From daily-use tableware to sanitary ware and ceramic insulators, we offer complete ceramic machinery and turnkey solutions with reliable support.

Full Range of Machines

Custom Support

Technical Support

Quality Assurance

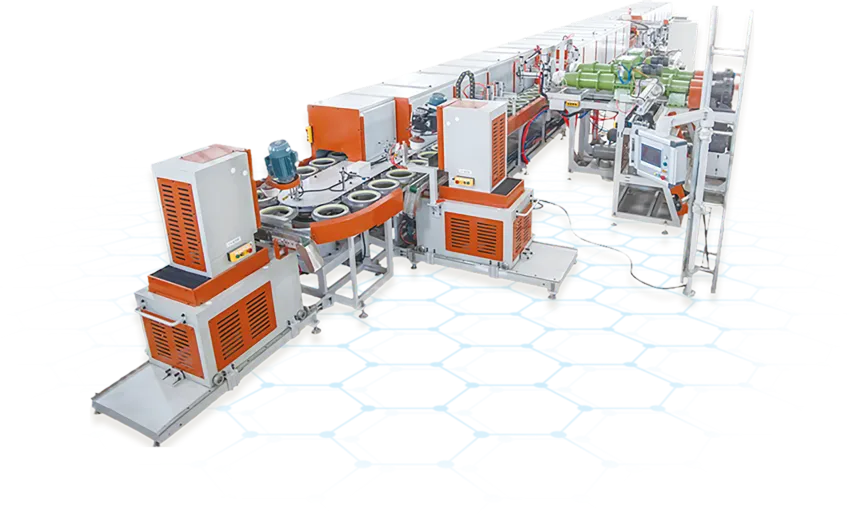

Yutai offers a complete range of ceramic machines for every step of production – from clay making, forming, to glazing, firing, and printing. Our machines deliver reliable performance and flexible solutions tailored to various production needs.

Ball mill, iron removal machine, vibrating sieve, piston pump, pug mill, filter press, clay cutting machine.

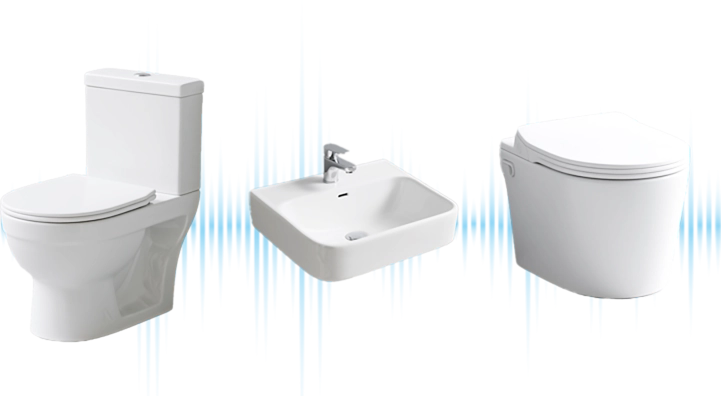

Ceramic press machine, jiggering machine, ceramic slip casting machine, ceramic finishing machine, etc

Energy-efficient drying technology for uniform moisture removal.

Whether for making plates, bowls, mugs, cups, vases, or pots, Our automatic ceramic production line integrates clay processing, forming, drying, demolding, and edge trimming into one streamlined solution.

Customizable high-pressure casting solutions for toilets, wash basins, and bathroom ceramics, delivering fast forming, smooth surfaces, and stable quality to meet different production requirements.

Precision forming machines for industrial and electrical insulating ceramics, designed for high strength, stability, and consistent performance, adaptable to various product specifications.

Founded in 2010, Yutai Machinery specializes in ceramic machine manufacturing with 20+ years of expertise. We serve global clients with innovative machinery, one-stop solutions, and reliable after-sales service, helping ceramic manufacturers achieve higher efficiency and quality.

Whether you are building a new ceramic factory or expanding your production line, our solutions help you improve efficiency, reduce labor costs, and ensure consistent product quality with full technical support.

Covering every stage of production

Machines tailored to meet your specific needs.

Optimize your production flow for maximum efficiency.

Installation, video guidance & after-sales service

Secure packaging & global delivery

At Yutai, our easy cooperation process and global project experience make it simple for manufacturers to start production. Yutai has successfully served clients worldwide and showcased solutions at major ceramic industry exhibitions

Stay updated with the latest insights in ceramic machinery, industry trends, and global market developments.

Tell us your production needs, and we will provide you with a customized ceramic machinery solution.