In the competitive landscape of ceramic production, balancing intricate design with mass-production efficiency is a constant challenge. Our 22m Auto Hollow Casting Production Line is an industrial-grade solution specifically engineered for the high-precision forming of complex, thin-walled, and special-shaped ceramic parts.

Why Upgrade to Automated Slip Casting?

Traditional dry pressing often struggles with complex geometries. Our automated grouting line bridges this gap by offering:

- Superior Shape Adaptability: Easily forms ceramic parts with complex curved surfaces and porous thin walls.

- Full-Process Automation: From automatic slurry supply to cleaning and demolding, the system supports stable 24-hour continuous operation.

- Maximum Cost Efficiency: The system features a slurry recycling rate exceeding 95%, significantly reducing raw material waste.

- High Precision & Quality: Precise control over grouting pressure, temperature, and humidity eliminates common defects like cracking and air bubbles.

Technical Specifications

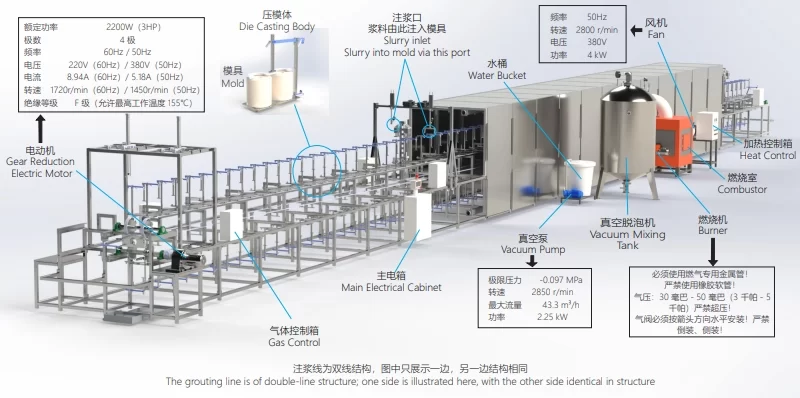

Designed with a high-capacity double-line structure, this machine maximizes output while maintaining a compact factory footprint.

| Feature | Specification |

| Total Line Length | Approx. 23.85 Meters |

| Total Mold Capacity | Up to 238 molds (Double-sided, 400mm spacing) |

| Single-side Chain Length | 47.6 Meters |

| Heating Capacity | 50,000 kcal |

| Total Power | 22 kW |

| Vacuum Pressure | -0.097 MPa (Limit Pressure) |

| Circulating Air Volume | $2800m^{3}/h$ |

Key System Components

- Slip Casting & Slurry Extraction Zone: Utilizes a high-performance vacuum pump (-0.097 MPa) and a vacuum mixing tank to ensure air-free slurry injection.

- Drying Section: Features a dedicated combustor and burner system (50,000 kcal) for controlled, gradient drying of the green bodies.

- Power & Transmission: Driven by a robust electric motor (2200W/3HP) with gear reduction for smooth, consistent chain movement.

- Green Body Extraction: Optimized for safe and efficient removal of the finished products before the mold returns for cleaning.

Troubleshooting & Quality Assurance (FAQ)

We provide comprehensive guidance to ensure your production remains defect-free:

- Preventing Blisters/Pinholes: Ensure sufficient slurry mixing or use the integrated vacuum degassing treatment.

- Solving Uneven Thickness: Periodically inspect mold cavities for deformation and ensure molds are perfectly level.

- Avoiding Cracks: Use gradient drying to reduce temperature and air velocity during the initial drying stage to prevent inconsistent shrinkage.

Export-Ready Safety & Control

Our machines are built for the international market, featuring a Main Electrical Cabinet and a Gas Control Box designed for easy maintenance.

Note: For safety, gas connections must use dedicated metal pipes; rubber hoses are strictly prohibited to ensure compliance with industrial safety standards.

Would you like me to generate a formal Quotation Template or a Technical Data Sheet based on these specifications to send to your international leads?