في عالم السيراميك، لا تزال التكنولوجيا تلعب دورًا حاسمًا في تعزيز كفاءة وجودة عمليات الإنتاج. وأحد هذه الابتكارات التي أحدثت تحولاً كبيرًا في صناعة السيراميك هو ماكينة تهزهز. أصبحت هذه الماكينة لا غنى عنها في إنتاج مختلف أنواع السيراميك، خاصةً في صناعة الأشكال المتناسقة بدقة واتساق. في هذه المدونة، سوف نستكشف في هذه المدونة ما هي ماكينات الرفع، وكيفية عملها، وتأثيرها على صناعة السيراميك.

ما هي ماكينة القفز؟

A ماكينة تهزهز هو جهاز لصناعة السيراميك يقوم، عن طريق التشكيل على عجلة دوارة، بإنتاج أشكال ثابتة من الطين. وهي مثالية لإنتاج الأشياء ذات التناسق المنتظم، مثل الأطباق والأوعية والصحون المستخدمة في صناعة أواني الطعام وأدوات المائدة. يمكن لتقنية القفز أن توفر سرعات عالية ودقة ممتازة، وهو أمر ضروري لإنتاج كميات كبيرة من السيراميك.

كيف تعمل ماكينة القفز بالحبال؟

وبوجه عام، تحدث عملية القفز على النحو التالي;

تحضير الطين: يتحول الطين إلى شكل جاهز من كرة أو كتلة مستديرة غير كاملة. وبشكل ثابت، يصبح محتوى الرطوبة أو عكسه أساسًا حاسمًا أثناء عملية التنعيم في عملية التنقيط الفعلية.

تحميل الطين يتم تحميل الطين على القالب الدوار، المصنوع عادةً من الجبس. يتم تشكيل القالب مسبقاً بالشكل المطلوب، مثل الطبق أو الوعاء.

تشكيل الطين يتم الضغط على أداة تُسمى "الرفش" على قالب الغزل. وعادةً ما يكون ذلك على شكل مغزل يحمل شكلًا جانبيًا مطابقًا للشكل الخارجي للقالب النهائي. تتحرك الرفرافة عبر قالب الغزل، لتقوم بتشكيل القالب مع إنشاء سطح أملس ومتساوٍ.

التجفيف: بعد التشكيل، تُترك القطعة الخزفية لتجف وتثبت قبل حرقها في الفرن. وبمجرد حرقها، تخضع للتزجيج وأي خطوات تشطيب نهائية.

أنواع ماكينات الحفر

هناك عدة أنواع من ماكينات القفز، كل منها مصمم لتلبية احتياجات إنتاج محددة:

ماكينات الرفع اليدوي هي تلك التي تعتمد على مشغل لتحريك أداة الرفع يدويًا. ومع ذلك فهي أبطأ من نظيراتها الآلية، ومع ذلك فهي تستخدم في عمليات الإنتاج الأصغر حجمًا أو للعناصر التي تتطلب درجة عالية من التخصيص.

ماكينات الحفر شبه الأوتوماتيكية: توفر هذه الماكينات توازنًا بين الأتمتة والتحكم اليدوي. تؤدي الماكينة معظم العمل، ولكن لا يزال المشغل مطالبًا بتحميل وتفريغ الطين وإجراء التعديلات حسب الحاجة.

ماكينات الحفر الأوتوماتيكية بالكامل: هذه الماكينات متطورة للغاية وقادرة على تنفيذ عملية الترقيع بالكامل بشكل مستقل. تُعد هذه الماكينات مثالية لتصنيع السيراميك على نطاق واسع، حيث توفر إنتاجًا عالي السرعة وتكاليف عمالة منخفضة.

فوائد ماكينات الحفر في إنتاج السيراميك:

ماكينات الحفر توفر العديد من المزايا في إنتاج السيراميك، بما في ذلك تعزيز الدقة والاتساق والسرعة. كما أنها تضمن تشكيلًا موحدًا، مما يقلل من العيوب ويضمن منتجات عالية الجودة وموحدة. من خلال أتمتة عملية التشكيل، تزيد ماكينات التشكيل من كفاءة الإنتاج بشكل كبير وتقلل من تكاليف العمالة، مع تقليل هدر المواد. إن تعدد استخداماتها يجعلها مناسبة لمجموعة واسعة من العناصر الخزفية، بدءًا من الأواني المسطحة إلى الأشكال الأكثر تعقيدًا، مما يجعلها أداة لا تقدر بثمن للتصنيع على نطاق واسع. بالإضافة إلى ذلك، تضمن قدرتها على الحفاظ على جودة متسقة عبر الإنتاج الضخم تحسين موثوقية المنتج.

استخدامات ماكينات الحفر الآلي

إن تعدد استخدامات ماكينات القفز يجعلها قابلة للتطبيق على مجموعة واسعة من منتجات السيراميك، بما في ذلك:

- أواني الطعام: يتم تصنيع الأطباق والأوعية والصحون التي تتطلب سمكًا موحدًا وحوافًا ناعمة بشكل شائع بواسطة ماكينات القفز.

- بلاط السيراميك: وهي عبارة عن بلاط سيراميك مسطح للأرضيات أو الجدران يمكن صنعه على ماكينات القفز.

- المزهريات والأواني: وعلى الرغم من أن عملية الترقيع ترتبط بالفعل بأدوات المائدة، إلا أنها تُستخدم أيضاً في الأدوات الأعمق والأكثر تعقيداً مثل المزهريات والأواني وغيرها من الحلي.

- معدات المختبرات: كما يتم تصنيع العديد من مكونات السيراميك المتخصصة للاستخدام الصناعي، مثل العوازل أو الأجزاء الكهربائية، على ماكينات القفز.

مستقبل ماكينات الحفر في صناعة السيراميك

احتمالات ماكينات القفز في المستقبل تبدو مشرقة مع التطور السريع للتكنولوجيا. وبالفعل، يؤدي دمج التقنيات الذكية في هذه الآلات بالفعل إلى زيادة الدقة والمراقبة في الوقت الحقيقي والصيانة التنبؤية من قبل الشركة المصنعة بشكل تدريجي. إلى جانب ذلك، ستوفر المعرفة الأحدث في علم المواد أخيرًا آلات متينة وموفرة للطاقة من أجل مزيد من التحسين في تصنيع السيراميك.

مع الطلب المتزايد على المنتجات المستدامة والصديقة للبيئة، لا بد أن يجد المصنعون طريقة لخفض استهلاك الطاقة وهدر المواد في عملية الرفع. ومن المحتمل أن يؤدي هذا الاتجاه نحو الاستدامة إلى تشكيل التطوير المستقبلي لماكينة الرفع لتكون أكثر صداقة للبيئة.

الخاتمة

إن ماكينة تهزهز أحدثت ثورة في صناعة السيراميك من خلال تحقيق الدقة والحد من الهدر وتسريع الإنتاج. بدءًا من الحِرَفية الصغيرة إلى الصناعية واسعة النطاق، ستكون ماكينات الرفع مفيدة للغاية في توفير مجموعة واسعة من منتجات السيراميك من خلال ضمان التوحيد والكفاءة في التعامل معها. لذلك، يعد فهم النماذج وقدرات كل منها نهجًا مهمًا في اختيار الماكينة المناسبة لاحتياجات الإنتاج المحددة. يمكن للمعدات المناسبة أن تقطع شوطًا طويلاً في تحسين جودة وكفاءة عملية تصنيع السيراميك.

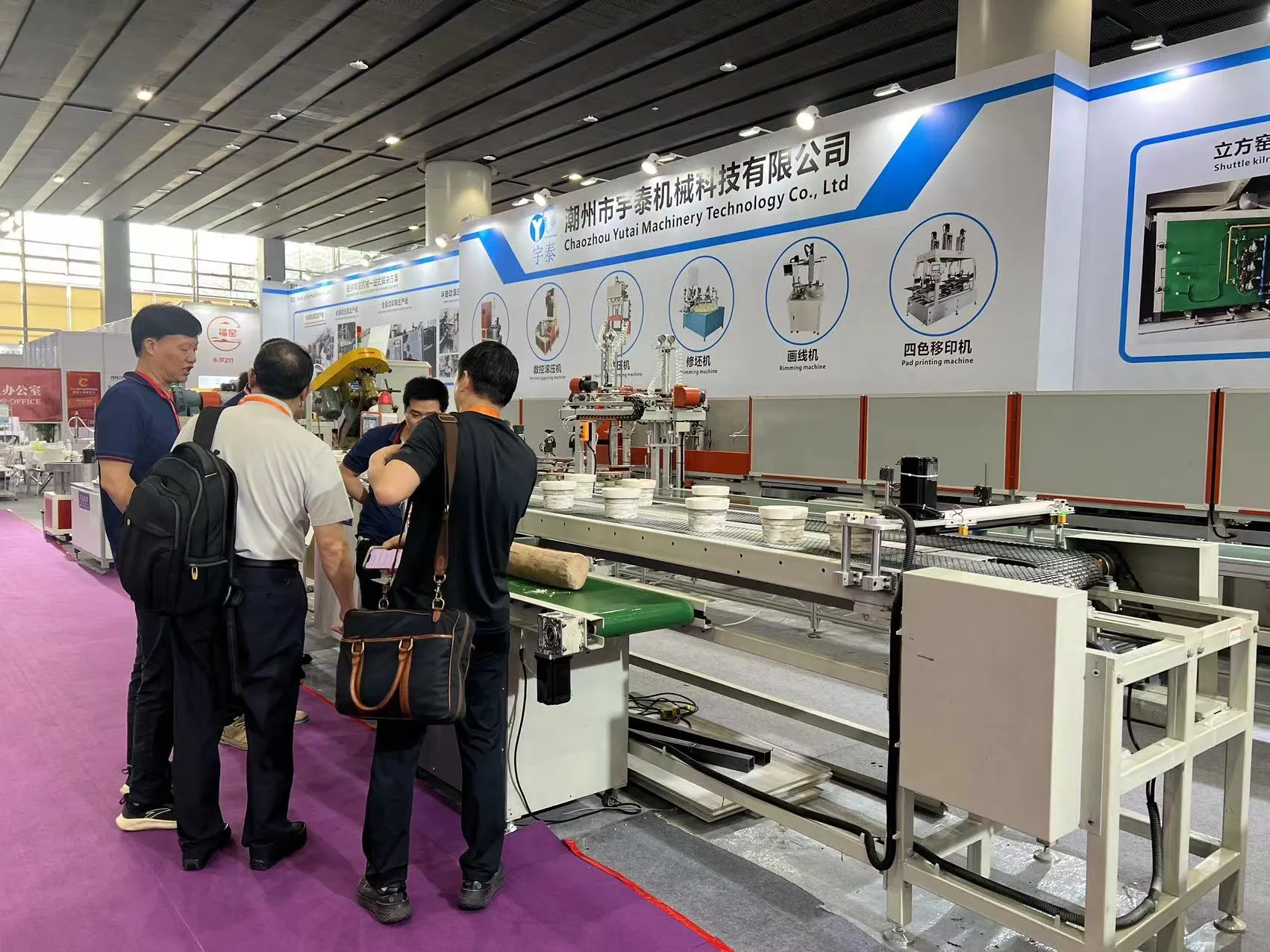

حلول وخدمات ماكينات الحفر لدينا

في مصنع يوتاي لماكينات السيراميكفإننا نقدم مجموعة من الحلول المتطورة لتلبية احتياجاتك في إنتاج السيراميك. لدينا ماكينات الرفع شبه الأوتوماتيكية والأوتوماتيكية بالكامل مصممة لتوفير التوازن المثالي بين الكفاءة والدقة. كما نقدم أيضًا خطوط إنتاج تشكيل السيراميك المؤتمتة بالكامل، والمصممة خصيصًا لتحسين سير عمل التصنيع لديك. سواء كنت تتطلع إلى تصنيع أواني الطعام أو البلاط أو السيراميك المتخصص، يمكن أن تساعدك حلولنا على توسيع نطاق عملياتك بكفاءة مع تقليل النفايات.

يكرِّس فريق الخبراء لدينا جهوده لدعمك طوال العملية بأكملها - بدءاً من اختيار المعدات المناسبة وحتى التركيب والتدريب. كما نقدم أيضاً خدمة ما بعد البيع لضمان استمرار آلاتك في تقديم أفضل أداء لها.

لا تتردد في الاتصال بنا اليوم لمعرفة المزيد عن ماكينات الرفع وخطوط إنتاج السيراميك لدينا، ودعنا نرتقي بقدراتك الإنتاجية إلى المستوى التالي باستخدام التكنولوجيا المتقدمة.