في عملية إنتاج أدوات المائدة الخزفية، يعتبر الفاقد عاملًا مهمًا يؤثر على تكلفة الإنتاج وكفاءته. إن كيفية تقليل الفاقد من أدوات المائدة الخزفية في عملية الإنتاج وتحسين معدل الإنتاج هي القضية الأساسية التي تهم كل شركة لتصنيع السيراميك. وباعتبار أن مصنع ماكينات السيراميك المحترف، تتفهم شركة Yutai المصادر الرئيسية للخسارة في إنتاج أدوات المائدة الخزفية. سوف نجمع بين مزايا ماكينات السيراميك الآلية لتوفير حلول تحسين فعالة.

المصادر الرئيسية للفاقد في إنتاج أدوات المائدة الخزفية

1.نفايات المواد الخام: في عملية إنتاج السيراميك، قد يتم إهدار المواد الخام مثل الطين والتزجيج وما إلى ذلك بسبب النسب غير المتساوية أو التخزين غير السليم أو أخطاء التشغيل البشري.

2.الخسارة في عملية التشكيل: عمليات التشكيل اليدوية أو شبه الآلية التقليدية عرضة لتفاوت حجم وسمك المنتج، مما يزيد من معدل الخردة.

3- التلف أثناء التجفيف والحرق: يمكن أن يؤدي وقت التجفيف الطويل أو غير المتكافئ إلى تكسير السيراميك بسهولة، في حين أن التحكم غير المستقر في درجة الحرارة، والتصميم غير المعقول للفرن وطرق الوضع الخاطئة يمكن أن تسبب تشوهًا أو تشققًا أو اختلافًا في لون المنتجات أثناء الحرق.

4- فحص الجودة غير الدقيق: إذا كانت طريقة الفحص متخلفة، فمن السهل أن تتسبب في تدفق المنتجات المعيبة إلى السوق، مما يؤثر على سمعة العلامة التجارية، ويزيد أيضًا من معدلات إعادة العمل والخردة.

5.الطباعة وفقدان الطحن السفلي: قد تتسبب عملية الطباعة على السيراميك في حدوث أخطاء في الطباعة بسبب عدم دقة تحديد المواقع، وإذا لم تكن عملية الطحن السفلي دقيقة بما فيه الكفاية، فسوف تتسبب أيضًا في تلف المنتج.

6.خسارة التعبئة والتغليف والنقل: تؤدي طرق التغليف غير الصحيحة والتصادم أثناء النقل إلى زيادة معدل كسر أدوات المائدة الخزفية.

حل Yutai الأوتوماتيكي لتقليل الفاقد في ماكينات السيراميك

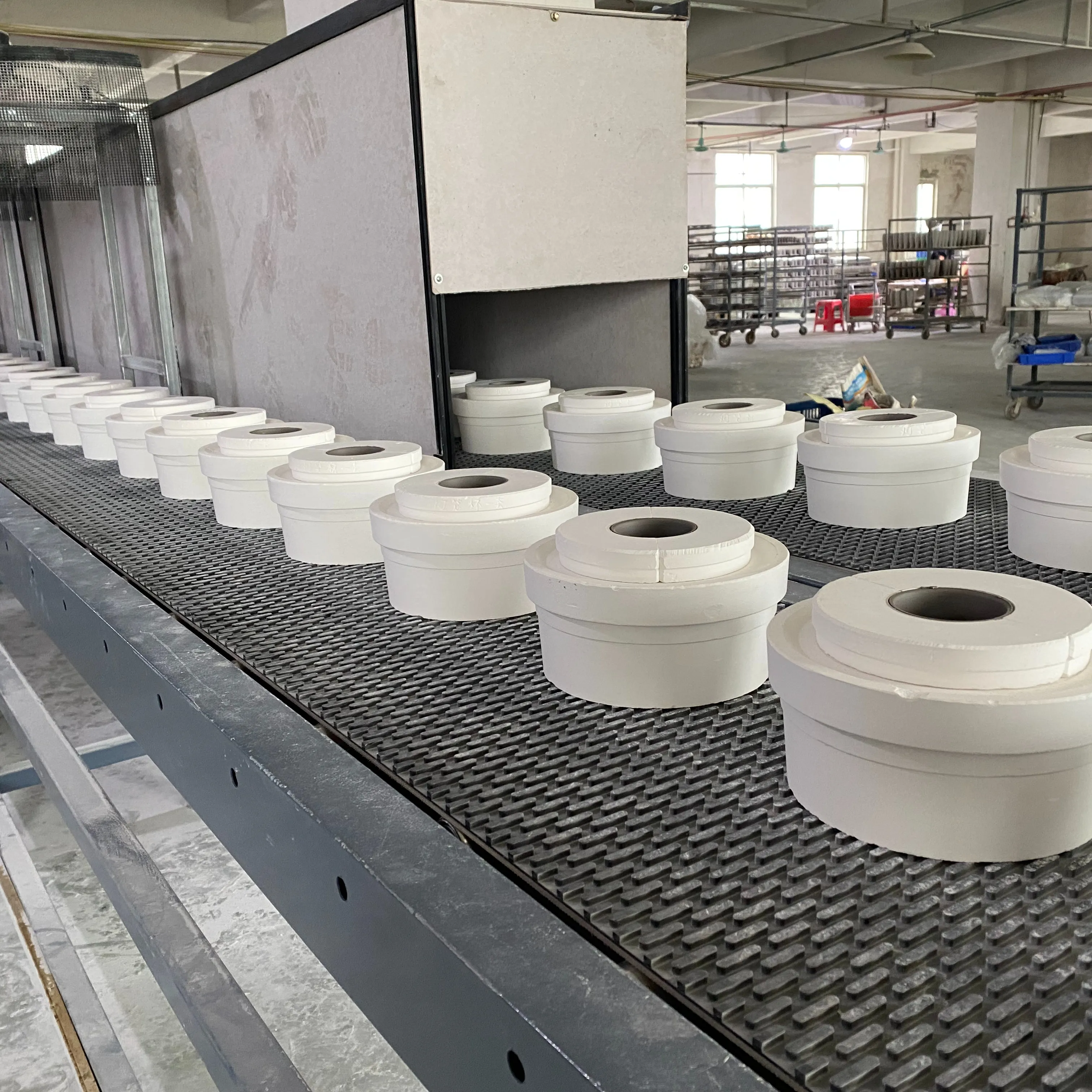

مع تطور تكنولوجيا الأتمتة، فإن خط إنتاج أدوات المائدة الخزفية الأوتوماتيكية بالكامل أصبحت وسيلة مهمة لتقليل الخسائر وتحسين كفاءة الإنتاج. وفيما يلي حل التحسين المحدد الذي توفره Yutai مع معدات الأتمتة لوصلات الإنتاج المختلفة:

تعمل ماكينات صنع الطين على تحسين استخدام المواد الخام

إن ماكينة صنع الطين تناسب وخلط الطين تلقائيًا، وتحسين معدل استخدام المواد الخام، وضمان توحيد الفراغات الخزفية، وتقليل النفايات الناجمة عن الأخطاء البشرية.

ماكينة تشكيل السيراميك، تحسين معدل الإنتاجية

استخدام ماكينات تشكيل السيراميك الأوتوماتيكية يمكن أن تضمن أن تكون سماكة أدوات المائدة موحدة والحجم دقيق، وبالتالي تقليل معدل العيوب. يمكن لتقنية التشكيل الذكي أيضًا تحسين سرعة الإنتاج وتحسين الاتساق وتقليل أخطاء التشغيل البشرية.

آلة تجفيف السيراميك تقلل من التشققات ومعدل التشوه

يمكن لماكينة تجفيف السيراميك توفير بيئة تجفيف موحدة ويمكن التحكم فيها لمنع التشققات الناجمة عن التجفيف غير المتساوي، وتحسين جودة الفراغ، وتقليل الفاقد في عملية الحرق اللاحقة.

تعمل ماكينات تزجيج السيراميك على تحسين جودة التزجيج

ماكينة التزجيج الأوتوماتيكية يمكن أن تضمن رشًا موحدًا للتزجيج، وتقلل من أخطاء التشغيل البشري، وتتجنب سماكة التزجيج غير المتساوية أو تدفق التزجيج، وبالتالي تحسين معدل الإنتاجية.

فرن سيراميك يتحكم بدقة في درجة حرارة الحرق

فرن السيراميك يمكن أن يحقق تحكمًا دقيقًا في درجة الحرارة وتوزيعًا موحدًا للحرارة، ويقلل من التشققات والتشوه واختلاف اللون أثناء الحرق.

تقلل ماكينات الطباعة السيراميك من أخطاء الطباعة

طابعات سيراميك متعددة الوظائف يمكن أن توفر طباعة عالية الدقة، وتضمن دقة الأنماط المطبوعة، وتقلل من أخطاء الطباعة، وتحسّن تناسق مظهر المنتج.

تعمل المطحنة السفلية الخزفية على تحسين دقة المعالجة

طاحنة قاع السيراميك يمكن أن تتحكم بدقة في تسطيح الطحن السفلي بدقة، وتجعل سطح منتجات السيراميك سلسًا وموحدًا، وتجنب تلف المنتج الناجم عن الطحن اليدوي غير المتساوي، وتحسين الجودة الشاملة للمنتجات النهائية.

الخاتمة

لا يؤثر الفاقد في إنتاج أدوات المائدة الخزفية على التكلفة فحسب، بل يقلل أيضًا من كفاءة الإنتاج والقدرة التنافسية للعلامة التجارية. من خلال إدخال معدات أدوات المائدة الخزفية الأوتوماتيكية مثل آلات صنع الطين وآلات تشكيل السيراميك والمجففات والمجففات والأفران وآلات التزجيج وآلات الطباعة والمطاحن السفلية وأدوات الماكينات، يمكن للشركات أن تقلل بشكل كبير من الخسائر في عملية الإنتاج، وتحسن معدل الإنتاج، وتحسن كفاءة الإنتاج، وبالتالي تحتل مكانة مواتية في المنافسة في السوق.

إذا كانت شركتك ترغب في ترقية خط إنتاج أدوات المائدة الخزفية الخاصة بها، وتحسين كفاءة الإنتاج وتقليل الخسائر، يرجى اتصل بنا لتتعلم كيف أن حل شامل لماكينات السيراميك يمكن أن تساعدك في تطوير أعمالك!