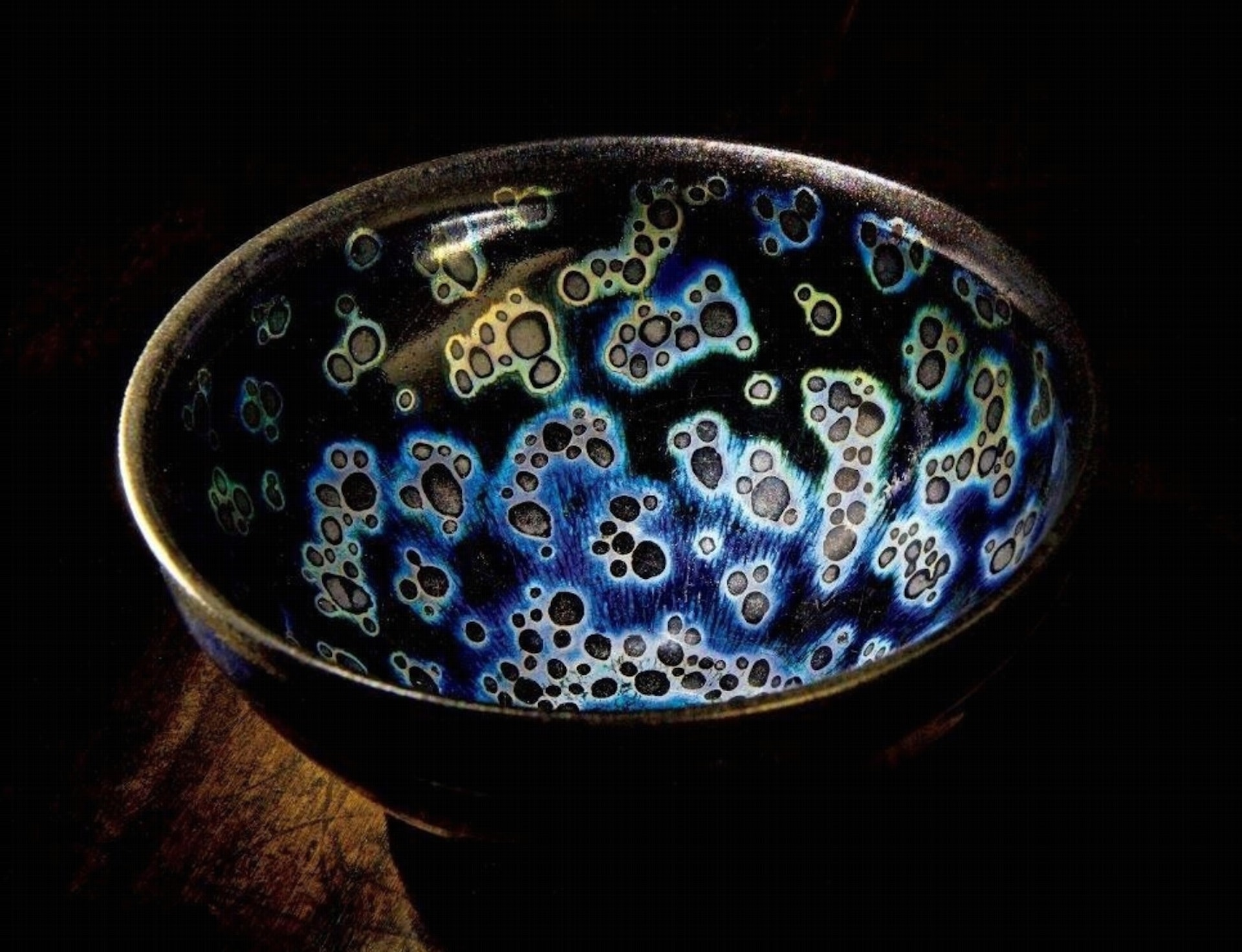

Although colored glaze ceramics are gaining more popularity in all global markets, their manufacturing requires much higher precision compared to traditional glazing. This not only refers to achieving consistent color, but also stable glaze thickness and defect-free surfaces. In this respect, finding the right ceramic glazing machine becomes decisive for manufacturers who want to scale up their output or upgrade product quality. This article provides a practical guide to choosing suitable glazing machine for colored glaze ceramics, helping factories improve efficiency, reduce defects, and achieve stable mass production.

Why Colored Glaze Ceramics Require Specialized Glazing Equipment

Colored glaze has different viscosity, particle content, and adhesion characteristics compared with transparent glaze or traditional glazes. This leads to several production challenges:

- Strict requirement for glaze uniformity to avoid color variations.

- Higher viscosity that may clog nozzles or affect spray stability.

- Color sensitivity that makes glaze distribution more visible on the final product.

- Complex shapes that require multi-angle spraying.

- Batch consistency, especially for high-volume production.

Manual glazing is no longer suitable for large-scale production because it increases the risk of thin spots, glaze sagging, uneven color patches, and high defect rates. Therefore, investing in a professional glazing machine is essential for industrial-grade colored glaze manufacturing.

Key Factors to Consider When Choosing a Glazing Machine for Colored Glaze Ceramics

Glaze Application Uniformity and Pressure Stability

The core requirement is whether the machine can maintain stable spray pressure, glaze flow rate, and particle distribution. Look for:

- Precision-controlled pumps

- Stable pressure regulation system

- Consistent spray fan shape

- Sensors and feedback control for real-time adjustments

These features directly impact glaze thickness and color consistency.

Compatibility With Colored Glaze Properties

Colored glaze usually contains higher viscosity and pigment load. A suitable machine should:

- Support a wide viscosity range

- Prevent nozzle clogging

- Allow adjustable flow and atomization settings

- Offer specialized spray heads if needed

Tip: Ask the supplier whether the machine can test your glaze samples before purchase. This is essential for exporters handling multiple glaze formulas.

Adaptability to Different Ceramic Shapes and Sizes

A flexible machine is crucial for manufacturers producing various product types. Look for:

- Adjustable spray arms

- Multi-angle spraying

- Flexible turntable or conveyor width

- Support for bowls, plates, bottles, vases, tiles, and irregular shapes

This reduces downtime and improves production turnover.

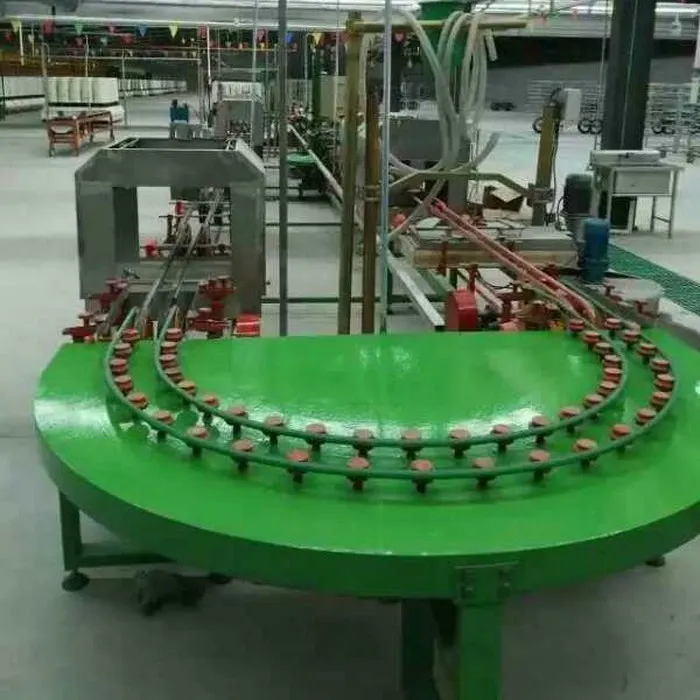

Automation Level and Production Capacity

For B2B ceramic manufacturers, automation helps maintain consistent quality and high output. Evaluate:

- Pieces-per-hour capacity

- PLC automation settings

- Integration with ceramic production line equipment

- Repeatable glazing recipes for consistent batches

Ease of Cleaning and Color-Switching Efficiency

Since colored glaze production often requires frequent color changes, a good machine should offer:

- Quick-clean glaze tanks

- Easy-to-remove nozzles

- Low glaze waste

- Short color-switching cycles

These features greatly reduce downtime and improve overall productivity.

After-Sales Service, Spare Parts, and Long-Term Stability

Because glazing machines are long-term assets, consider:

- Availability of spare parts

- Technical support response speed

- Remote troubleshooting capability

- Training support

For overseas factories, reliable technical support ensures continuous production.

Types of Glazing Machines and Their Ideal Applications

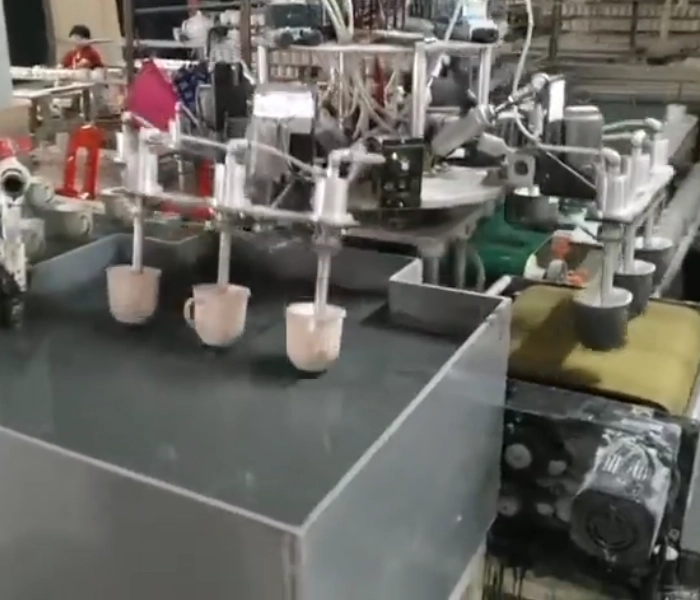

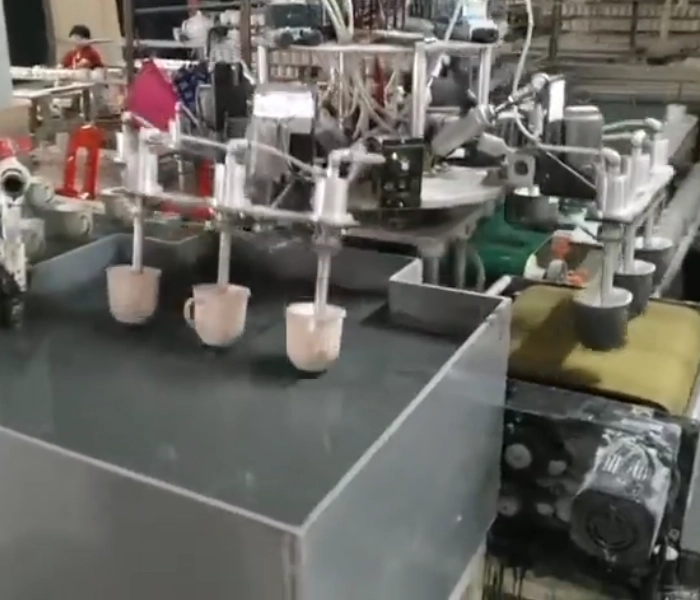

Automatic Glazing Machine

Best for large factories producing dinnerware, tiles, or daily-use ceramics.

Advantages: High speed, excellent uniformity, low labor cost.

Semi-Automatic Glazing Machine

Suitable for small and medium-sized manufacturers.

Advantages: Flexible, user-friendly, cost-effective.

Robotic Glazing System

Ideal for high-end colored glaze or complex-shaped ceramics.

Advantages: Highest precision, customizable spray angles, superior consistency.

Questions to Ask Before Purchasing a Glazing Machine

- Can the machine handle my glaze viscosity and color glaze formula?

- How uniform is the glaze thickness? Can you test my samples?

- What is the hourly production capacity?

- How fast is color switching and cleaning?

- Can it integrate with my existing ceramic production line?

- What warranty and after-sales support are provided?

Why Ceramic Manufacturers Choose Yutai Machinery

As a professional ceramic machinery manufacturer, Yutai offers glazing solutions designed specifically for colored glaze ceramics. Key advantages include:

- Equipment optimized for high-viscosity, pigment-rich glazes

- Advanced spray control for uniform and stable glazing

- Compatibility with varied ceramic shapes and sizes

- Full ceramic production line integration: glazing, drying, conveying, firing

- Reliable global technical service and customization options

Whether you need an automatic glazing machine, a semi-automatic system, or a robotic solution, Yutai provides reliable machinery backed by years of industry experience.

Conclusion

Choosing the right glazing machine for colored glaze ceramics requires understanding glaze characteristics, production capacity, automation needs, and maintenance requirements. The right equipment can significantly reduce defects, improve consistency, and boost production efficiency. If you are planning to upgrade your glazing system or need customized equipment, welcome to contast Yutai, we can provide professional evaluation and tailored ceramic equipment solutions.