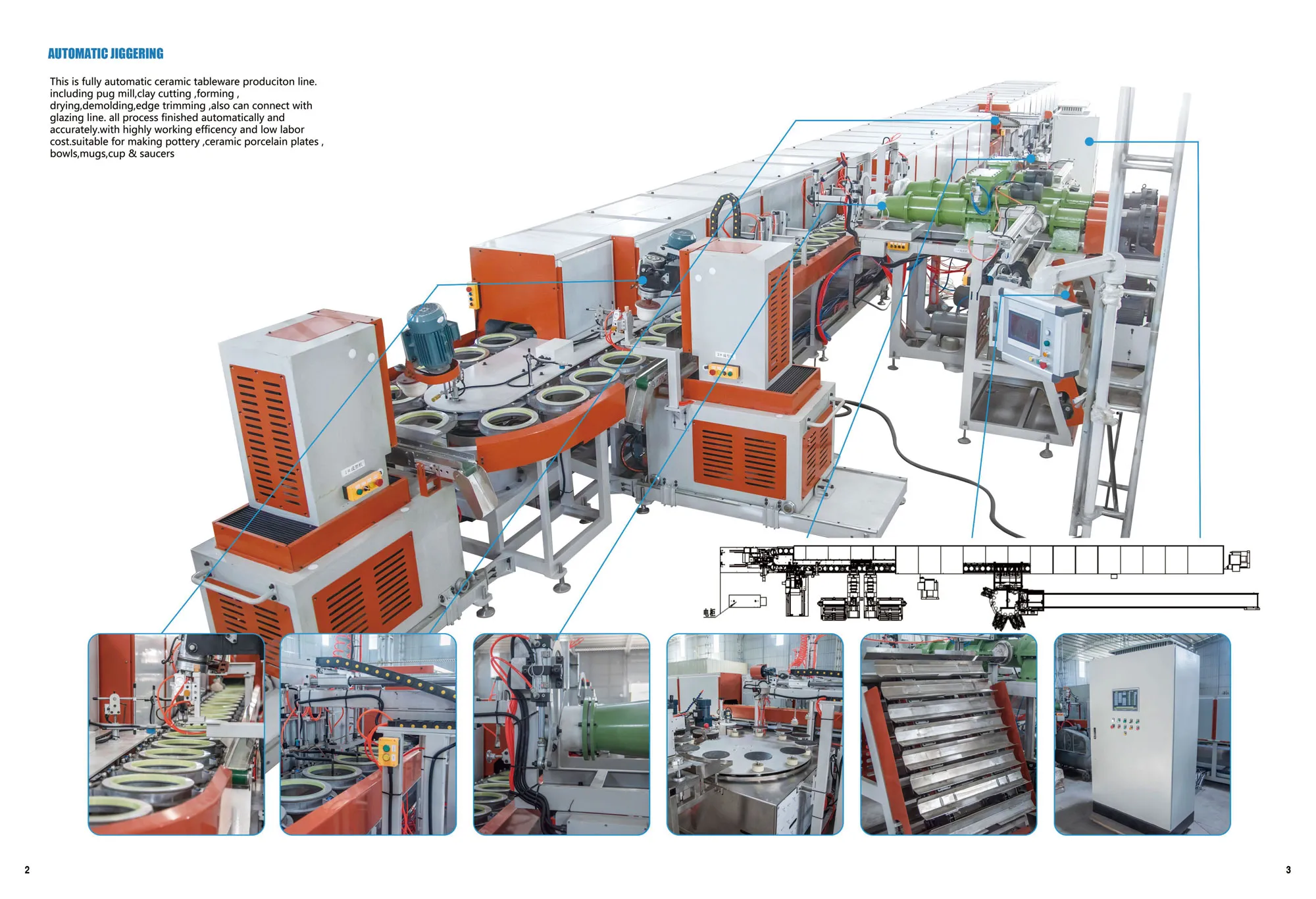

في أسواق الطعام والأثاث المنزلي التي تتسم بالتنافسية الشديدة اليوم، لا تجذب تصاميم أدوات المائدة الخزفية الفريدة من نوعها انتباه المستهلكين فحسب، بل تجلب أيضًا قيمة لا يمكن تعويضها للعلامة التجارية. مع تطور العلم والتكنولوجيا, آلات ومعدات السيراميك المتطورة أصبحت أداة مهمة لتحقيق هذه المفاهيم التصميمية الفريدة من نوعها. ستستكشف هذه المقالة كيفية استخدام تكنولوجيا ماكينات السيراميك الحديثة لدعم وتعزيز إنتاج أدوات المائدة الخزفية المخصصة، خاصة من منظور اقتراحات الشراء والتخصيص لتصنيع الماكينات.

تقنية القولبة الدقيقة

- القوالب الانزلاقية: مناسبة لصنع أدوات المائدة الخزفية ذات الأشكال المعقدة والجدران الرقيقة. من خلال التحكم الدقيق في سيولة الطين ودرجة حرارة القالب، يمكن ضمان اتساق حجم وشكل كل منتج.

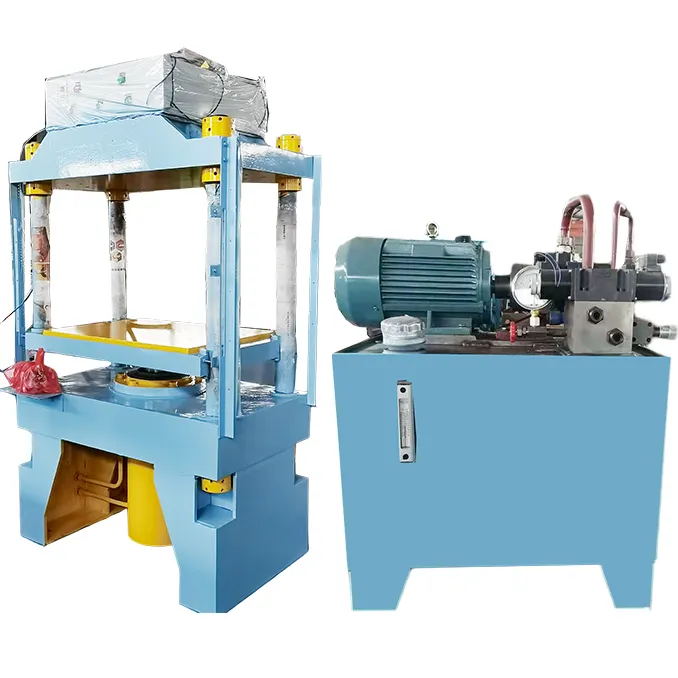

- صب القوالب بالكبس: بالنسبة لأدوات المائدة المسطحة أو أدوات المائدة من النوع المسطح أو الوعاء، يمكن لتقنية القولبة بالضغط أن تحقق إنتاجًا ضخمًا فعالاً. يمكن أن يؤدي استخدام أنظمة التحكم في الضغط المتقدمة إلى زيادة سرعة الإنتاج مع ضمان جودة المنتج.

- الطباعة ثلاثية الأبعاد: هذه التقنية مناسبة بشكل خاص لإنشاء تصميمات ذات أشكال هندسية معقدة. من خلال تكديس المواد طبقة بعد طبقة، يمكن للطباعة ثلاثية الأبعاد تحقيق تفاصيل وتأثيرات نسيج يصعب تحقيقها بالطرق التقليدية.

عملية الزخرفة الآلية

- رش الصقيل: يمكن أن يحقق استخدام مسدسات الرش الأوتوماتيكية تغطية زجاجية موحدة. وبالنسبة للإنتاج بكميات كبيرة، لا يحسن ذلك من الكفاءة فحسب، بل يضمن أيضًا اتساق مظهر كل منتج.

- شارة: يتم تصميم النمط من خلال برنامج التصميم بمساعدة الحاسوب (CAD)، ثم يتم نقله إلى ورق خاص باستخدام طابعة عالية الدقة ويتم تثبيته على سطح السيراميك. هذه الطريقة مناسبة جداً لتحقيق الأنماط المعقدة ومطابقة الألوان.

- النقش بالليزر: بالنسبة للمنتجات التي تتطلب نقشًا دقيقًا أو تخصيصًا شخصيًا، يمكن لتقنية النقش بالليزر تحقيق نقش دقيق للغاية للنصوص والنقوش دون الإضرار بهيكل المنتج.

تكنولوجيا الحرق الصديقة للبيئة والموفرة للطاقة

- فرن كهربائي: بالمقارنة مع أفران الغاز التقليدية، تتميز الأفران الكهربائية بدقة أفضل في التحكم في درجة الحرارة واستهلاك أقل للطاقة. وهذا مهم بشكل خاص لأدوات المائدة الخزفية المتطورة التي تتطلب تحكمًا صارمًا في منحنى الحرق.

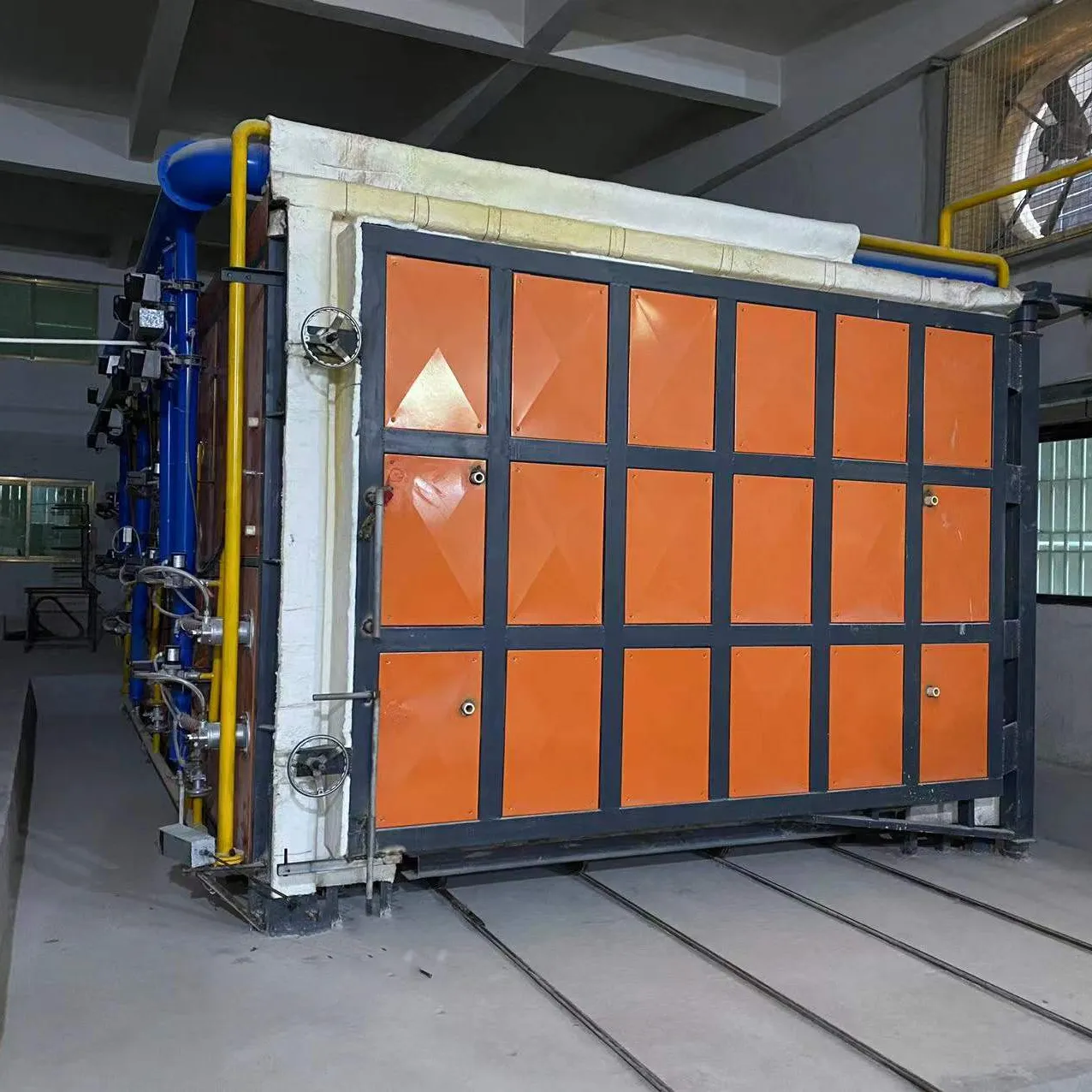

- الفرن النفقي المستمر: مناسب للإنتاج على نطاق واسع، من خلال تصميم توزيع تدفق الهواء داخل الفرن بشكل معقول، يمكنه تحسين كفاءة استخدام الطاقة بشكل كبير مع ضمان جودة المنتج المستقرة.

من النموذج الأولي إلى الإنتاج الضخم

- تصميم النموذج الأولي واختباره: قبل الدخول في الإنتاج الضخم، يجب عمل عدد صغير من النماذج الأولية للاختبار. يمكن لهذه المرحلة التحقق من جدوى التصميم، وتعديل أي جوانب غير مرغوب فيها، والتأكد من أن المنتج النهائي يلبي التوقعات.

- تحليل التكاليف والفوائد: تقييم التغيرات في التكلفة من النموذج الأولي إلى الإنتاج بكميات كبيرة، بما في ذلك تكاليف المواد وتكاليف العمالة واستهلاك المعدات وما إلى ذلك، لضمان الجدوى الاقتصادية للمشروع.

- تحسين عملية الإنتاج إلى الحد الأمثل: بعد نجاح اختبار النموذج الأولي، يجب تحسين عملية الإنتاج بأكملها لضمان تشغيل كل وصلة بكفاءة. على سبيل المثال، من خلال إدخال معدات آلية لتقليل تكاليف العمالة وتحسين كفاءة الإنتاج.

مراعاة أبعاد الحلول المخصصة

عندما تفكر في شراء أو تخصيص آلات ومعدات السيراميك، يمكنك التفكير من الأبعاد التالية:

- المتطلبات الوظيفية: وضح الوظائف المحددة التي تريد أن تحققها المعدات، مثل درجة الأتمتة ودقة التشكيل والتأثيرات الزخرفية وما إلى ذلك. قد تتطلب احتياجات الإنتاج المختلفة أنواعًا مختلفة من المعدات.

- مقياس الإنتاج: اختر النوع المناسب من المعدات بناءً على حجم إنتاجك (التخصيص على دفعات صغيرة مقابل الإنتاج على نطاق واسع). قد يتطلب التخصيص على دفعات صغيرة تهيئة معدات أكثر مرونة، بينما يتطلب الإنتاج على نطاق واسع خطوط إنتاج أكثر كفاءة.

- نطاق الميزانية: حدد نطاقاً معقولاً للميزانية واعثر على المعدات الأكثر فعالية من حيث التكلفة على هذا الأساس. وفي الوقت نفسه، ينبغي أيضاً مراعاة تكاليف التشغيل والصيانة على المدى الطويل والعائد المحتمل على الاستثمار.

- الدعم الفني والخدمة: اختر موردًا يتمتع بخدمة ما بعد البيع والدعم الفني الجيد لضمان حصولك على المساعدة الفعالة في الوقت المناسب عندما تواجه مشاكل أثناء استخدام المعدات.

- المعايير البيئية: مع ازدياد وعي المجتمع بحماية البيئة، تزداد أهمية اختيار المعدات التي تلبي المعايير البيئية. ضع في اعتبارك عوامل مثل نسبة كفاءة الطاقة للمعدات وقدرة معالجة الغازات العادمة ومياه الصرف الصحي.

حل تخصيص ماكينات يوتاي للسيراميك

خدمة مخصصة: نحن نقدم خدمات استشارية فردية ونفهم احتياجاتك بعمق ونوصي بالحل الأنسب لك.

تقنية متقدمة: استخدام أحدث تكنولوجيا آلات السيراميك لضمان الجودة العالية للمنتجات في التصميم والإنتاج والزخرفة.

استجابة سريعة: إنشاء آلية تواصل فعالة لضمان شفافية سير المشروع وسرعة الاستجابة لأي من احتياجاتك.

دعم شامل: بدءاً من تصميم النموذج الأولي وحتى الإنتاج الضخم، نوفر لك الدعم الفني الكامل وضمانات الخدمة لمساعدتك على إكمال كل مشروع بنجاح.

الخاتمة

آلات ومعدات السيراميك المتقدمة ليست فقط أداة لتحسين كفاءة الإنتاج، ولكنها أيضًا جسر لتحقيق الإبداع وأحلام التصميم. من خلال اعتماد هذه التقنيات المتطورة، يمكننا مساعدة العملاء على تحويل مفاهيم التصميم الفريدة إلى واقع ملموس وإنشاء أدوات مائدة خزفية مخصصة جميلة وعملية في آنٍ واحد. إذا كانت لديك أفكار إبداعية مماثلة، يُرجى الاتصال بنا ودعنا نستكشف المزيد من الإمكانيات معًا!