In recent years, the competitive logic of the ceramic manufacturing industry has been quietly changing. Competition is no longer driven purely by production capacity or price, but increasingly by delivery stability, product differentiation, and customization capability. Against this backdrop, many ceramic factory owners and investors are asking a critical question: Is investing in a ceramic decal printing machine still profitable in 2026, or has it become an unnecessary cost? Yutai analyzes the issue from a cost structure and ROI perspective, helping ceramic manufacturers evaluate whether decal printing should remain—or become—a core in-house capability.

Ceramic Decal Market Trends Heading into 2026

Globally, demand for ceramic decals is not declining. Instead, it is becoming more segmented and value-driven. In tableware, decorative ceramics, and sanitary ware, custom patterns, series designs, and brand-specific decoration are increasingly essential. At the same time, overseas buyers are shifting toward:

- Smaller order quantities

- More frequent design updates

- Shorter delivery cycles

Under these conditions, ceramic factories that rely entirely on outsourced decal printing often face:

- Unstable and rising costs

- Longer and less predictable lead times

- Higher risks of color deviation and rework

As a result, more manufacturers are reconsidering whether in-house ceramic decal printing is still a strategic advantage.

What Role Does a Ceramic Decal Printing Machine Play in Production?

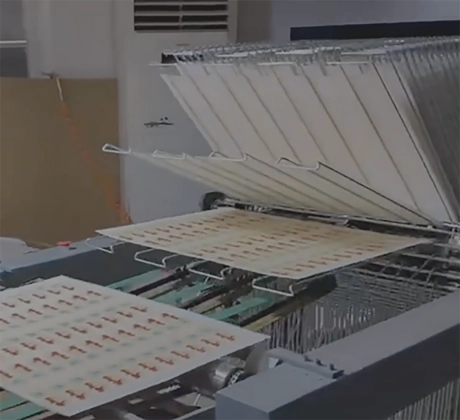

Ceramic decal printing is not an isolated process. It is a key decoration stage within the overall ceramic manufacturing workflow.

A typical process includes:

Design artwork → Decal paper printing → Application → Kiln firing

The ceramic decal printing machine directly determines:

- Print accuracy and edge definition

- Color consistency across batches

- Stability during decal transfer and firing

Compared with manual or outsourced methods, automatic ceramic decal printing machines provide process stability and repeatability, which are essential for modern ceramic factories operating at scale.

Cost Structure of Ceramic Decal Printing in 2026

Before evaluating profitability, manufacturers must understand the true cost components.

Equipment Investment

A ceramic decal printing machine is a one-time capital investment. Costs vary depending on automation level, printing width, production capacity, and customization requirements.

When amortized over years of operation, the equipment cost becomes a long-term production asset rather than a short-term expense.

Labor Cost Optimization

Traditional decal printing often requires skilled operators and intensive manual involvement, leading to:

- Higher labor headcount

- Strong dependency on experienced workers

- Inconsistent output quality

Automatic decal printing machines significantly reduce labor dependency, allowing:

- Fewer operators per shift

- More standardized operation

- Improved productivity per worker

In 2026, when labor costs continue to rise globally, this shift will have a direct impact on profitability.

Material Waste and Yield Loss

While decal paper and inks are recurring costs, waste caused by unstable printing is often overlooked.

Printing inaccuracies can result in:

- Misalignment

- Color inconsistency

- Failed transfers after firing

Automated equipment minimizes these losses through stable parameter control, directly improving yield rates.

Operation and Maintenance Costs

Compared with kilns or forming machines, ceramic decal printing machines have relatively manageable maintenance requirements.

Stable mechanical design and reliable control systems play a key role in keeping long-term operating costs predictable.

ROI Analysis: How Long Does It Take to Recover the Investment?

The profitability of a ceramic decal printing machine depends on payback time, not just purchase price.

ROI typically comes from:

- Reduced outsourcing expenses

- Lower defect and rework rates

- Increased order acceptance capacity

- Higher product added value

In practice, payback periods vary by factory type:

- Tableware factories benefit from steady mid-volume production

- Sanitary ware manufacturers gain from high utilization and consistent demand

- Custom ceramic producers often achieve faster ROI through premium products

The key factor is not whether ROI exists, but whether the machine matches the factory’s order structure and production strategy.

Which Ceramic Factories Benefit Most in 2026?

Not every factory needs immediate investment. However, ceramic decal printing machines are particularly suitable for manufacturers that:

- Focus on export markets

- Handle multiple patterns and frequent design changes

- Are transitioning from manual to automated production

- Aim to improve delivery reliability and cost control

For these factories, ceramic decal printing becomes a core production capability, not just an auxiliary process.

Why Automation Is Replacing Traditional Decal Printing Methods?

Automation is not about appearing advanced—it is about solving real production challenges.

Automatic ceramic decal printing offers:

- More consistent quality output

- Predictable production schedules

- Easily replicable printing standards

In a market where delivery performance and consistency define competitiveness, automation becomes a necessity rather than a luxury.

How Yutai Helps Improve ROI in Ceramic Decal Printing?

As a ceramic machinery manufacturer, Yutai focuses on application-based solutions, not just standalone equipment.

Yutai supports ceramic factories by:

- Customizing decal printing machines based on product types

- Integrating equipment into existing production lines

- Providing stable solutions for export-oriented factories

- Designing scalable systems for long-term growth

The goal is to ensure that decal printing equipment delivers measurable value within the entire production system.

Conclusion

In 2026, ceramic decal printing machines are not inherently costly or profitable—the outcome depends on how they are used.

When decal printing is enabled:

- Higher product differentiation

- Better delivery control

- Stronger customization capability

It becomes a strategic investment, not a cost burden. For ceramic manufacturers planning their next 3–5 years, now is the right time to reassess whether in-house decal printing should be part of their competitive strategy.

If you would like to discuss your production requirements, ROI expectations, or equipment configuration, feel free to contact us for technical consultation and tailored solutions. Yutai works closely with ceramic manufacturers worldwide to provide customized ceramic decal printing solutions, from standalone machines to integrated production lines.