة السيراميك، يرجى الرجوع إلى ماكينة يوتاي للسيراميك. Yutai هي شركة رائدة في مجال تصنيع آلات السيراميك في الصين، وهي مكرسة لتوفير آلات تصنيع السيراميك من الألف إلى الياء، و حلول السيراميك الصناعية المتكاملة للسيراميك. مع 20 عامًا من الخبرة المهنية وخدمات الدعم الفني، نساعد كل عميل على بناء مصنع سيراميك ناجح!