بالنسبة للمصانع الجديدة أو المصانع التي تخطط للتوسع والتحديث، يعد اختيار آلات تشكيل السيراميك المناسبة أمرًا بالغ الأهمية. لا يؤثر ذلك على كفاءة الإنتاج وجودة المنتج فحسب، بل يتعلق أيضًا بتكاليف الإنتاج والتطوير طويل الأجل. كشركة مصنعة محترفة لماكينات السيراميك يوتاي توفر مجموعة كاملة من ماكينات تشكيل السيراميك وكذلك خطوط إنتاج تشكيل السيراميك الأوتوماتيكية بالكامل. في هذه المقالة، سوف نصف ماكينات تشكيل السيراميك هذه ونساعدك على اختيار الحل الأنسب.

عملية تشكيل السيراميك

تشكيل السيراميك عملية معقدة، بما في ذلك صنع الطين, تشكيل السيراميك من خلال الضغط العالي، أو الدرفلة أو الصب، وأخيرًا الفرك الأولي للجسم المشكل. سيتم عرض المعدات الميكانيكية الرئيسية المستخدمة في عملية التشكيل بالتفصيل أدناه.

المعدات الرئيسية لماكينة تشكيل السيراميك

1. خلاط جبس تفريغ الهواء: تحضير الطين

- الوظيفة: تستخدم لتحضير ملاط السيراميك لضمان التوحيد واللزوجة المناسبة للملاط. يمكن لوظيفة التفريغ إزالة فقاعات الهواء وتحسين جودة المنتجات المقولبة.

- المزايا: تحسين الكثافة والتشطيب السطحي لمنتجات السيراميك بشكل كبير، وتقليل معدل عيوب المنتجات النهائية.

2. مضخة الحجاب الحاجز الهوائي: نقل المخزون

- الوظيفة: تُستخدم لنقل ومعالجة ملاط السيراميك، ونقل ملاط السيراميك من الخلاط إلى ماكينة التشكيل. ضمان التوحيد والاستقرار.

- المزايا: يمكنها نقل الملاط بكفاءة وثبات وتجنب الترسيب والتقسيم الطبقي.

3. ماكينة قطع الطين: إعداد المواد اللازمة للتدوير

- الوظيفة: إعداد الشكل المقابل من الطين لماكينة الرفع

- المعالجة: تقطيع الطين الخام إلى كتل مناسبة من خلال قاطع الطين لتسهيل عملية التشكيل اللاحقة.

4. ماكينات التشكيل المختلفة

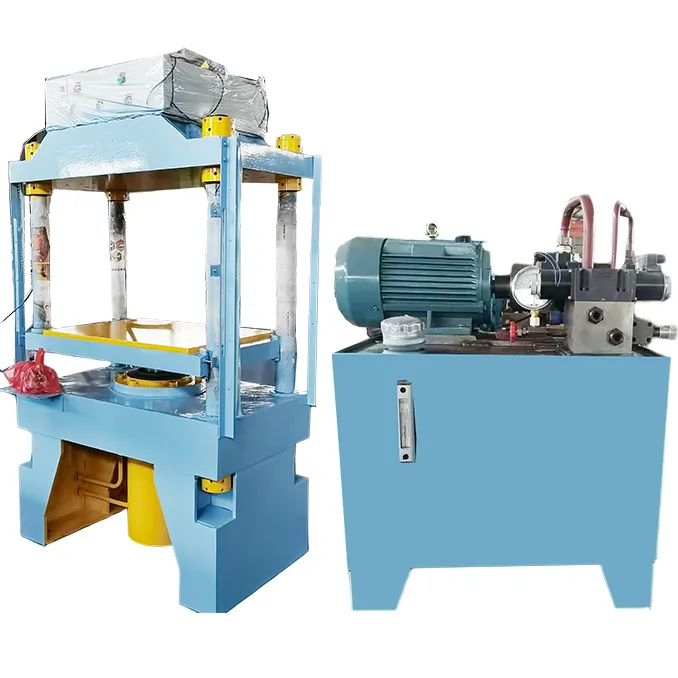

ماكينة كبس السيراميك

- المبدأ: وضع المسحوق في تجويف القالب، والضغط من خلال المسافة البادئة، وضغط المسحوق في تجويف القالب، وتشكيل فراغ خزفي بقوة وشكل معينين.

- المنتجات القابلة للتطبيق: مناسبة لإنتاج أدوات المائدة الخزفية ذات الأشكال المنتظمة والأبعاد الدقيقة، مثل الأطباق والأوعية والأكواب.

- المزايا: سرعة قولبة سريعة، وكثافة عالية للمنتج، ودقة أبعاد عالية، ومناسبة للإنتاج بكميات كبيرة.

ماكينة تهريج

- المبدأ: يتم استخدام رأس أسطوانة دوارة لتدوير الفراغ في نموذج يدور في نفس الاتجاه، ويتم فرد الفراغ بالتساوي لتشكيل جسم أخضر.

- المنتجات القابلة للتطبيق: مناسبة لإنتاج أدوات المائدة الخزفية ذات الأشكال المعقدة، مثل الأطباق والأوعية ذات النقوش.

- المزايا: القدرة على تحقيق قوام وأشكال سطحية معقدة، ومرونة إنتاج عالية.

ماكينة صب زلة السيراميك

- المبدأ: حقن الطين في نموذج الجص، واستخدام امتصاص الماء في نموذج الجص لتقليل الماء في الطين تدريجيًا لتحقيق الغرض من صب الجفاف.

- المنتجات القابلة للتطبيق: مناسبة لإنتاج أدوات المائدة الخزفية ذات الجدران الرقيقة وذات الهيكل الدقيق، مثل أباريق الشاي وأكواب القهوة والمزهريات.

- المزايا: إنها مناسبة لإنتاج المنتجات ذات الأشكال المعقدة وسُمك الجدار الرقيق، ويقل فقدان المواد أثناء عملية الإنتاج.

5. ماكينة الطحن والتلميع: التنظيف النهائي للعجلات

- الوظيفة: تستخدم لتنظيف ومعالجة أجسام السيراميك وإزالة الطين والشوائب الزائدة، وضمان نظافة الجسم.

- المزايا: تحسين تشطيب وجودة المنتجات النهائية، وتقليل كثافة العمالة في التنظيف اليدوي، وتحسين كفاءة الإنتاج.

6. خط إنتاج تشكيل السيراميك الأوتوماتيكي

- الوظيفة: يغطي كل خطوة من قطع الطين وتشكيله وتجفيفه وتشذيبه، ويمكن دمجه بسلاسة مع خط إنتاج التزجيج لتشكيل خط إنتاج مؤتمت بالكامل.

- المزايا: يحسن كفاءة الإنتاج بشكل كبير، ويقلل من تكاليف العمالة، ويضمن اتساق جودة المنتج. إنه خيار مثالي للإنتاج على نطاق واسع.

كيفية اختيار ماكينة تشكيل السيراميك

يتطلب اختيار آلات التشكيل المناسبة دراسة شاملة لاحتياجات الإنتاج وخصائص المنتج وميزانية الاستثمار وعوامل أخرى. وفيما يلي بعض الاقتراحات الرئيسية:

1. توضيح احتياجات الإنتاج

- إذا كان مصنعك ينتج بشكل أساسي أدوات مائدة سيراميك كبيرة الحجم وموحدة الحجم، فإن ماكينات كبس السيراميك وخطوط إنتاج تشكيل السيراميك الأوتوماتيكية هي الخيارات المثالية.

- إذا كنت بحاجة إلى إنتاج أدوات مائدة خزفية ذات تصميمات متنوعة ومعقدة، فإن ماكينات القفز وماكينات الصب الانزلاقي ستوفر مرونة ودقة أكبر.

2. النظر في ميزات المنتج

- ماكينة كبس السيراميك: مناسبة لإنتاج منتجات موحدة مثل الأكواب الخزفية والأوعية والأطباق والصحون الخزفية ذات الأشكال المنتظمة والأبعاد الدقيقة.

- ماكينة القفز على السيراميك: مناسبة لإنتاج الأطباق والأوعية وغيرها من المنتجات ذات القوام السطحي المعقد.

- ماكينة صب السيراميك المنزلق: مناسبة لإنتاج أباريق الشاي ذات الجدران الرقيقة وذات الهيكل الدقيق، وأكواب القهوة، والمزهريات وغيرها من المنتجات.

3. تقييم الميزانية الاستثمارية

- الاستثمار الأولي لخط إنتاج صب السيراميك الأوتوماتيكي بالكامل مرتفع نسبيًا، ولكن في التشغيل طويل الأجل، يمكن أن يقلل بشكل كبير من تكاليف العمالة ويحسن كفاءة الإنتاج.

- إن الاستثمار الأولي في ماكينات كبس السيراميك وماكينات القفز على السيراميك وماكينات التشكيل الانزلاقي منخفض نسبيًا وهو أكثر ملاءمة لمؤسسات الإنتاج الصغيرة والمتوسطة الحجم.

4. فهم الدعم الفني

اختر موردًا يتمتع بخدمة جيدة لما بعد البيع والدعم الفني لضمان إمكانية صيانة المعدات وترقيتها في الوقت المناسب أثناء الاستخدام. شركة Yutai لتصنيع ماكينات السيراميك، متخصصة في إنتاج ماكينات السيراميك لأكثر من 20 عامًا، وتوفر خدمة احترافية حلول مصانع السيراميك إلى أكثر من 100 دولة. مرحبًا بكم في الاتصال بنا لمعرفة المزيد عن الدعم الفني.

الخاتمة

ماكينات تشكيل السيراميك هي المعدات الأساسية لإنتاج منتجات السيراميك. من الضروري اختيار آلة التشكيل المناسبة بناءً على ظروف المصنع الخاص بك. كما الشركة المصنعة لآلات السيراميك، نحن ملتزمون بتزويد العملاء بأعلى مستويات الجودة ماكينات السيراميك والدعم الفني الشامل لمساعدة العملاء على تحسين كفاءة الإنتاج وخفض التكاليف واكتساب مزايا تنافسية في السوق.

إذا كنت تريد معرفة المزيد عن ماكينات تشكيل السيراميك أو طلب المشورة والحلول المهنية، لا تتردد في الاتصال بنا. دعونا نعمل معًا لتعزيز الابتكار والتطوير في صناعة أدوات المائدة الخزفية!