For ceramic tableware manufacturers, every step from clay to finished product is crucial to quality and production capacity. An automated ceramic production line connects these discrete processes into an efficient closed loop. What is an automated ceramic production line? What are its core components? And what irreplaceable advantages does it offer companies? This article will provide an in-depth analysis to answer these questions.

What is an automated ceramic production line?

An automated ceramic production line uses a series of mechanical equipment and intelligent control systems to achieve continuous, integrated, and intelligent production of multiple key steps in ceramic production. Compared to traditional methods that rely on manual labor and individual machines, automated production lines emphasize:

- Efficiency: Reducing waiting time between processes and achieving continuous operation.

- Quality: Improving product consistency through precise control.

- Intelligence: Leveraging sensors and data systems to monitor and optimize the production process.

Currently, automated ceramic production lines are widely used in the production of ceramic bowls, basins, tiles, art porcelain, and industrial ceramics.

Core Components of an Automatic Ceramic Production Line

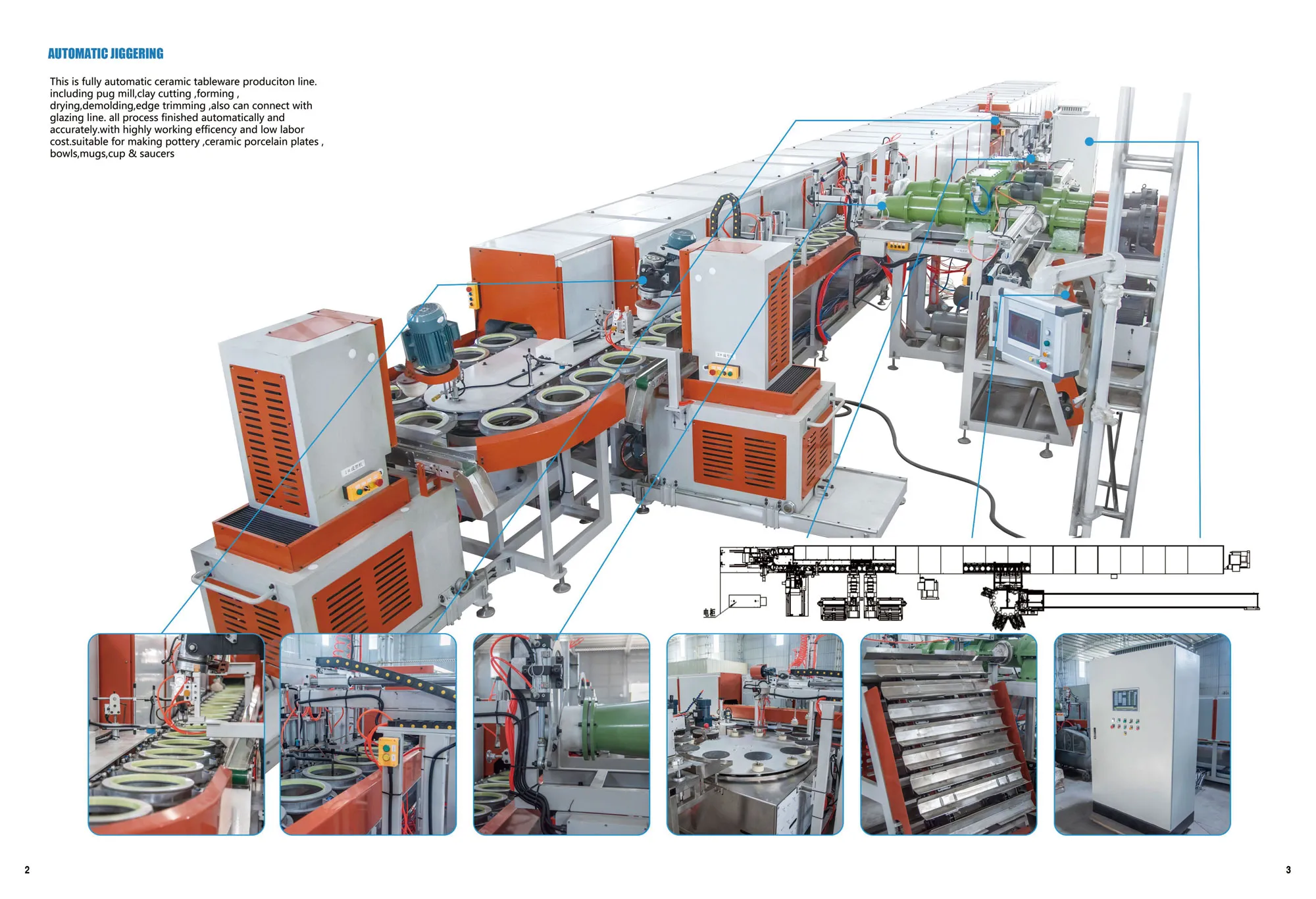

Raw Materials and Forming

Clay Making Machine, Ceramic Forming Machine

Function: Automatically forms ceramic bodies, ensuring consistent dimensions, suitable for large-scale mass production.

Drying

Function: Uniformly removes moisture from the body, preventing cracks or deformation caused by uneven drying.

Firing

Function: Provides a stable, controllable high-temperature environment to ensure the density, strength, and durability of the ceramic.

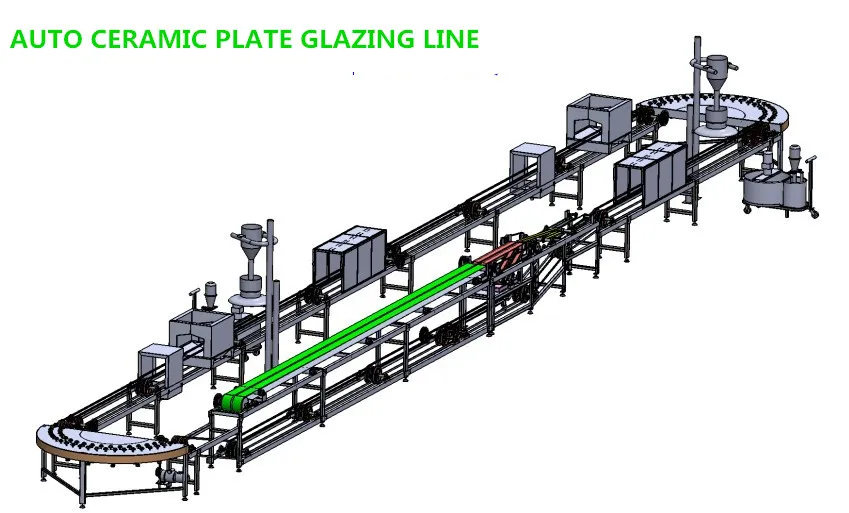

Surface Treatment

Ceramic Glazing Machine, Ceramic Printing Machine

Function: Ensures uniform glaze application and decorative patterns, enhancing product aesthetics and added value.

Finishing

Ceramic Bottom Grinding Machine

Function: Grinds and trims finished products, ensuring dimensional accuracy and user experience.

Auxiliary Systems

Transmission Line, Intelligent Control Platform

Function: Enables equipment linkage and data collection, making production more intelligent and transparent.

Advantages of Automatic Ceramic Production Lines

Improved Production Efficiency

How do automatic ceramic manufacturing machines improve production efficiency? Automatic ceramic production lines enable continuous operation, significantly shortening production cycles and significantly increasing production capacity.

Reduced Labor Costs

Automated equipment reduces reliance on a large number of skilled workers, lowering labor costs while also minimizing losses caused by human error.

Ensured Product Consistency and Stable Quality

Through precise control of process parameters, each ceramic product achieves high consistency and a high pass rate, effectively reducing defective product rates.

Energy Saving and Environmental Protection

Automated production lines offer advantages in energy and material utilization, reducing production costs and aligning with the development trend of green manufacturing.

Support for Intelligent and Digital Upgrades

Utilizing sensors and data systems, automatic ceramic production lines can collect production data in real time, enabling intelligent monitoring, process optimization, and predictive maintenance, laying the foundation for companies to move towards Industry 4.0.

Typical Application Scenarios

With the increasing popularity of automated ceramic production lines, their applications have expanded beyond traditional household ceramics to encompass a wider range of production needs, including tableware, craft ceramics, and even industrial ceramics.

- Ceramic tableware: Efficient production of everyday ceramics such as bowls, plates, and basins.

- Craft ceramics: Large-scale reproduction and decorative process control.

- Industrial ceramics: Meeting the production needs of high-performance, high-precision ceramic products.

Conclusion

The entry of automated production lines for ceramics has brought systematic improvements in efficiency, quality, and intelligence into the world of ceramics. For medium and large-scale factories seeking to increase production capacity or for companies seeking cost reductions and added quality, automated production lines have become a compelling development choice.

As a leading ceramic machinery supplier, Yutai offers customers one-stop ceramic manufacturing solutions from ceramic drying machines, kilns, and glazing machines to comprehensive automated production line solutions, helping ceramic companies enhance their production and understand market opportunities. Welcome to contact us to explore more ceramics manufacturing solutions!