In today’s ceramic market, product homogenization and fierce price wars have pressured the majority of the ceramic manufacturers to maintain profitability. Differentiating with high-end products has become the top agenda of ceramic factories. The custom low-temperature ceramic decals offer ceramic manufacturers the best means to add product value and enhance market competitiveness. With exquisite decal designs, low-temperature firing technology, and flexible customization, not only can the quality of products be enhanced by ceramic manufacturers, but they can also optimize the production efficiency and achieve more satisfactory profit margins.

What is low-temperature decal ceramic?

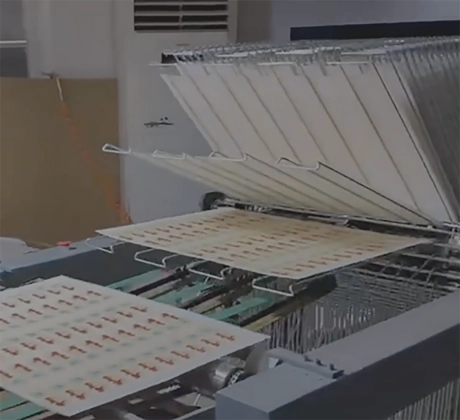

Low-temperature ceramic decals are a kind of material that can be used to decorate ceramics at lower temperatures. Compared to traditional high-temperature decals, they feature lower firing temperatures, better energy efficiency, and maintain the intricacy of the pattern and color stability. They can be used on a wide range of ceramic items, including tableware, tea sets, vases, and glassware. The standard procedure includes printing, transfer printing, and firing, all of which can be accurately controlled with the assistance of professional equipment.

Core Advantages of Low-Temperature Decals

Energy Saving

Low-temperature firing uses less energy compared to high-temperature firing, thereby reducing the cost of production.

Shortened Production Cycle

Low-temperature firing reduces the production cycle, which makes the process more efficient with the ability to deliver large-volume orders within a limited period.

Complicated and Delicate Patterns

Low-temperature decals are capable of creating complicated and delicate patterns, which enhance the aesthetic value of products.

How Low-Temperature Decals Enhance the Value of Products

By utilizing low-temperature decals, ceramic manufacturers can create high-grade decal patterns such as gold thread decoration, relief patterns, and natural and animal motif patterns. These intricate patterns and beautiful color combinations make tableware, tea sets, and other ornamental ceramics more competitive in the market.

Enhancing Product Competitiveness

Unique decal designs can make products more conspicuous compared to their competitors and raise brand awareness. OEM/ODM low-temperature ceramic decals services to meet customers’ demands for customized products and enable ceramic producers to launch distinctive products to different markets.

Reduce defective product rates and stabilize production

Low-temperature decals, along with the better equipment, enable precise control over temperature, which reduces cracking and discoloration during firing and improves yield rates. Stability of the entire production line also ensures efficiency and consistency for mass production.

Common Applications of Low-Temperature Decals

Ceramic Tableware Industry

High-grade plates and tea sets are decorated with low-temperature decals, achieving a luxurious look and unique brand style. Low-temperature decals can more accurately reproduce complex patterns than traditional methods and ensure color fastness.

Home Decor and Gift Ceramics

Low-temperature decals can be applied to a range of materials, such as ceramic and glass, and can be applied to vases, lighting, and decorative ceramics, making it easier for ceramic businesses to enter the high-value-added gift market.

Ceramic Factory

For OEM/ODM orders of ceramic producers, low-temperature ceramic decals can react to tailor-made orders quickly, modify patterns and colors with flexibility, and achieve stable mass production to meet the differentiated needs of different customers and products.

How to Choose the Appropriate Low-Temperature Decals Paper

Material and Heat Resistance

Different ceramics have different firing temperatures for decals. The selection of appropriate material is the key to reaching the best firing results.

Pattern Clarity and Adhesion

Good quality decal paper must ensure bright, clear patterns and good adhesion after firing without fading or discoloring.

Supplier and Customization Capability

The supplier is best selected from someone who can ensure a stable bulk supply and can offer OEM/ODM customization. The supplier’s service capability, sample support, and technical guidance are the most critical in ensuring the success of low-temperature decal applications.

Conclusion

Low-temperature ceramic decal paper brings three key benefits to ceramic manufacturers: enhancing product looks and attracting high-value customers; reducing production cost and defect rate, boosting efficiency and profit; and enhancing market competitiveness, supporting customization and differentiation. Contact us now for Yutai custom low-temperature ceramic decal paper samples and solutions to differentiate your ceramic products!