Along with global ceramic producers orienting to machinery-based, mass, high-value-added production, more overseas investors are attracted by the turnkey ceramic production line solution. Compared with buying a single machine, a turnkey solution helps to mitigate project risks, speed up commissioning, and guarantee long-term stable production.

However, a ceramic production line project is complex, involves multiple machines, and requires significant investment. Without proper planning, issues such as unstable output, inconsistent quality, or delivery delays can arise. This guide provides a comprehensive checklist for foreign investors to evaluate turnkey ceramic projects and explains why يوتاي is the preferred partner for complete factory solutions.

Why Foreign Investors Prefer Turnkey Ceramic Production Lines?

The biggest challenge in overseas ceramic factory projects is not the performance of a single machine, but system integration and overall project delivery. Multi-vendor solutions may appear cost-effective initially, but often lead to:

- Incompatible equipment interfaces and processes

- Long commissioning periods due to uncoordinated control systems

- Ambiguous responsibilities and complex after-sales support

A turnkey ceramic production line approach, managed by a single الشركة المصنعة لآلات السيراميك, ensures a smooth, integrated solution. يوتاي combines system design, equipment manufacturing, and line integration expertise, offering investors a one-stop solution for global ceramic projects.

Checklist 1: Clear Project Objectives and Product Planning

Before purchasing equipment, investors must define project goals:

- What types of ceramic products will be produced? Tableware, sanitary ware, planters, mugs, or industrial ceramics?

- Are the products for local markets or for export?

- What are the expected output, product quality, and automation levels?

Different products and markets require tailored ceramic production line solutions. Yutai assists clients in process evaluation and capacity planning to ensure accurate line design from the start.

Checklist 2: Systematic Planning of the Ceramic Production Process

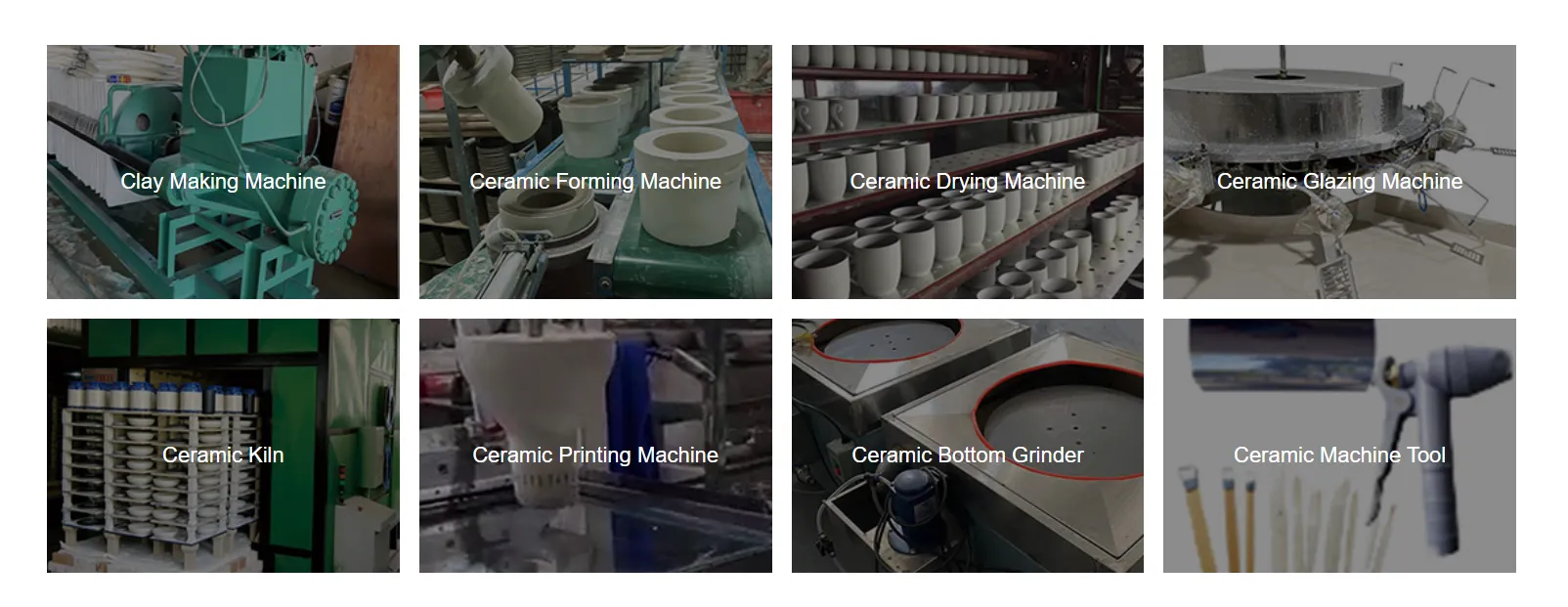

A complete خط إنتاج السيراميك typically includes:

- Raw material preparation and clay processing

- Forming machine(pressing, slip casting, jiggering, or automatic forming lines)

- Automatic ceramic drying machine

- Ceramic glazing and coating machine

- Kiln firing (roller kiln, tunnel kiln, shuttle kiln)

- Ceramic printing and decoration machine

- Bottom grinder and finishing

Many project failures are due to poor process integration, not machine quality. Yutai’s turnkey solutions ensure seamless process continuity and stable production from raw material to finished product.

Checklist 3: Core Machines Supplied by a Single System Provider

Mixing multiple brands in a ceramic line increases risk. Differences in machine design, control systems, and process understanding can compromise stability.

يوتاي provides core equipment covering the full ceramic production process:

- Forming machines (press, slip casting, automatic forming lines)

- Automatic drying systems

- Glazing and coating machines

- Ceramic kilns (roller, tunnel, shuttle)

- Printing and decoration machines

- Bottom grinding and finishing equipment

Unified manufacturing and system integration ensure line consistency and reliable long-term operation.

Checklist 4: Automation and Control Systems

Automation must be considered in the line design stage rather than added later. A unified PLC control system helps:

- Reduce labor dependency

- Improve product consistency

- Minimize operator errors

Yutai’s turnkey ceramic production lines integrate centralized control and process data linkage for higher efficiency and consistent quality.

Checklist 5: Factory Layout Optimized for Turnkey Production

Proper factory layout impacts efficiency, logistics, and personnel workflow. Yutai’s turnkey services include:

- Factory layout recommendations

- Equipment installation sequence planning

- Optimized material and operator flow

This reduces later modifications and supports smooth production.

Checklist 6: Pre-shipment Assembly and Testing

For overseas projects, pre-assembly and testing are essential. At Yutai’s modern facility, complete ceramic production lines can be assembled, integrated, and tested before shipment, resulting in:

- Shorter on-site installation times

- Reduced commissioning risks

- Faster ramp-up to full production

Checklist 7: Delivery, Installation, and Long-Term Support

Turnkey projects require ongoing support. يوتاي يوفر:

- Installation guidance

- On-site commissioning assistance

- Operator training

- Continuous technical support and upgrades

Investors benefit from reduced risks and reliable production compared to single-machine suppliers.

Why Choose Yutai as Your Turnkey Ceramic Machinery Partner?

- Full-process ceramic machinery manufacturing expertise

- Extensive overseas turnkey project experience

- Combined equipment manufacturing and engineering integration capability

- Expanded production capacity and delivery assurance from the new facility

These strengths make يوتاي the trusted ceramic factory turnkey solution provider for foreign investors.

الخاتمة

A clear turnkey ceramic production line checklist helps investors mitigate risks, streamline commissioning, and achieve higher ROI. Yutai, an experienced ceramic machinery supplier, ensures a smooth, reliable, and technically sound path from planning to operation. اتصل بنا today to discuss customized turnkey ceramic production line solutions and get a professional evaluation for your ceramic factory project.